Combustion driven three-dimensional physical analogue device

A physical simulation and three-dimensional technology, applied in teaching models, production fluids, instruments, etc., can solve the problems that affect the development prospect of fire flooding oil recovery technology, cannot explore the fire flooding mechanism in depth, and has little guiding role in on-site reservoir management. Achieve the effects of wide distribution of measuring points, easy maintenance, and strong safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

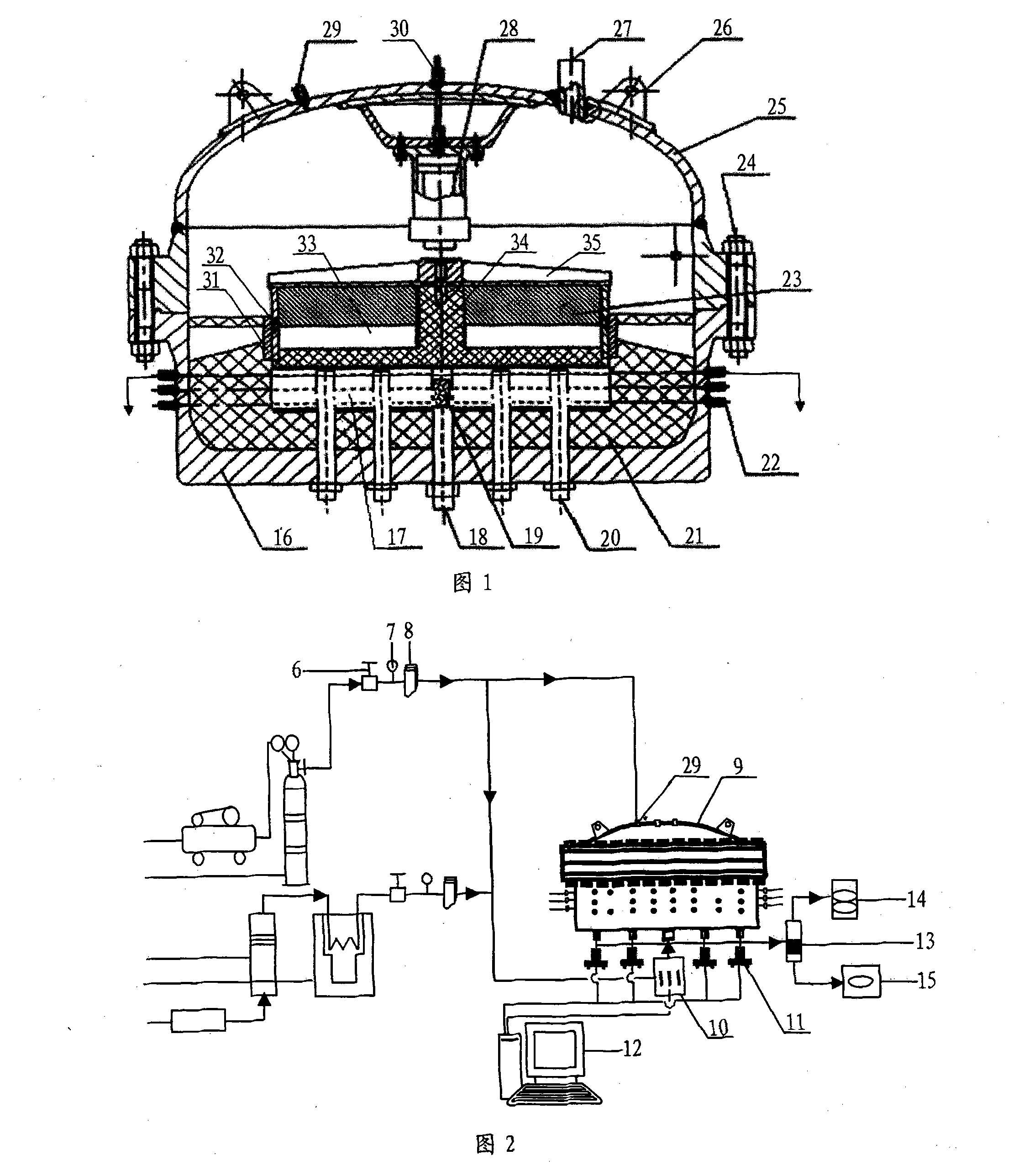

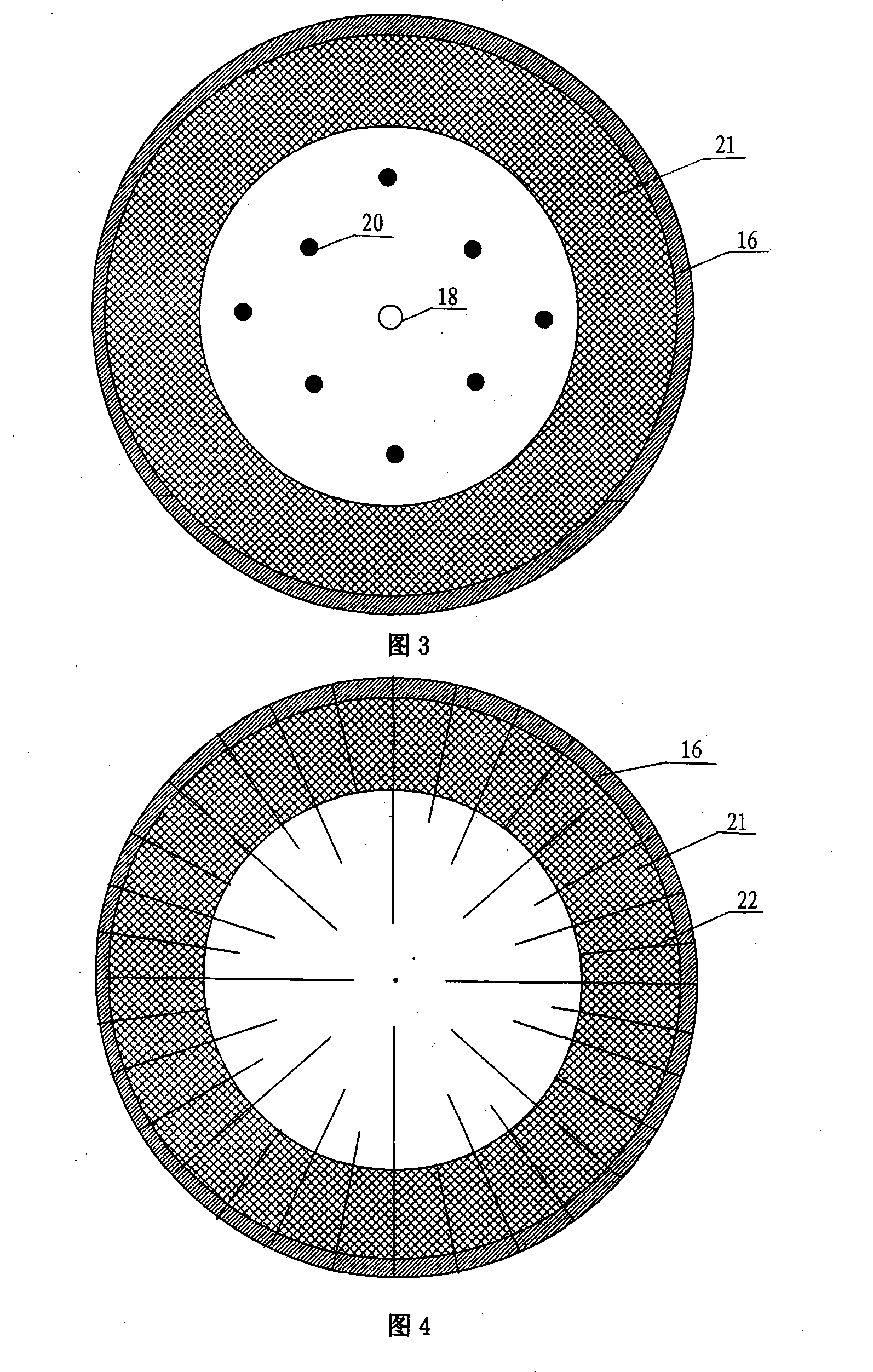

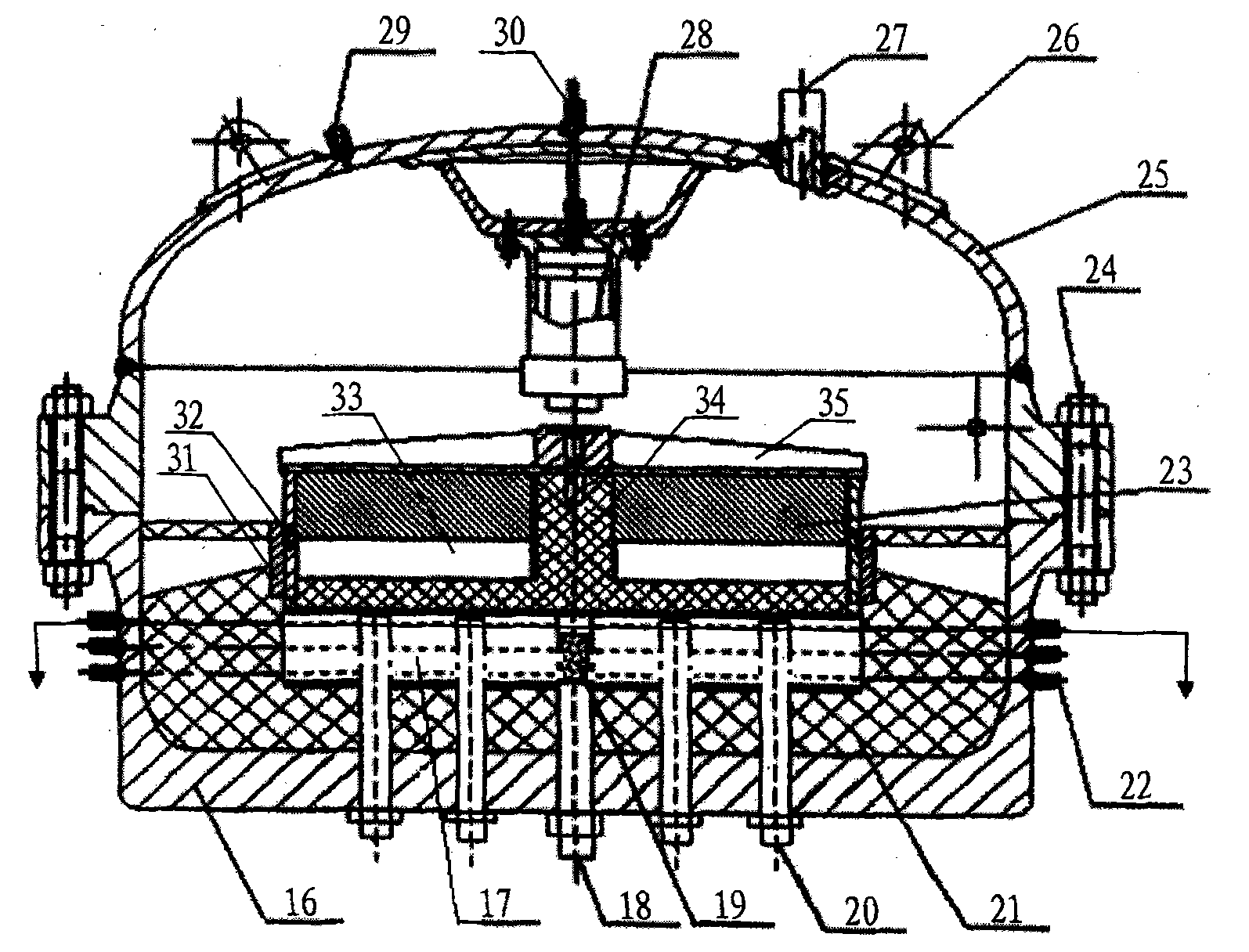

[0016] Referring to Fig. 1-Fig. 4, a three-dimensional physical simulation device for oil displacement by combustion includes an injection system, a simulation body, a measurement and control system and an output analysis system. The injection system includes an air compressor 1, a pressure regulator bottle 2, an injection pump 3, a steam Generator 5, flow meter 8 and intermediate piston container 4, measurement and control system, including thermocouple 22, injection well temperature, pressure, flow collector 10, production well differential pressure sensor 11, computer and its interface circuit 12, output analysis system , including a production fluid recovery device 13, an online gas analyzer 14 and an electronic balance 15, the analog body 9 is connected with the injection system, the measurement and control system and the output analysis system, and the analog body includes a main body 16 and a fixed cover 25 , the thermal insulation body 21 installed at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com