Method for preparing nano-Cu uniformly coated Zn4Sb3 powder

A nano and powder technology, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problem of uniform distribution of nano second phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

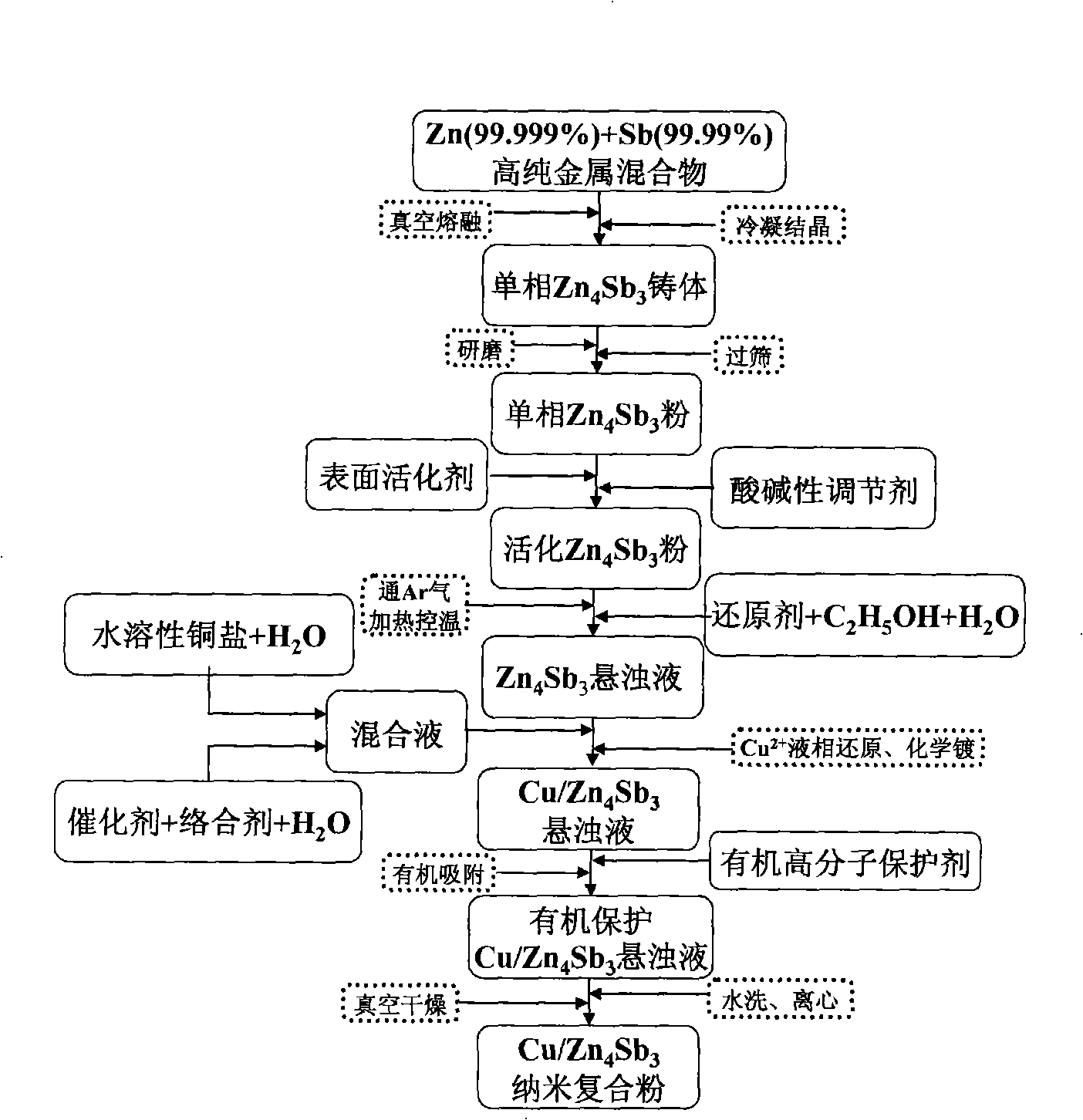

[0046] A Zn uniformly coated with nano-Cu 4 Sb 3 The preparation method of powder, it comprises the steps:

[0047] 1) Preparation of single-phase β-Zn by melting method 4 Sb 3 Powder:

[0048] (1) According to the nominal composition, it is Zn 4.1 Sb 3 Calculation and synthesis of 60g single-phase β-Zn 4 Sb 3 Compounds require high-purity metal Zn powder and high-purity metal Sb powder to be 25.3992g and 34.6364g respectively. Weigh the two raw materials accurately and mix them evenly. -1 In the vacuum quartz tube of MPa, the purity of the high-purity metal Zn powder is more than or equal to 99.999% (mass), and the purity of the high-purity metal Sb powder is more than or equal to 99.99% (mass);

[0049] (2) The above-mentioned vacuum quartz tube is placed in a melting furnace, raised from room temperature to 1023K at a heating rate of 1K / min, melted in vacuum for 2 hours, and cooled to room temperature with the furnace to obtain the required single-phase β-Zn 4 Sb ...

Embodiment 2

[0063] A Zn uniformly coated with nano-Cu 4 Sb 3 The preparation method of powder, it comprises the steps:

[0064] 1) Preparation of single-phase β-Zn by melting method 4 Sb 3 Powder: with embodiment 1.

[0065] 2) Nano-Cu uniformly coated Zn 4 Sb 3 Powder preparation:

[0066] (1) Weigh single-phase β-Zn 4 Sb 3 Powder 10g, ie m 1 =10g, according to single-phase β-Zn 4 Sb 3 The ratio of the powder to the acidic surfactant of pH=5 is 10g: 100ml, and 100ml of the acidic surfactant is weighed, and the single-phase β-Zn 4 Sb 3 The powder is added to the acidic surfactant with pH=5, under the action of magnetic stirring, the single-phase β-Zn 4 Sb 3 The powder was treated with an acidic surfactant for 10 minutes to obtain a suspension; then the molar concentration was 1×10 -3 mol / L acid-base regulator adjusts the pH value of the suspension to 8 to obtain activated β-Zn 4 Sb 3 powder suspension; the acidic surfactant is an aqueous solution of nitric acid, its pH=5;...

Embodiment 3

[0077] A Zn uniformly coated with nano-Cu 4 Sb 3 The preparation method of powder, it comprises the steps:

[0078] 1) Preparation of single-phase β-Zn by melting method 4 Sb 3 Powder: with embodiment 1.

[0079] 2) Nano-Cu uniformly coated Zn 4 Sb 3 Powder preparation:

[0080] (1) Weigh single-phase β-Zn 4 Sb 3 Powder 10g, according to single phase β-Zn 4 Sb 3 The ratio of the powder to the acidic surfactant of pH=5 is 10g: 100ml, and 100ml of the acidic surfactant is weighed, and the single-phase β-Zn 4 Sb 3 The powder is added to the acidic surfactant with pH=5, under the action of magnetic stirring, the single-phase β-Zn 4 Sb 3 The powder was treated with an acidic surfactant for 15 minutes to obtain a suspension; then the molar concentration was 1×10 -3 mol / L acid-base regulator adjusts the pH value of the suspension to 8 to obtain activated β-Zn 4 Sb 3 powder suspension; the acidic surface active agent is an aqueous solution of hydrochloric acid, its pH=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com