Methods of Strengthening Masonry Walls with Steel Structures

A technology for masonry walls and steel structures, applied in building components, building structures, building maintenance, etc. problems, to achieve the effect of low cost, shorten the reinforcement period, and improve the shear bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments.

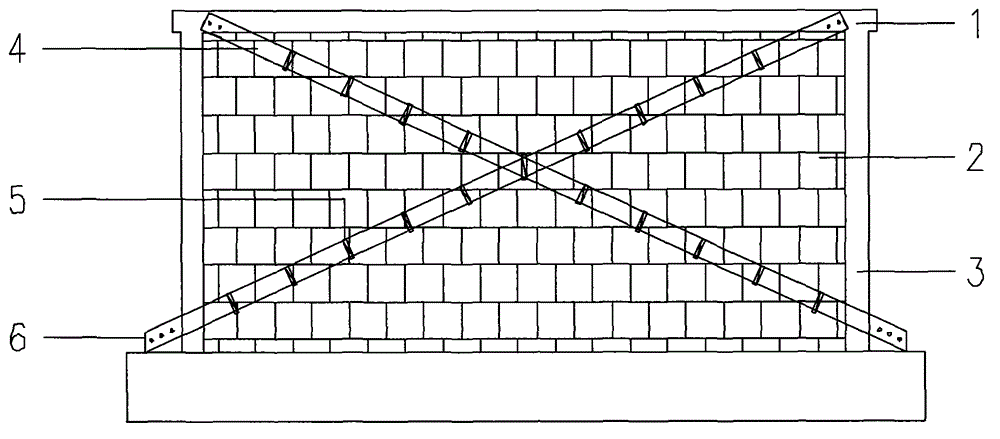

[0027] As shown in the figure, when the present invention reinforces the wall, it includes the following steps:

[0028] 1) Drill two holes at both ends of the ring beam 1, and use two 8.8-grade M18 high-strength bolts to pass through, and connect the two reinforced steel plates 4 on both sides of the ordinary brick wall 2 to the ring beam 1 at the upper end reliably;

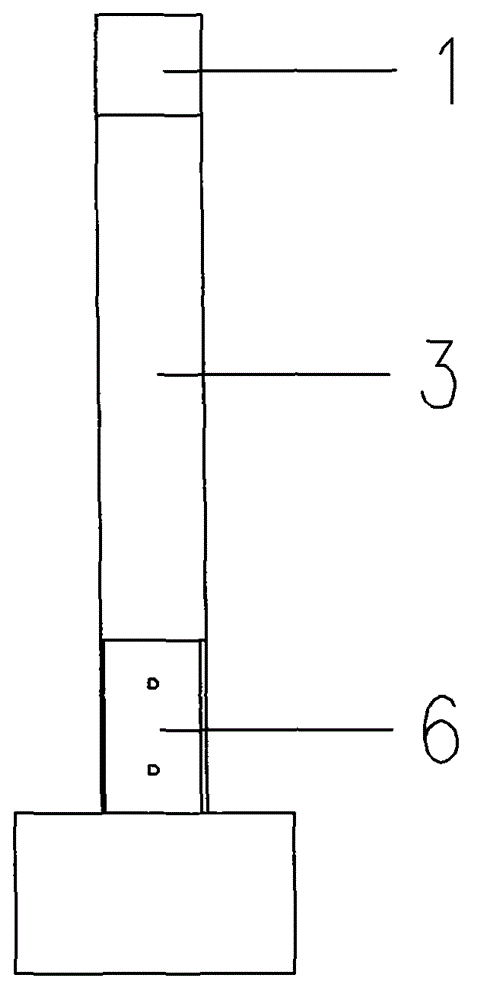

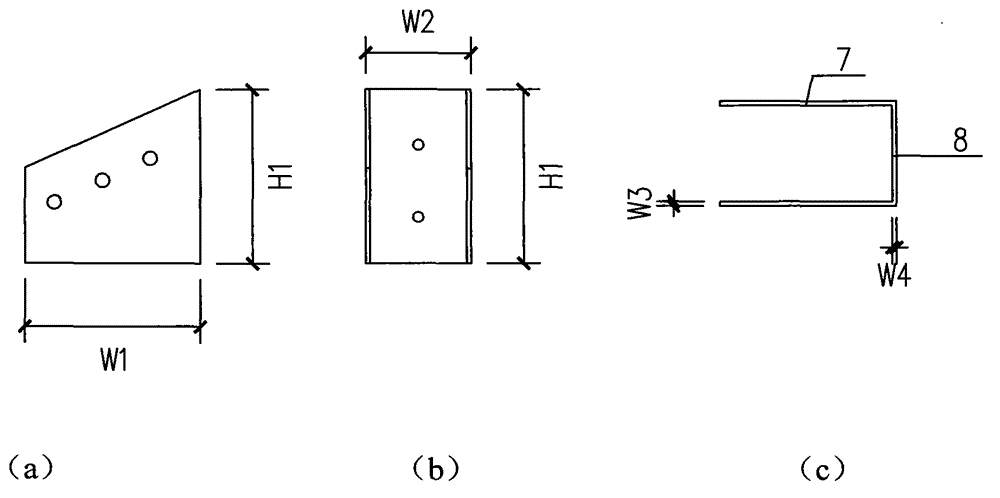

[0029] 2) Two M12 chemical bolts are used on both sides of the bottom to connect the connector 6 to the structural column 3 through its web 8;

[0030] 3) Connect the lower end of the reinforced steel plate 4 to the flange 7 of the connector 6 through three 8.8-grade M16 high-strength bolts, and the connection method of the reinforced steel plate on the back is the same;

[0031] 4) Drill holes on the reinforced masonry wall 2, insert 19 steel buckles 5, bend and weld to form clips, and fasten the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com