Lange coupler bridle wire structure and implementing method

An implementation method and a coupler technology, applied in the field of couplers, can solve the problems of difficult implementation, easy falling off of gold wires, unfavorable rapid production, etc., and achieve the effects of simple implementation method, good anti-vibration effect and excellent electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

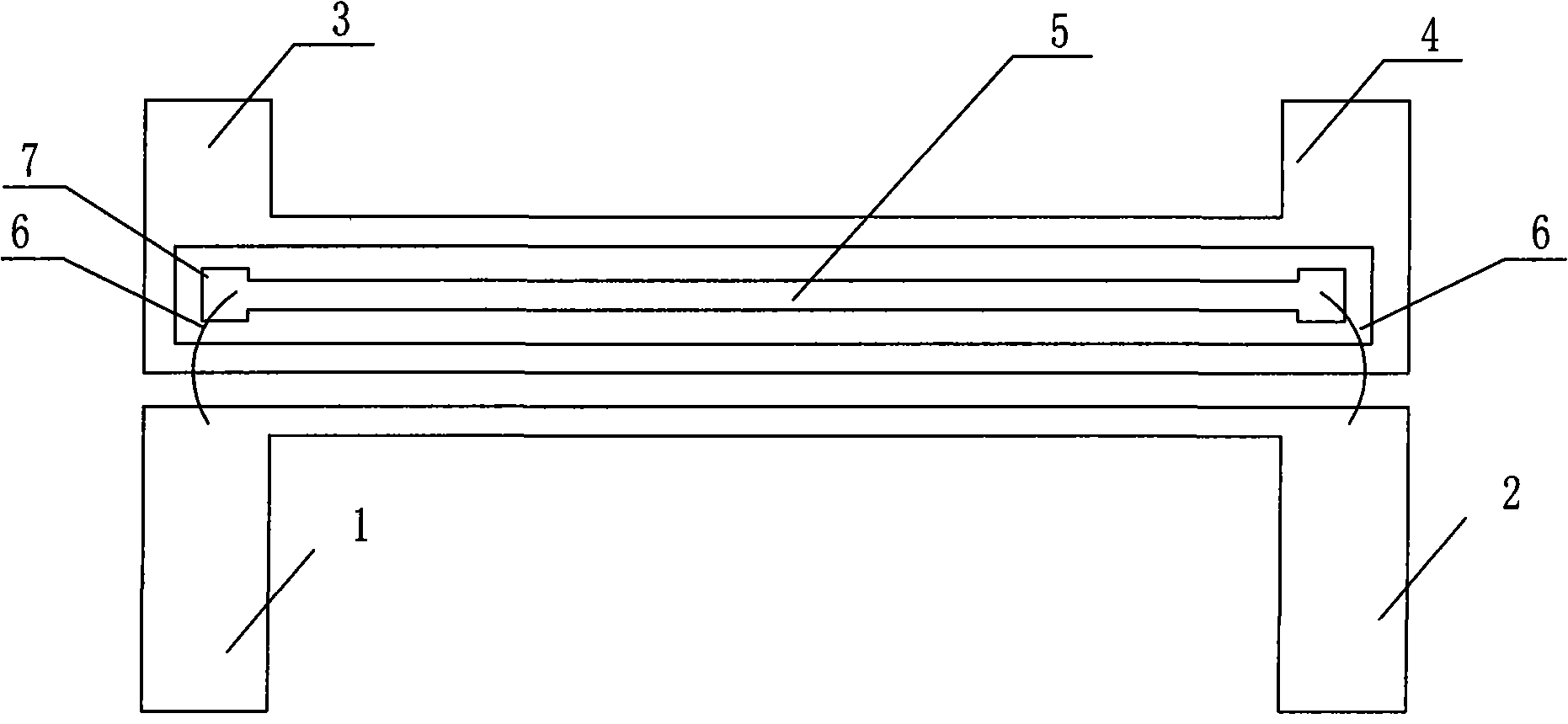

[0017] Embodiment 1: as figure 1 As shown, the Lange coupler jumper structure mainly includes an input port 1, a through port 2, a coupling port 3 and an isolation port 4, and the input port 1, the through port 2, the coupling port 3 and the isolation port 4 are respectively connected to The copper wires 5 are connected, and a jumper 6 for connection is provided between the copper wires 5 , and a pad 7 is provided at the connection between the jumper 6 and the copper wire 5 . The coupling port 3 and the isolation port 4 form an inner cavity, and the input port 1 and the through port 2 are respectively connected to the copper wire segment in the inner cavity through a jumper wire 6 .

Embodiment 2

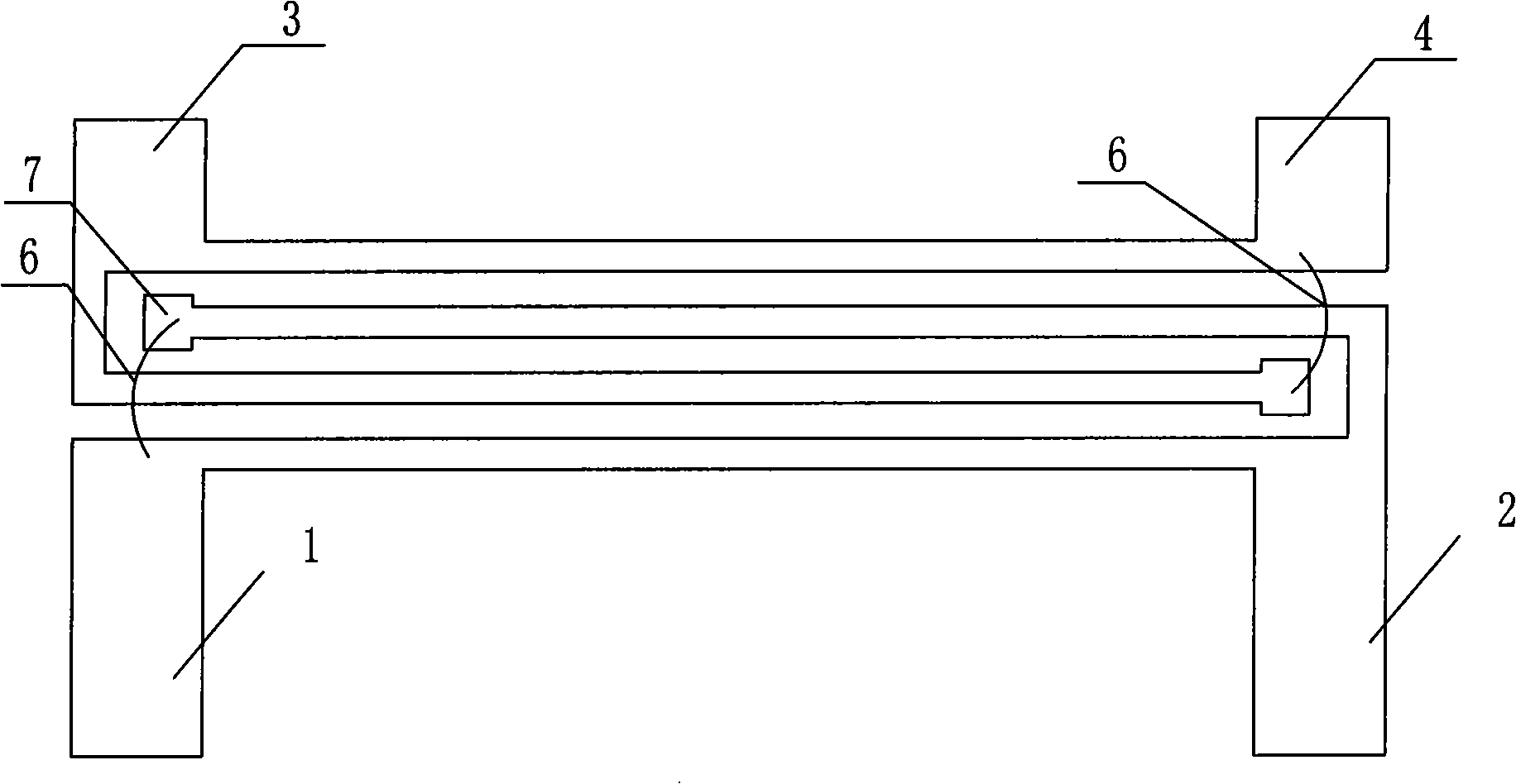

[0018] Example 2, as figure 2 As shown, the copper wire of the input port 1 is connected with the copper wire of the through port 2 through the jumper 6, and the copper wire of the input port 1 is connected with the copper wire of the isolation port 4 through the jumper 6.

Embodiment 3

[0019] Example 3, such as image 3 As shown, the copper wire of the input port 1 is connected to the copper wire of the through port 2 through a jumper 6 , and the copper wire of the coupled port 3 is connected to the copper wire of the isolation port 4 through a jumper 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com