Non-oriented electrical steel head and tail flash welding technique

A technology of oriented electrical steel and process method, which is applied in the field of head-to-tail flash welding of non-oriented electrical steel, can solve the problems of easy-to-break electrical steel welds, high maintenance technical requirements, and deteriorated weld performance, etc., to achieve good plasticity and toughness , avoiding joint breakage and improving the quality of weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

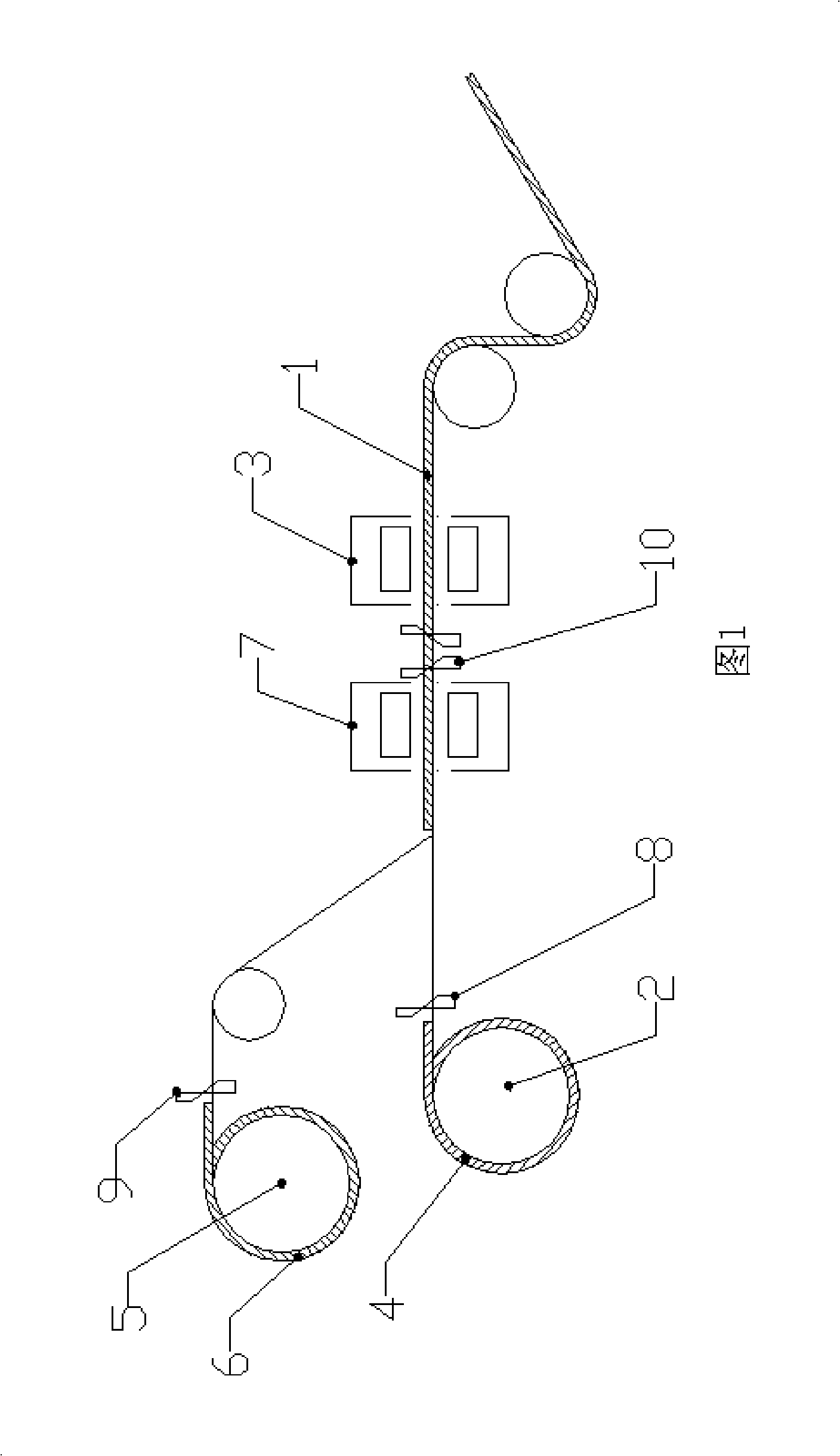

[0032]Example 1: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 , the low-carbon steel series transition steel 4 of the DX series with the same thickness and width is placed on the second roll-up position 2, and the low-carbon steel series transition steel 4 can reciprocate forward and backward at the second roll-up position 2 Return materials. After the tail of the pre-coiled non-oriented electrical steel 1 that has entered the acid tank and the head of the low-carbon steel series transition steel 4 of the DX series complete the first flash welding, the low-carbon steel series transition steel 4 at the second winding position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding machine, the shear knife 9 cuts the DX seri...

Embodiment 2

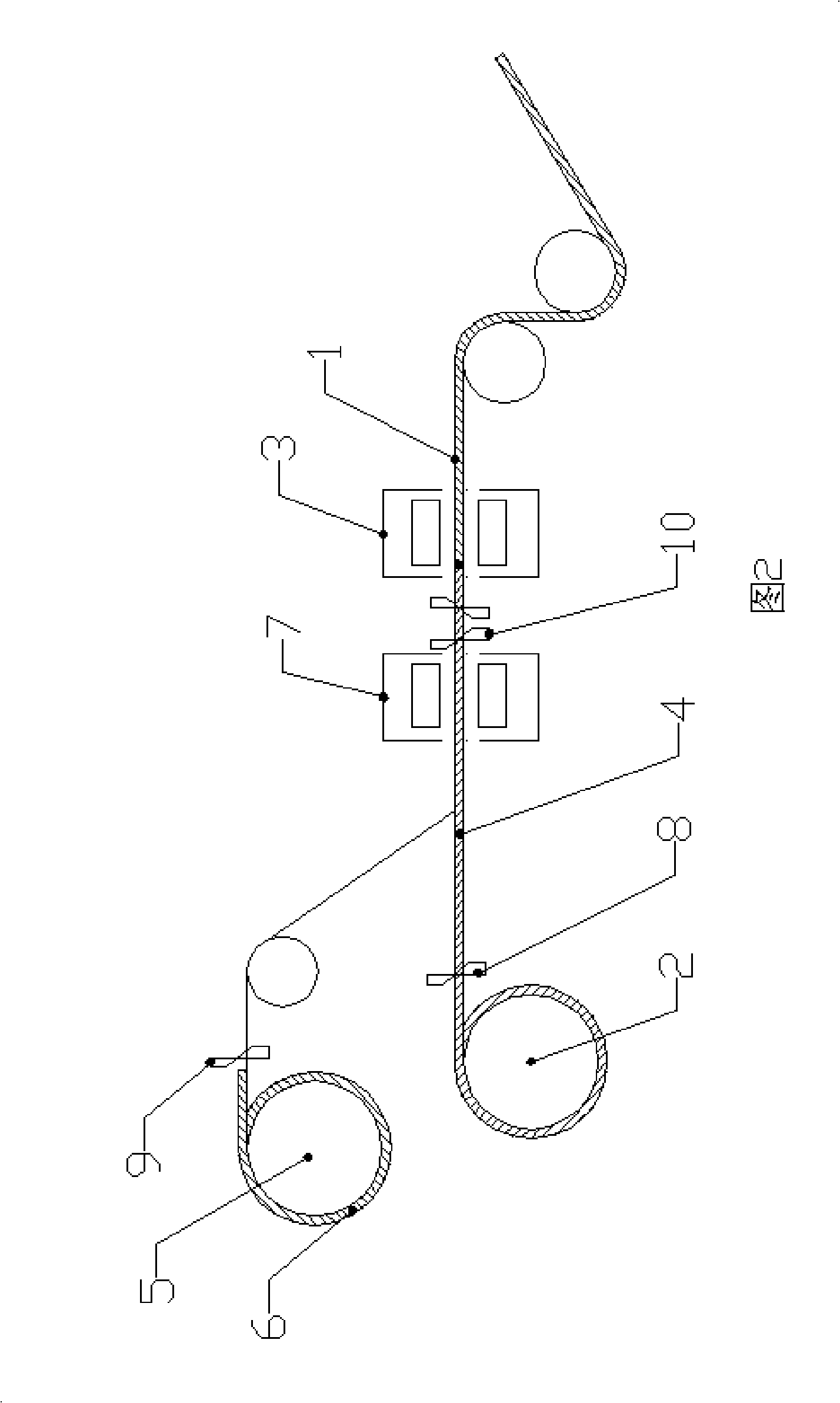

[0033] Example 2: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 , the low-carbon steel series transition steel material 4 of the IF series with the same thickness and the same width is placed on the second roll-up position 2, and the low-carbon steel series transition steel material 4 can reciprocate forward and backward at the second roll-up position 2 Return materials. After the first flash welding is completed between the tail of the pre-rolled non-oriented electrical steel 1 that has entered the acid tank and the head of the IF series low-carbon steel series transition steel 4, the low-carbon steel series transition steel 4 at the second roll-up position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding machine, t...

Embodiment 3

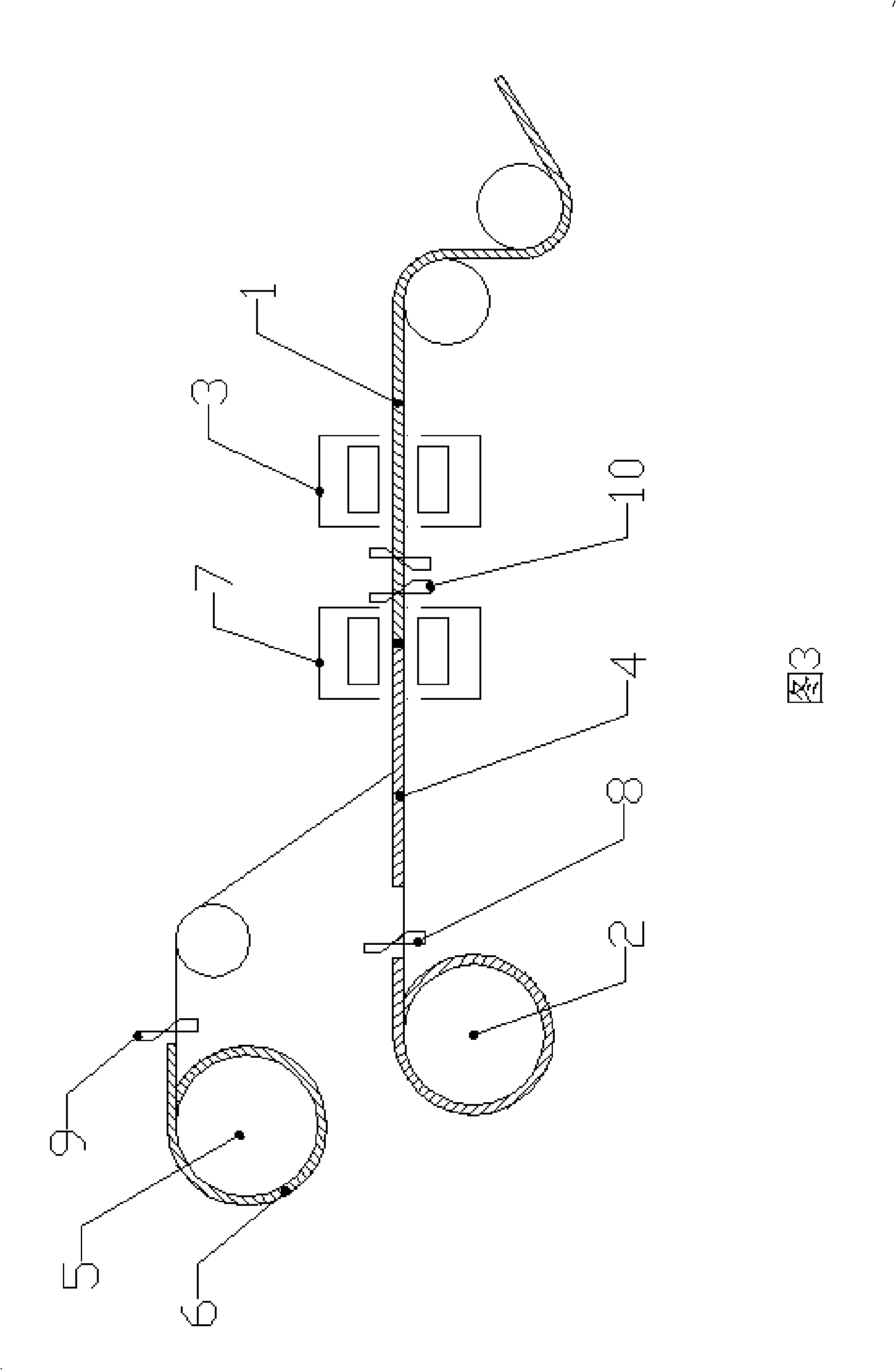

[0034] Example 3: In the combined cold-rolling and acid-rolling unit, the current coil of non-oriented electrical steel 1 enters the acid tank, and after the tail leaves the first coiling position 5, the rear coil of non-oriented electrical steel 6 is placed at the first coiling position 5 The low-carbon steel series transition steel material 4 of the St series with the same thickness and the same width is placed on the second roll-up position 2, and the low-carbon steel series transition steel material 4 can be reciprocally fed forward and back at the second roll-up position 2 Return materials. After the first flash welding is completed between the tail of the pre-rolled non-oriented electrical steel 1 that has entered the acid tank and the head of the low-carbon steel series transition steel 4 of the St series, the low-carbon steel series transition steel 4 at the second winding position 2 Drive the welded seam back to the electrode 7 side of the movable end of the welding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com