Production method of projector

A manufacturing method and projector technology, applied in cooling/ventilation/heating transformation, optics, instruments, etc., can solve problems such as complicated work, entry, and prolonged manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, an embodiment of the manufacturing method of the projector of the present invention will be described with reference to the drawings. Moreover, the projector manufactured by this manufacturing method is a device for projecting an image on a screen, and is constructed by assembling a plurality of units and components.

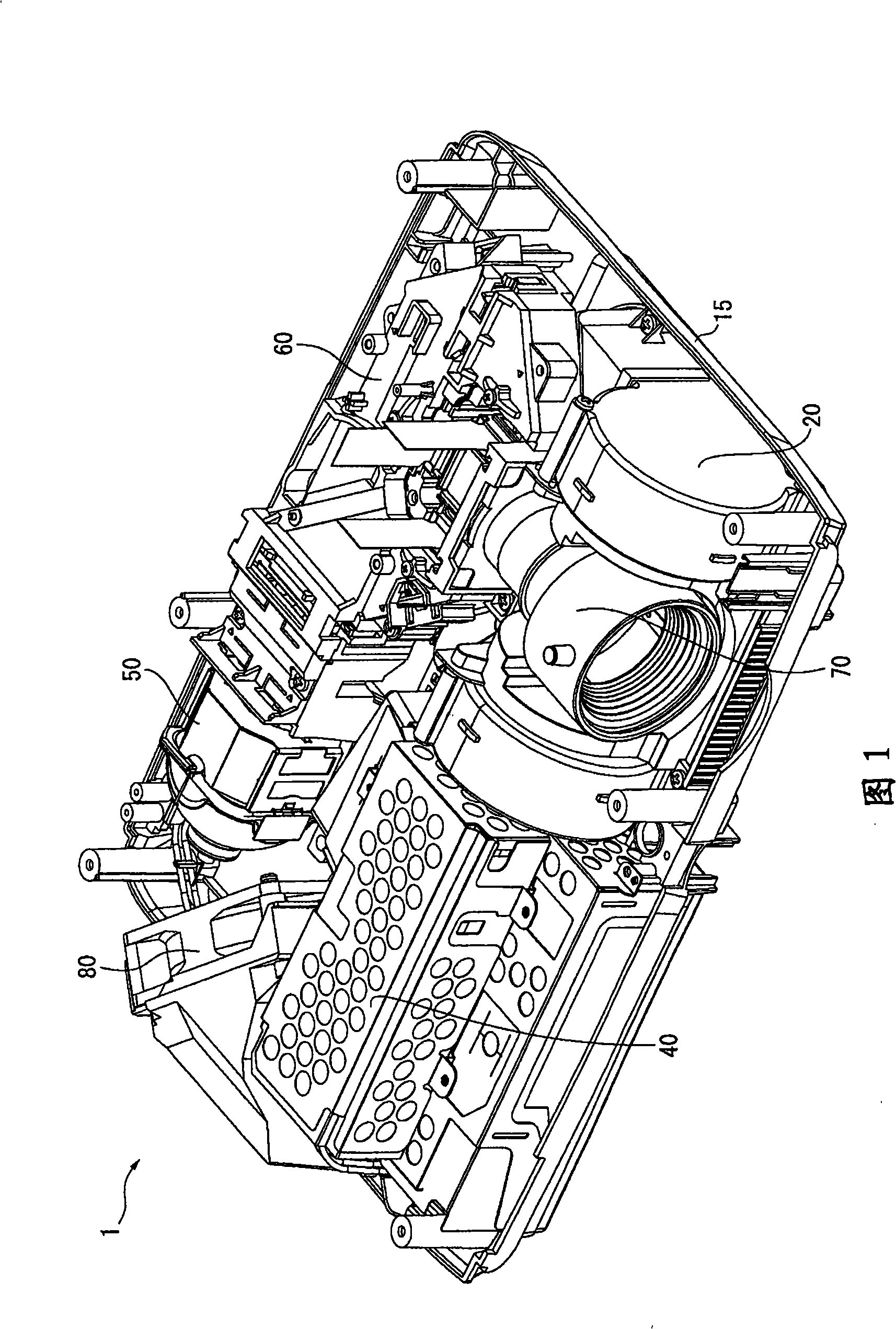

[0027] FIG. 1 is a perspective view of the inside of a projector manufactured by the manufacturing method of the present invention. Furthermore, in order to make it easier to see the units and components assembled inside the projector, this perspective view shows the inside in a state where the control device and the upper casing are removed.

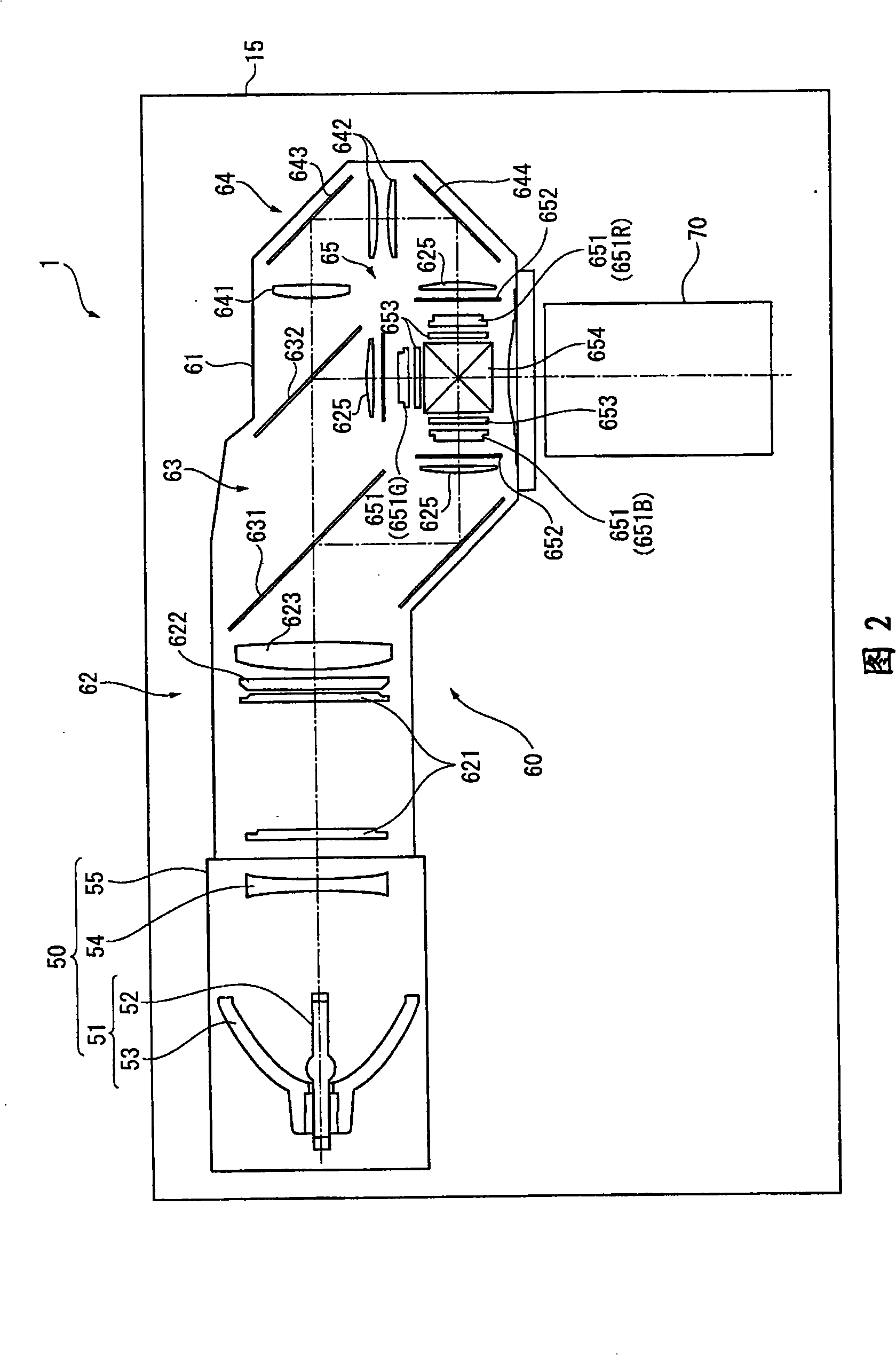

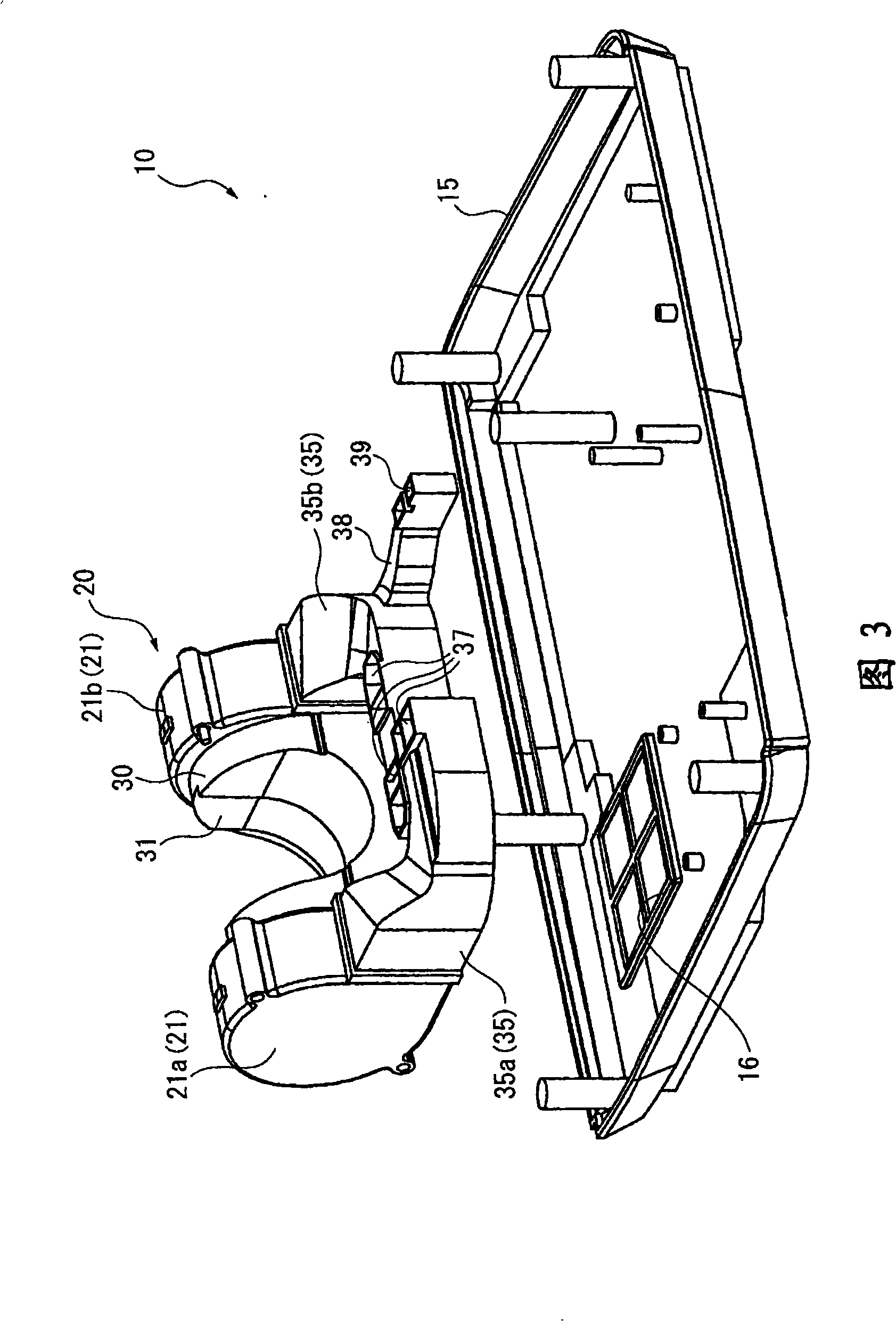

[0028] That is, the projector 1 is configured to roughly have: a lower housing 15 as an external housing; a cooling device 20 mounted on the lower housing 15; a power supply device 40 mounted on the lower housing 15; and a light source that emits light. The device 50; the optical unit 60, which optically p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com