Method of mounting elements inside a wind generator tower

A technology for installing components for wind power generators, applied in the field of installing components inside metal towers, can solve the problems of increasing tower wall thickness and reducing tower wall fatigue strength, and achieve the effects of reducing thickness, simplifying manufacturing and assembly processes, and avoiding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

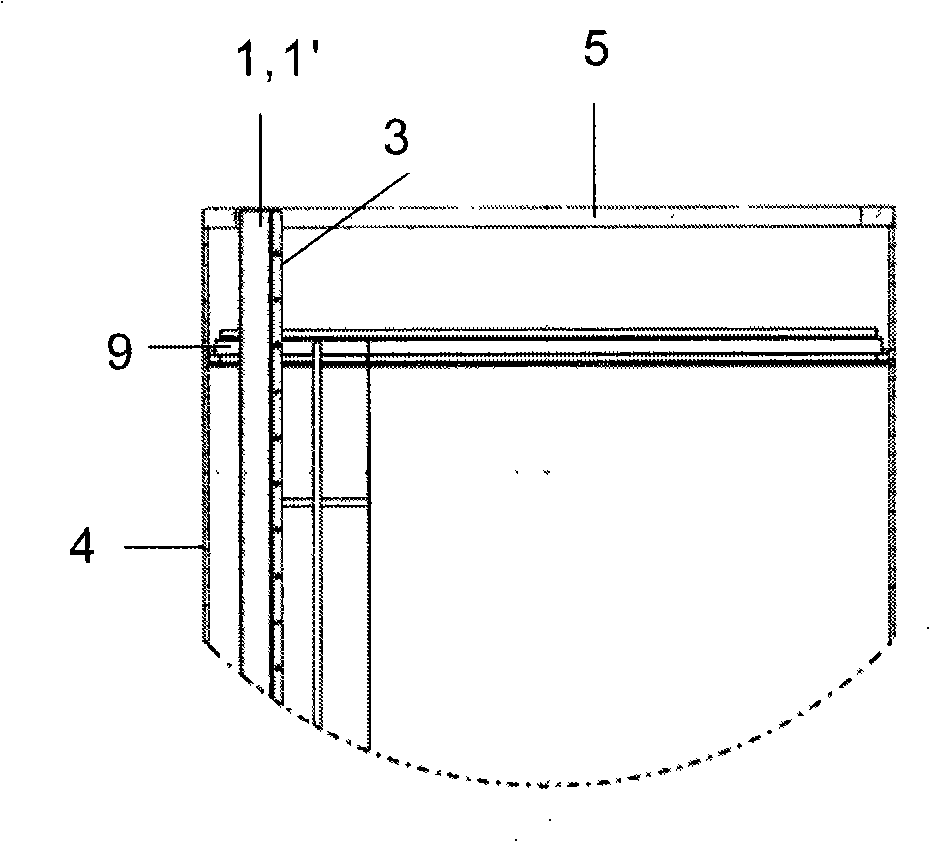

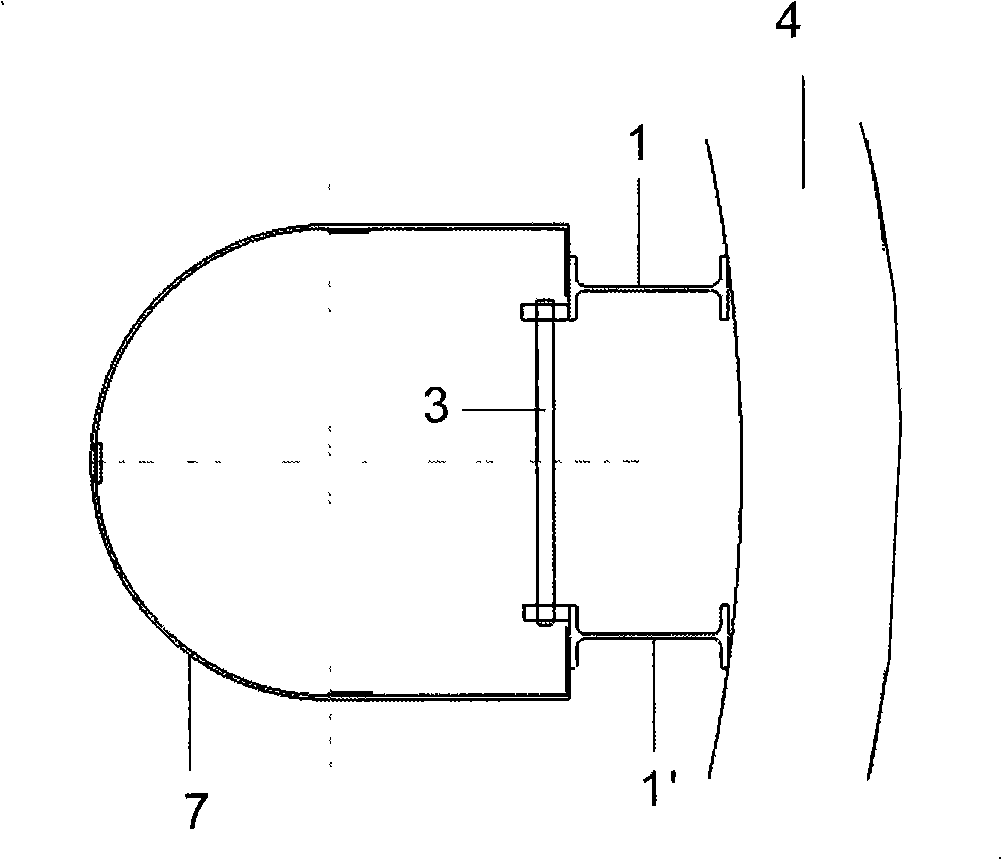

[0017] Metal wind turbine towers are formed by several segments 4 ranging in length from 10 m to 30 m, which are cylindrical bodies or tube cones (troncocónica) with an upper flange 5 and a lower flange 6 for contact with Other segment connections.

[0018] According to a first embodiment of the invention, the ladder 3 is not fixed directly to the section 4 of the tower, but to the two beams 1 and 1'.

[0019] Beams 1 and 1', preferably of double T-profile, are fixed to the upper flange 5 and the lower flange 6 of the section 4 of the tower in a manner parallel to the walls. They are fixed rigidly, for example by welding or bolts, to the upper flange 5 and horizontally to the lower flange 6 in a manner allowing longitudinal displacement.

[0020] This way of fixing the beams 1 and 1' allows for the bending of the section 4 caused by the working loads acting on the tower and likewise allows for expansion and contraction with temperature changes, whereas the aforementioned beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com