Stretcher for sheet-like substance

A sheet-like and stretching machine technology, applied in the field of sheet-like devices, can solve the problems of uneven radiation energy, inefficient transmission of radiation energy, uneven stretching performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

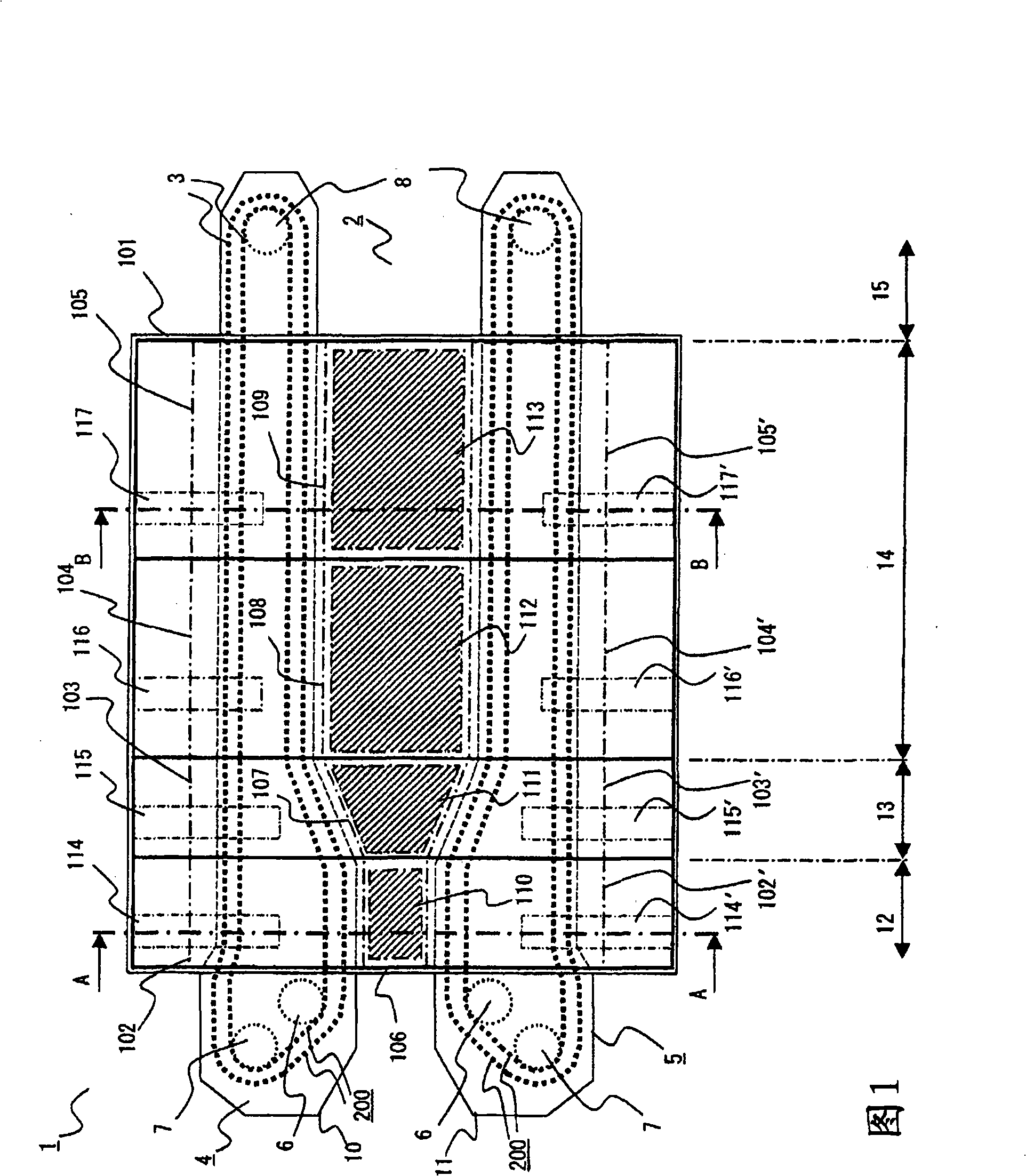

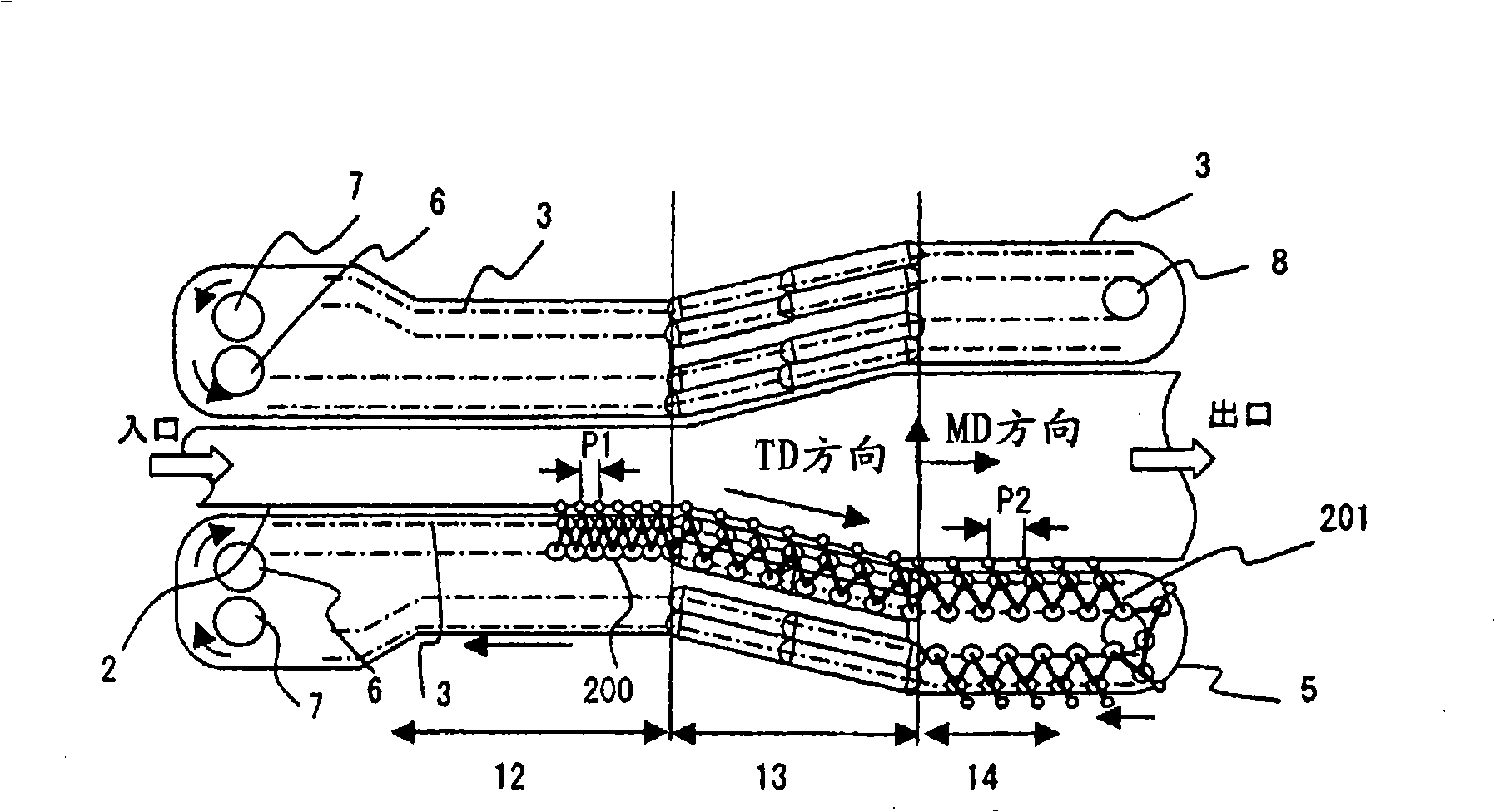

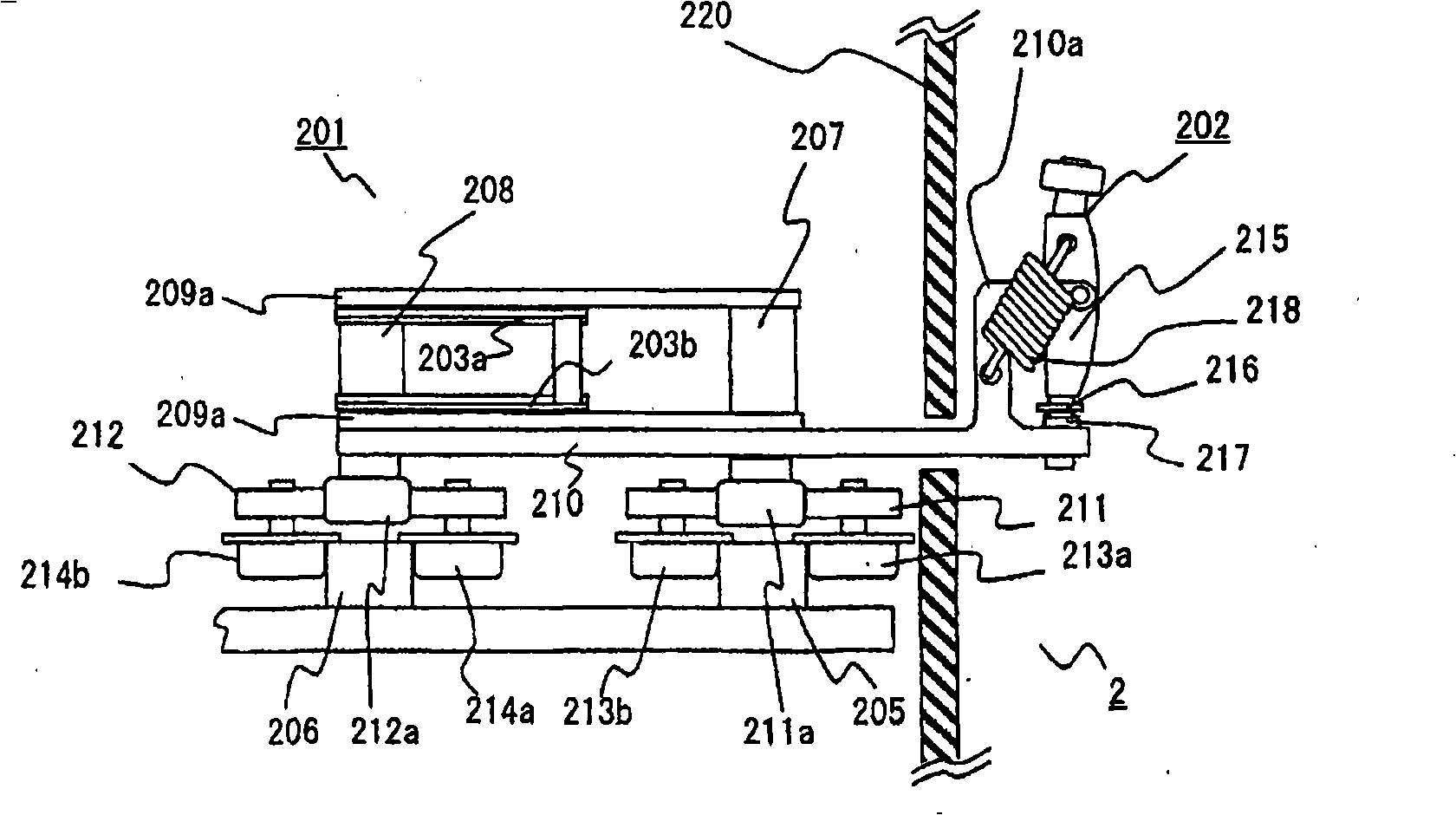

[0033] Using Figure 1 to Figure 10 An example of a stretching machine for a sheet of the present invention will be described.

[0034] First, using Figure 1 to Figure 5 The configuration of the above-mentioned embodiment will be briefly described. Fig. 1 is a plan view schematically illustrating the construction of a stretching machine for sheet-like objects according to the present invention. figure 2 It is a schematic schematic diagram showing the structure of the link device of the sheet stretching machine shown in FIG. 1 .

[0035] First, using Figure 1 and figure 2 The configuration of the sheet stretching machine 1 and the link device used in the stretching machine according to the embodiment of the present invention will be described.

[0036] The sheet stretching machine 1 shown in FIG. 1 has a conveying space 2, and the conveying space 2 conveys a sheet formed of a thermoplastic resin or the like extending toward the center; The two sides of the conveying direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com