Plastic shell lithium ion battery and its making method

A technology of lithium-ion batteries and plastic casings, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve the problems of ion battery leakage, liquid leakage, unsatisfactory service life and safety performance, and achieve Enhance the sealing effect and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

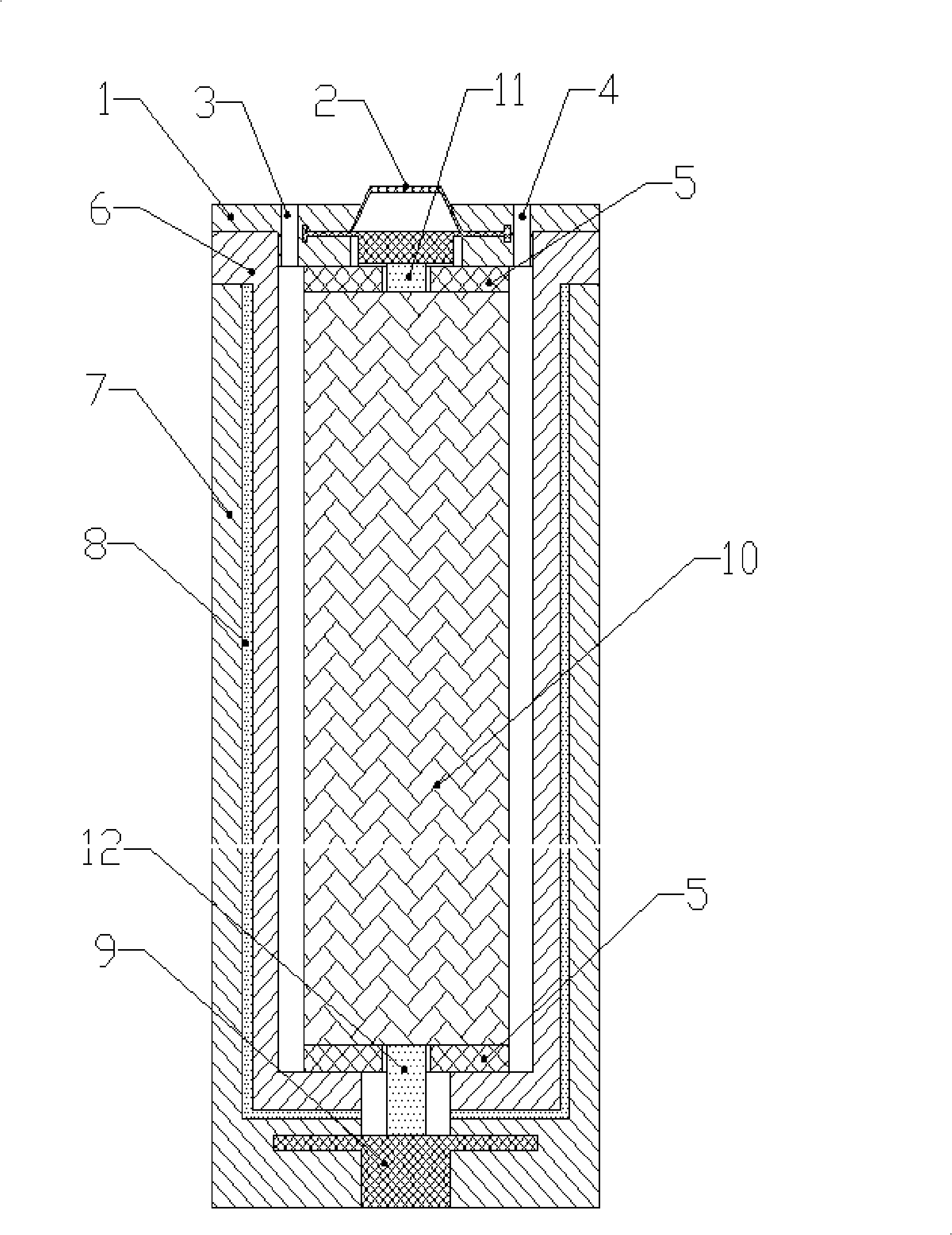

[0029] The preparation method of the plastic case battery case of the present invention comprises the following steps:

[0030] ① Prepare the battery core; prepare the metal isolation layer (8);

[0031] A corrosion-resistant layer (6) with full openings on the periphery, bottom and upper part is injection-molded from engineering plastics, and a through hole is provided at the bottom;

[0032] A protective layer (7) with full openings on the periphery, bottom and upper part is injection-molded from engineering plastic material, and a metal insert as a negative pole (9) is inlaid at the bottom;

[0033] An upper cover plate with a positive pole (2), a liquid injection hole (3) and a vacuum hole (4) is injection-molded from engineering plastics;

[0034] ② Put the battery core (10) into the corrosion-resistant layer (6), and the negative electrode tab (12) of the battery core passes through the through hole at the bottom of the corrosion-resistant layer (6);

[0035] ③ Wrap the ...

Embodiment 1

[0058] Embodiment 1 Preparation of plastic case battery of the present invention

[0059] Taking the national standard battery size of 18650 as an example, the specific preparation method of the plastic case battery of the present invention is as follows:

[0060] 1. Injection molded from ABS material into a cylindrical shell with a thickness of 1mm, full opening at the top, and a through hole with a diameter of 9-10mm at the bottom, and a nickel metal insert with a diameter of 9-10mm is embedded in the shell, and the nickel metal insert and the shell The bottom through hole is closely matched; the outer diameter is Ф18mm and the height is 62.5mm.

[0061] Injection molded from PP material into a cylindrical inner shell with a thickness of 0.5mm, an upper opening with a 0.5mm outer edge, and a 45mm diameter through hole at the bottom; the outer diameter is φ17mm or φ25mm, and the height is 62.5mm.

[0062] The upper cover plate with positive pole, liquid injection hole and va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com