Super or super supercritical coal fired power generation heat system improvement method

A technology of thermal system and improvement measures, applied in the direction of non-flammable liquid/gas transportation, preheating, combustion methods, etc., can solve problems such as increasing flow resistance and increasing plant power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

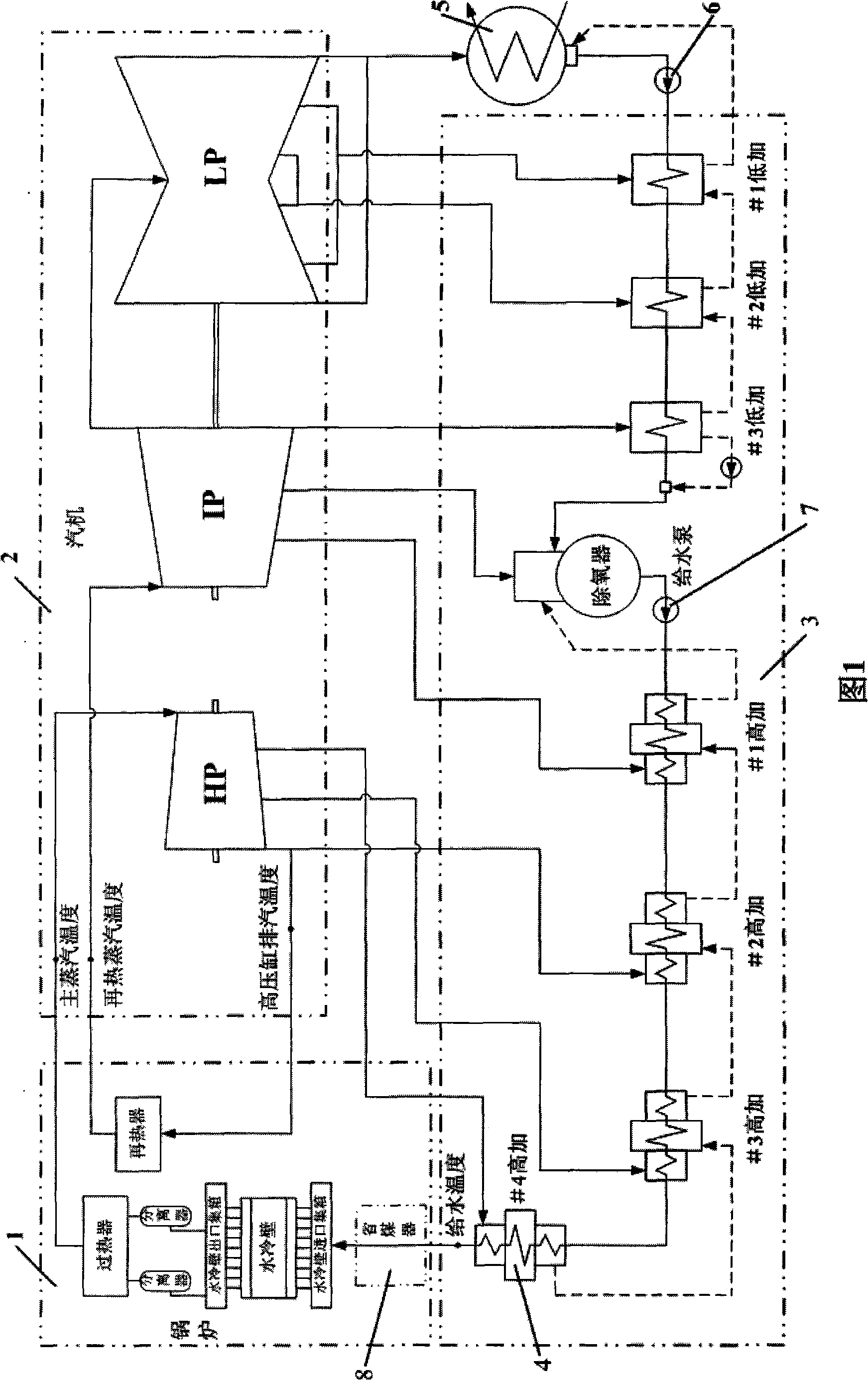

[0013] Description will be made below in conjunction with the accompanying drawings. The invention provides an improvement measure for an ultra- or ultra-supercritical coal-fired power generation thermal system, and relates to an economizer-free ultra- or ultra-supercritical boiler and its power plant thermal system and parameter configuration. In FIG. 1 , the system includes a coal-fired boiler 1 , a steam turbine 2 , a feedwater recuperation heater system 3 , a condenser 5 , a condensate pump 6 and a feedwater pump 7 . The economizer 8 (the middle position on the left in the figure) necessary for the conventional coal-fired unit boiler is removed, and a first-stage high-pressure feed water recuperation heater 4 is added at this position (#4 high addition in Fig. 1), because the economizer 8 is removed. The temperature of the feed water entering the water wall after the coal burner will decrease, which will affect the average temperature of heat absorption and the heat load r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com