Recovery and purification method for waste oil

A purification method and waste oil technology, which is applied in recycling technology, fatty substance recovery, and fat oil/fatty acid recovery from waste, etc., can solve the problem that waste oil collection, recovery and purification are not paid attention to, there is no set of standardized technologies, and the environment is affected and other issues to achieve the effects of cost reduction, life expectancy improvement and environmental sanitation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

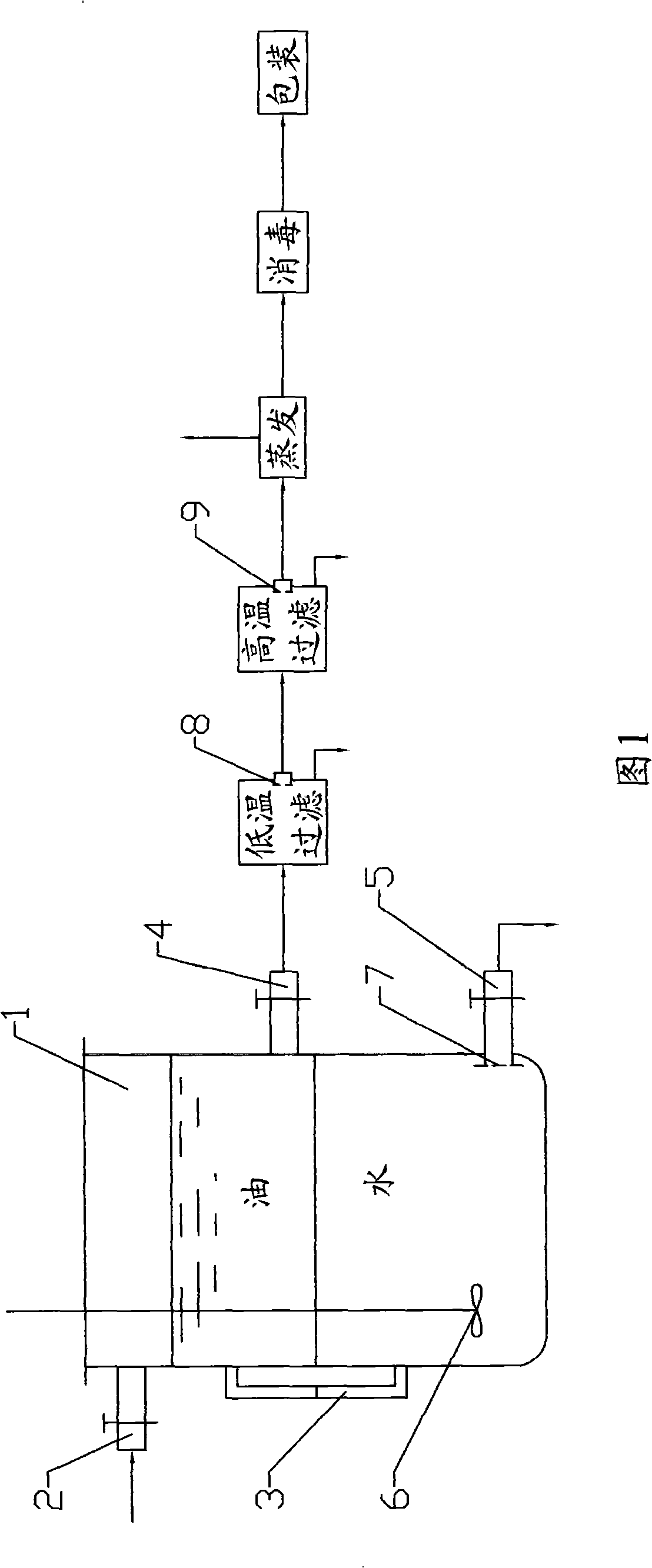

[0018] Fig. 1 has shown a kind of embodiment of the present invention, there is waste oil inlet 2 on the top of recovery separation tank 1, liquid level gauge 3 is arranged in the tank wall middle part, oil outlet valve 4 is housed at the height of liquid level gauge, in The lower part of the tank body is equipped with a waste water outlet valve 5, an agitator 6, a waste water filter screen 7, a low temperature filter screen 8, and a high temperature filter screen 9. The heater installed in the low-temperature filter tank and the high-temperature filter tank is an electric heater or a steam heater, and a waste residue discharge pipe is installed at the bottom of the tank. The sterilizer can be a high-pressure sterilizer or an ultraviolet sterilizer. The waste residue discharged in this process can be used as soil fertilizer after fermentation.

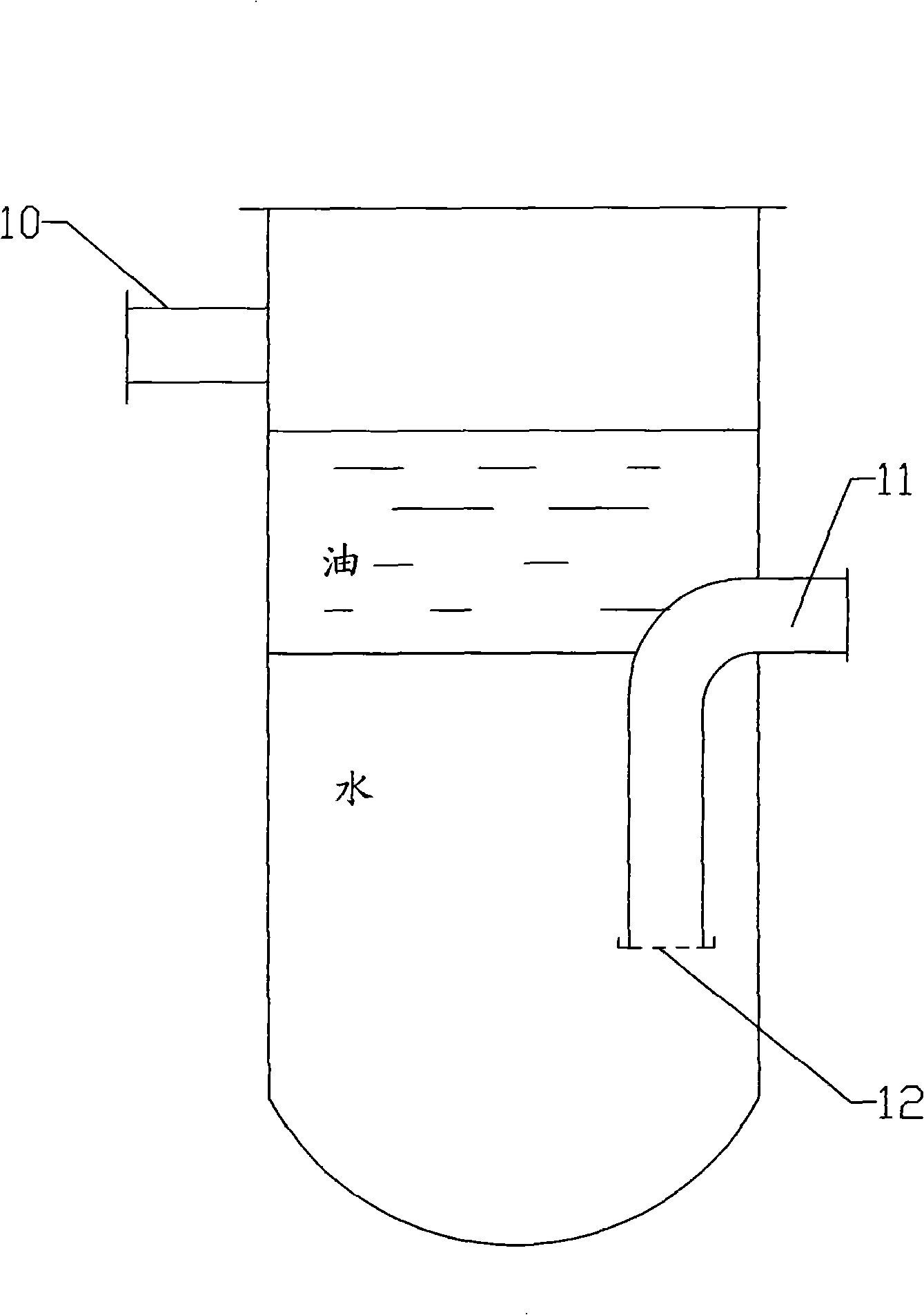

[0019] figure 2 It shows the structure of the well-type oil-water separation device, which is built by using an underground well, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com