Connector for close type compressor and operating fluid inhalation device using same

A closed compressor and working fluid technology, which is applied in the direction of machines/engines, liquid variable displacement machines, mechanical equipment, etc., can solve the problems of slender closed container 8 and reduce the fluidity of working fluid, and achieve the goal of improving fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. In the following description and drawings, the same or similar components are denoted by the same reference numerals, and thus repeated descriptions of the same or similar components will be omitted.

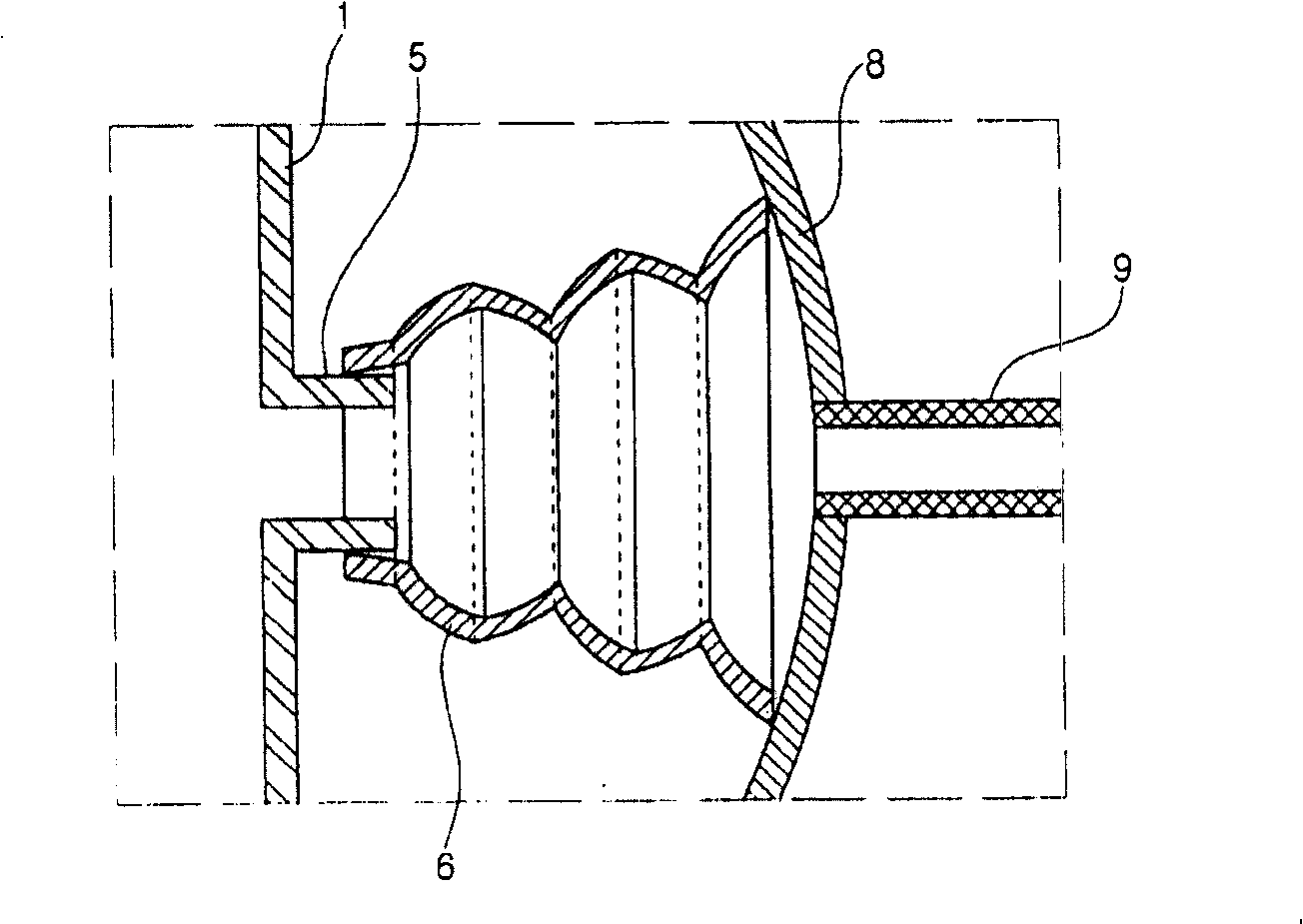

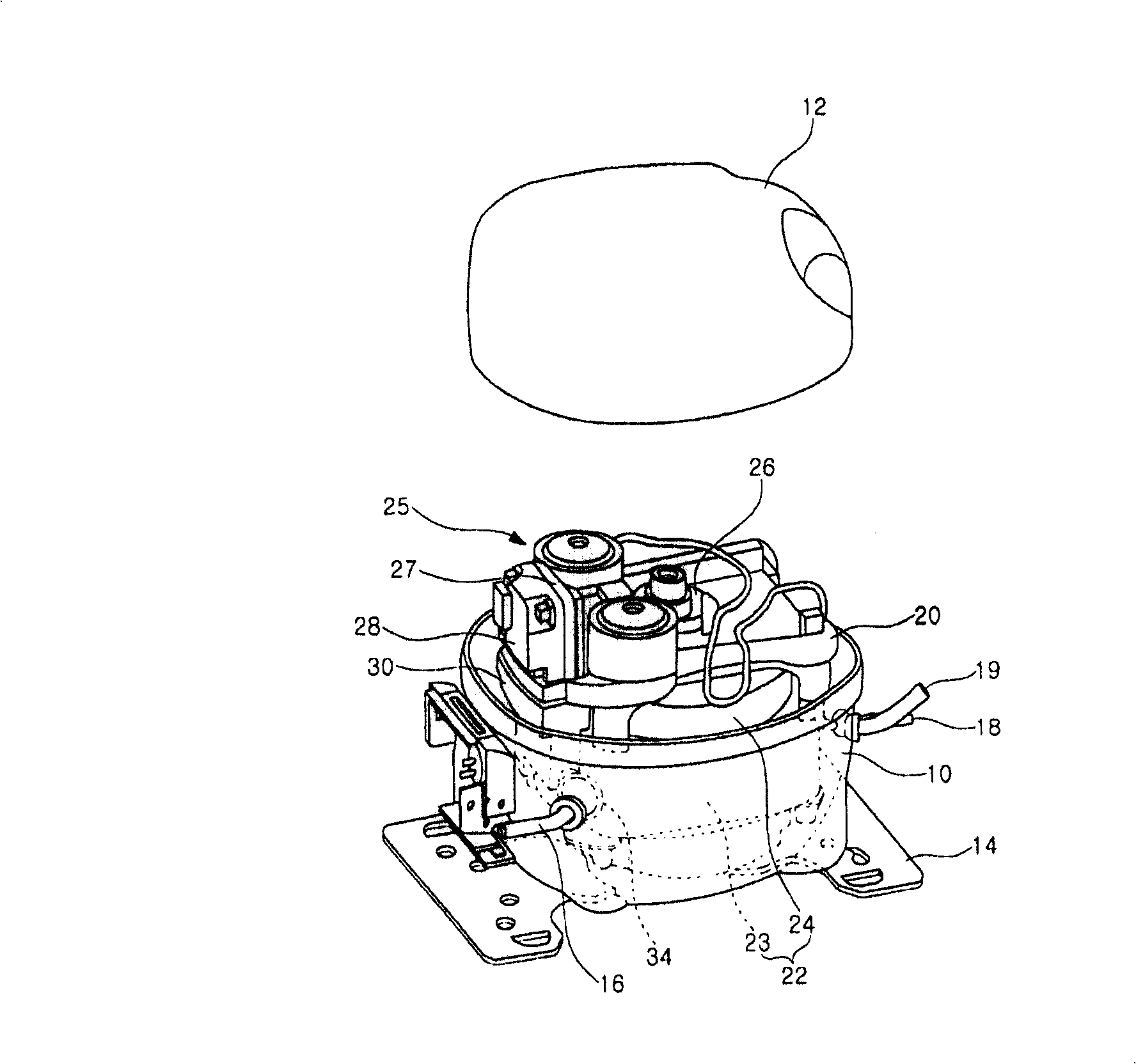

[0030] image 3 is an exploded perspective view of a hermetic compressor using a working fluid suction device according to a preferred embodiment of the present invention, FIG. 4 is a partial sectional view of the configuration of an embodiment of the present invention, and FIG. 5 is a perspective view Fig. 1 shows the intake muffler and connectors constituting this embodiment of the present invention.

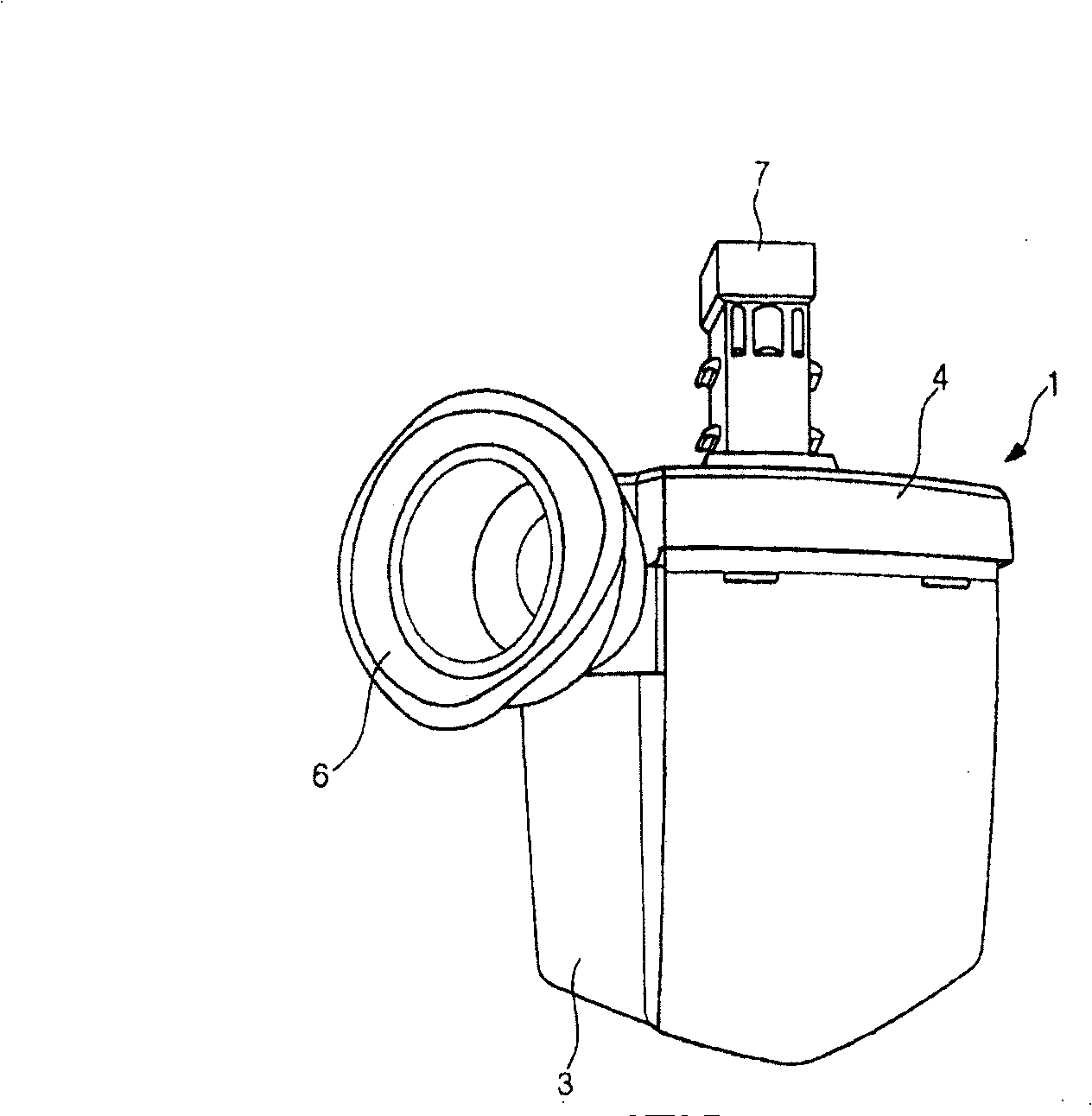

[0031] Referring to these drawings, the appearance of the compressor is composed of a lower container 10 and an upper container 12 . The lower container 10 and the upper container 12 are engaged with each other to form a closed space therebetween. Each of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com