Cleaner composition, article and method

A composition and cleaning agent technology, which can be used in the preparation of detergent compositions, detergent mixture compositions, aerosol detergent compositions, etc., and can solve the problem of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Cleanser compositions were formed according to Tables 1 and 2.

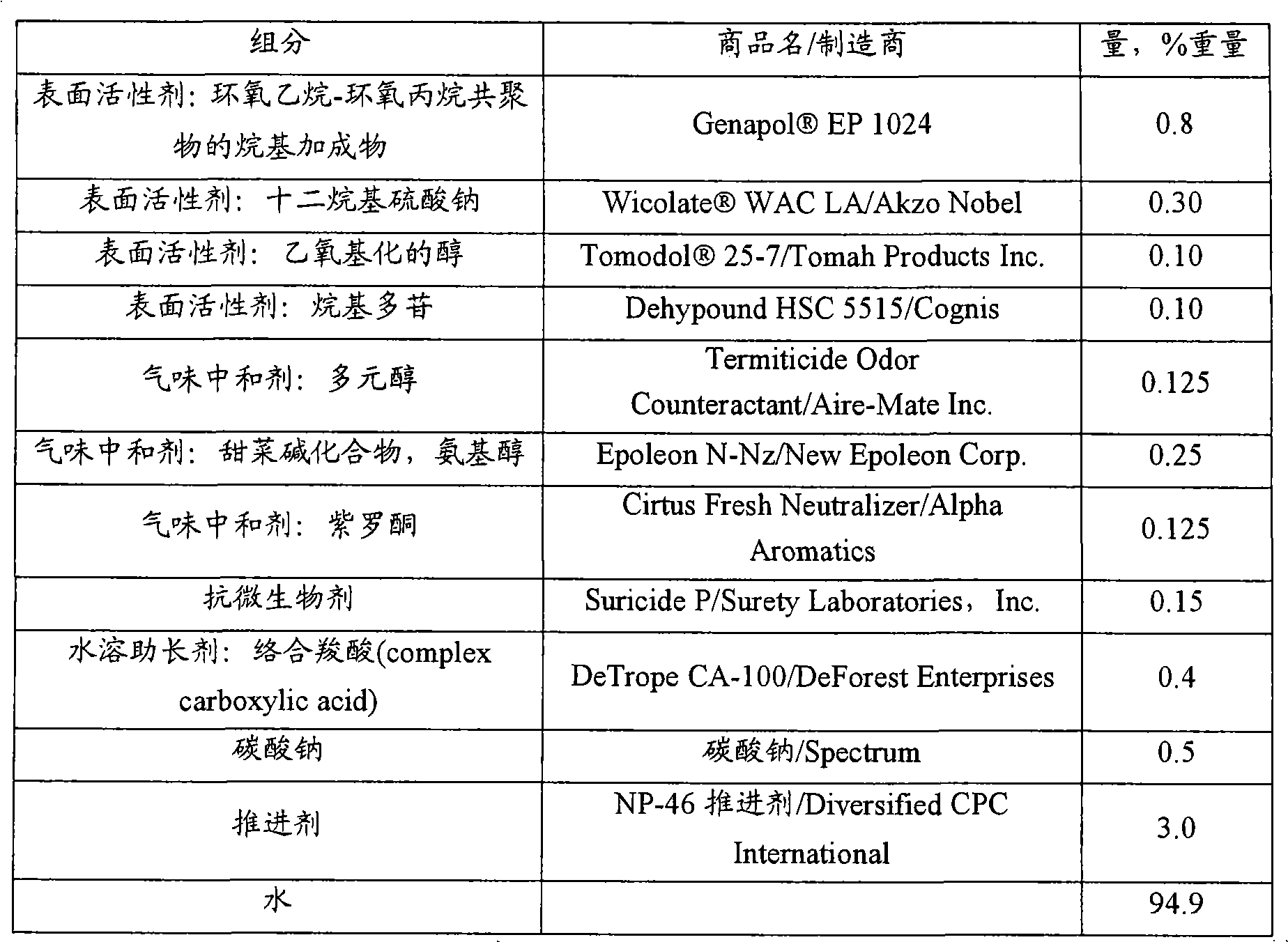

[0056] Table 1 - Formulation 1 of the present invention

[0057]

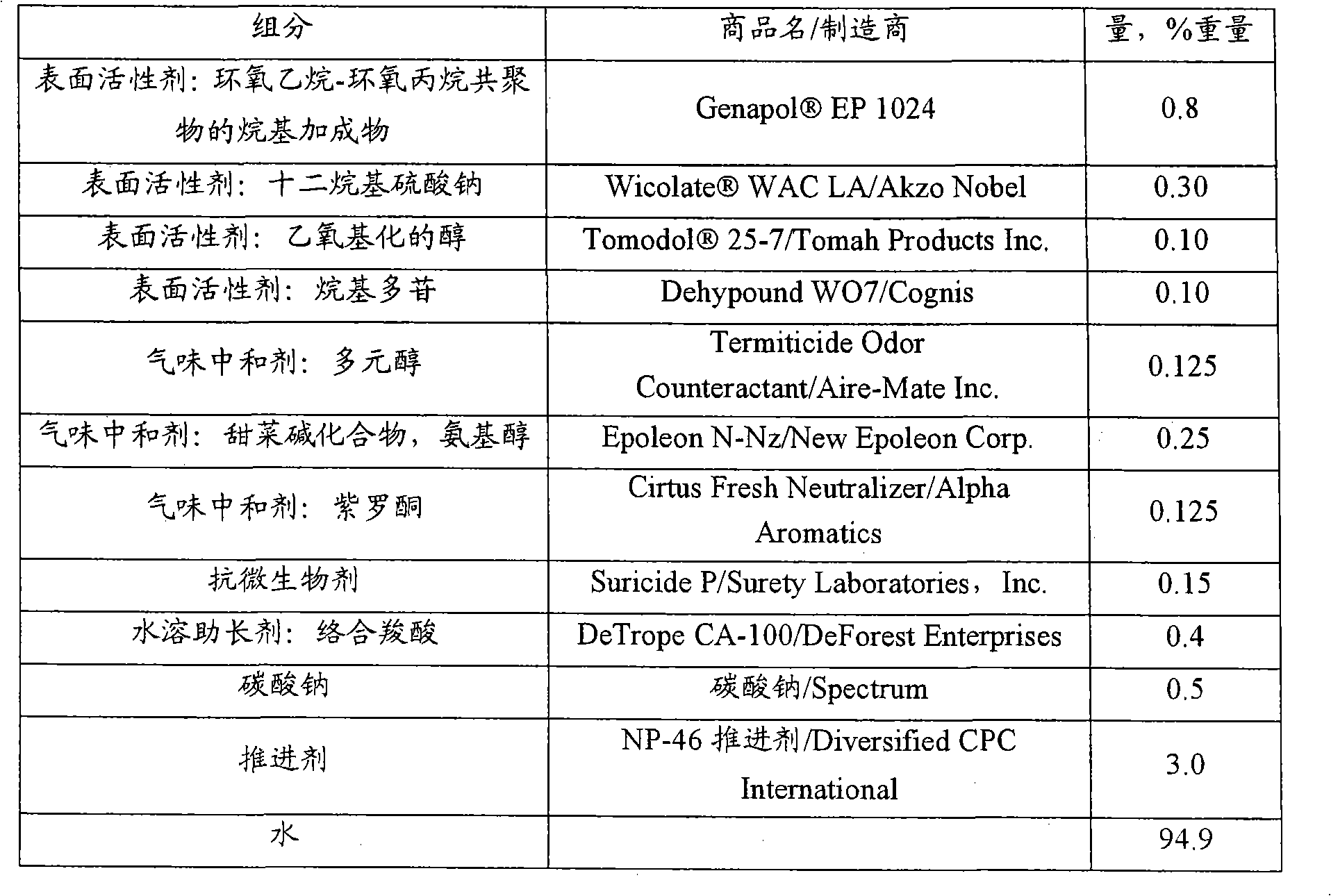

[0058] Table 2 - Formulation 2 of the present invention

[0059]

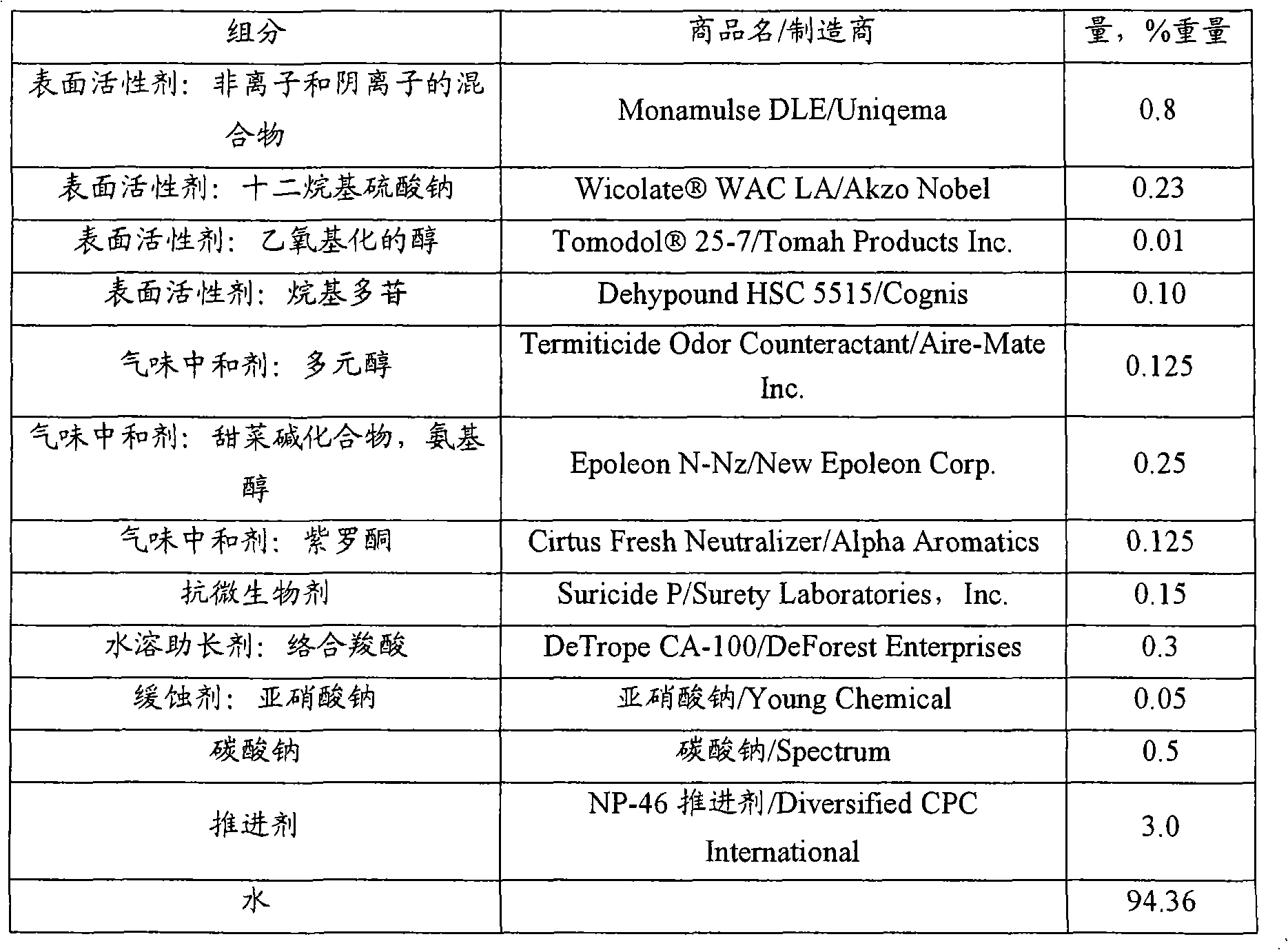

[0060] Table 3 - Control formulations

[0061]

[0062] To form the cleaner composition, water and a hydrotrope are mixed to form a first mixture. A surfactant is then added to the first mixture to form a second mixture. The remaining ingredients are then mixed in to form the final cleaner composition. The control formulations given in Table 3 were storage unstable at a pH of about 9.5 to about 11.5 when stored at about 25°C for 24 months.

Embodiment 2

[0063] Example 2 - cleaning-objective data

[0064] Cleaning test and deodorization test were carried out on the cleaning agent / odor neutralizer of the present invention of Example 1. Treat fabric (carpet and head liner) samples with soil. The fabric samples were cleaned by a trained technician (the technician was blinded to which detergent formulation was used) and the cleaning effectiveness was evaluated by a trained grader. Cleaning is done mechanically to eliminate variations in results due to washing. Subjective testing by trained graders to rate preferred cleaning power. The soils evaluated included coffee, used engine oil, mustard, ketchup, chocolate syrup, grape juice, soda (cola) and milk.

[0065] For the cleaning test, it is measured objectively by diffuse reflectance using a colorimeter. This is an industry standard tester. Stain removal was determined by the change in color of the fabric due to cleaning. For each stain, the overall difference in color of the...

Embodiment 3

[0077] Example 3 - Cleaning-subjective data-upholstery

[0078] Laboratory testing is based on the AS-345p carpet cleaning method and is subjective and double-blind. ANOVA was performed on the results (P is the value of the confidence limit for determining the occurrence of a chance event - the statistical analysis has a significance level of 95% with a p-value of 0.05 or less). MSE (analysis of assay systems based on ANOVA analysis gauge R&R (repeatability and reproducibility)) determined the number of distinct categories to be 6, acceptable for the 7-point Likert scale used.

[0079] Objective colorimeter testing was unsuccessful on upholstery due to the loose weave of the fabric. The background behind the fabric affects the colorimeter, resulting in a large standard deviation of the measurement. Since the number of distinct species is 0 (see MSE Colorimeter / Upholstery), MSE indicates that the test method cannot distinguish between the samples.

[0080] Table 6 - Subjecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com