Water streak roller and method of manufacture

A technology of water lines and roller shafts, which is applied in the production of water line paper rolls and its manufacturing field. It can solve the problems of complex manufacturing process, unsmooth lines, and easy breakage at water lines, etc., to achieve a round and smooth appearance, vertical and horizontal Straight lines, smooth and natural water lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

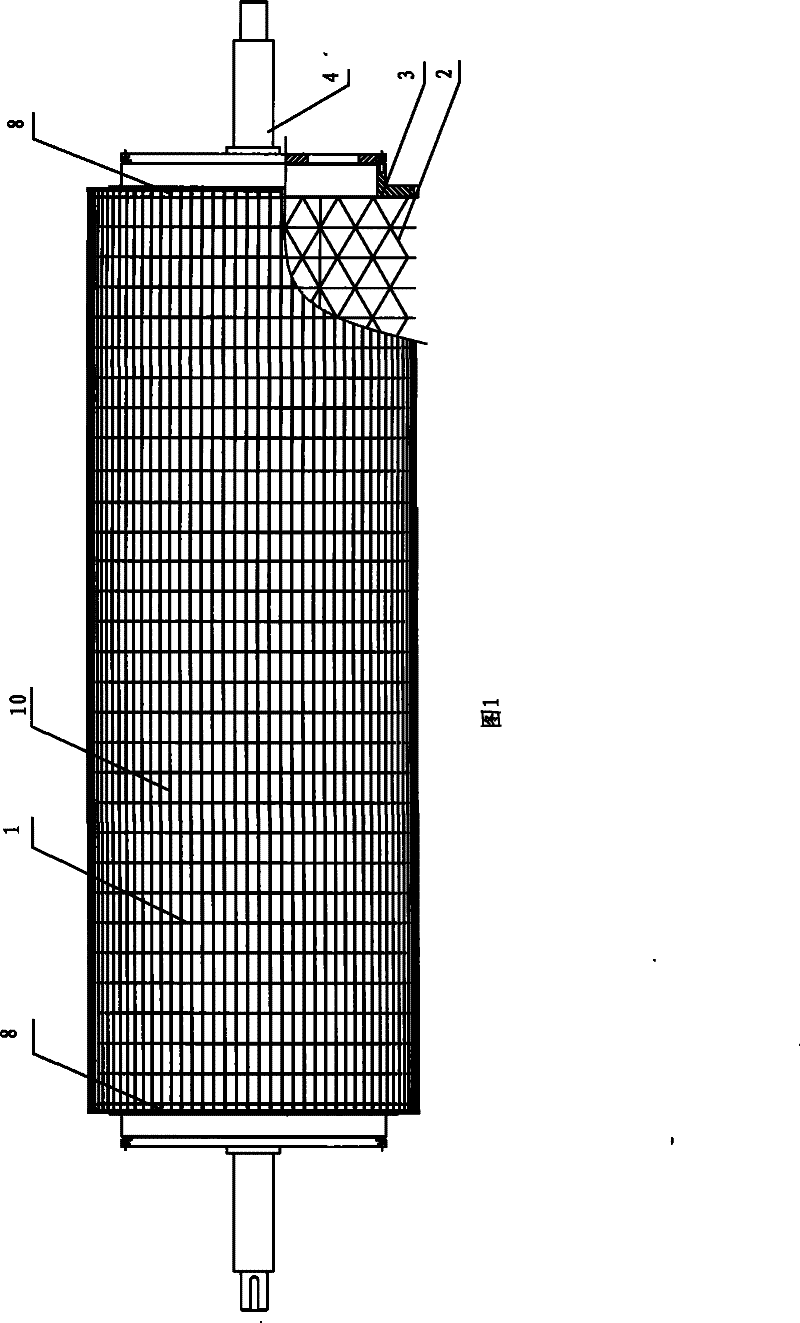

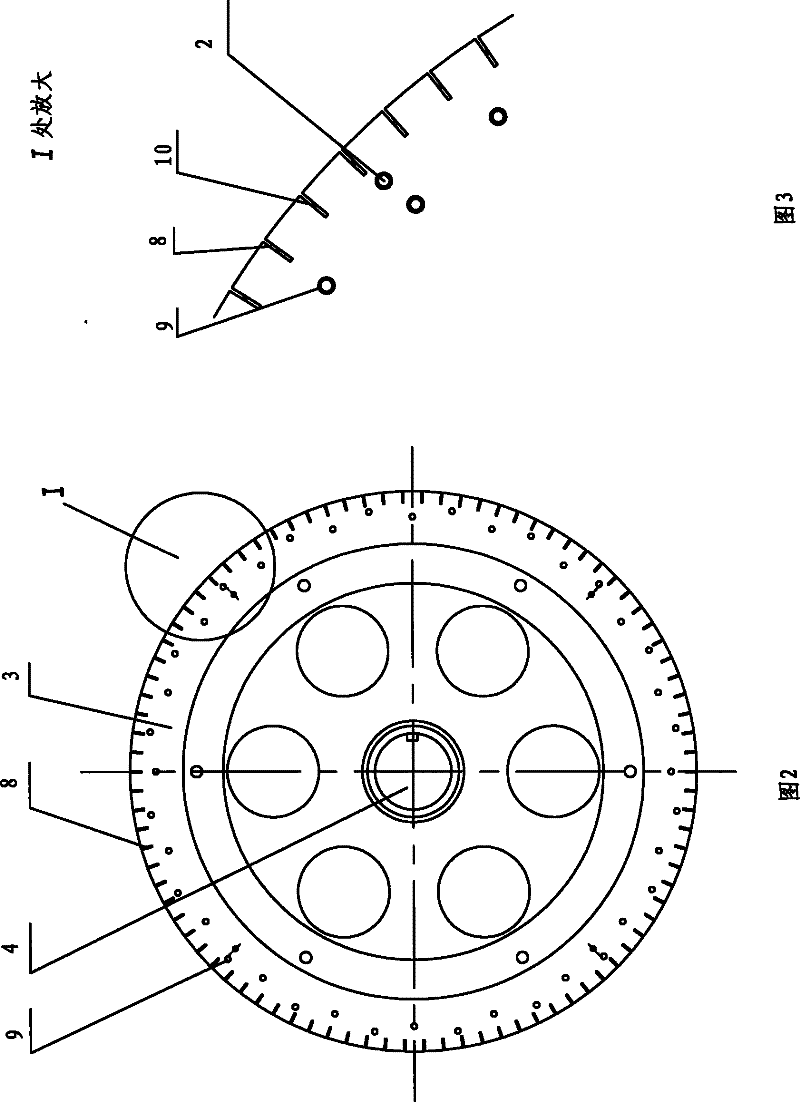

[0025] exist figure 1 Among them, a watermark roller consists of several ring-shaped skeleton sheets 1, a number of fixed drawing wires that connect and fix the ring-shaped skeleton sheets 1 into a cylindrical hollow roller, and additionally installed on the ring-shaped skeleton sheets at both ends of the roller. The roller end disk 3 and the roller shaft 4 connected with the roller end disk 3 are composed.

[0026] The roller shaft at one end of the watermark roller 4 is a roller shaft that plays a supporting and transmission role, so the end roller shaft is milled with a drive keyway; the other end is a roller shaft that plays a connecting support role, so this end roller shaft is an optical axis.

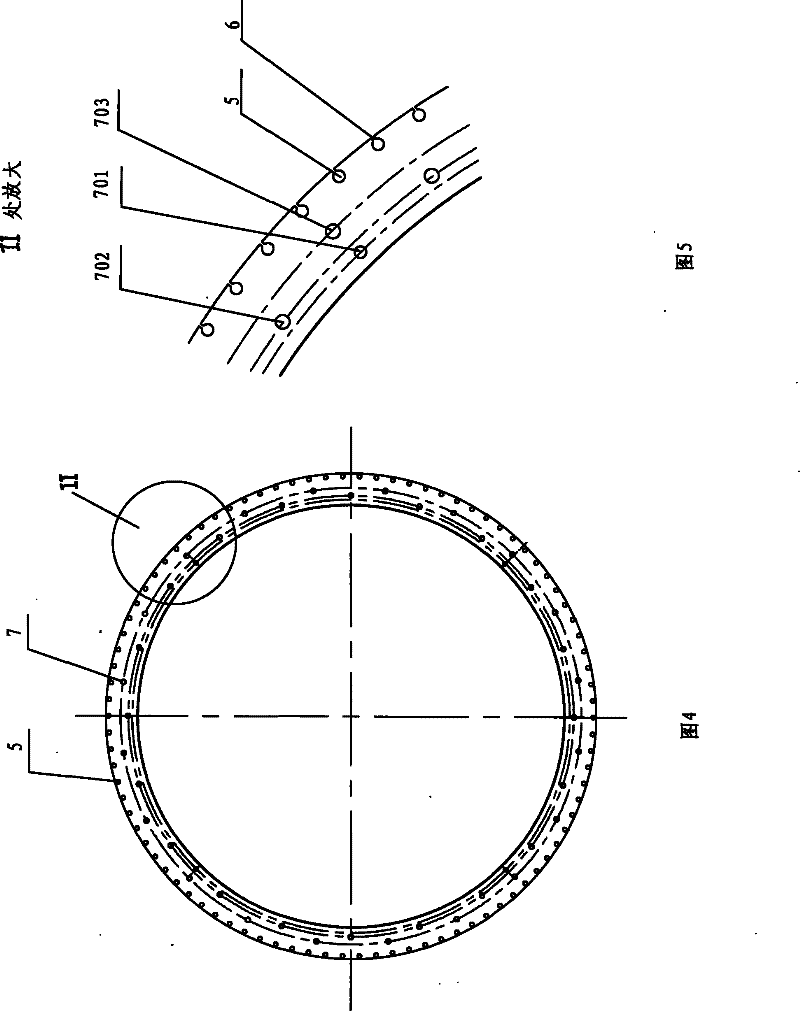

[0027]exist Figure 4 , Figure 5 Among them, a plurality of through holes 5 are evenly opened on the radial surface of the same radius inside the circumference of the annular skeleton sheet 1, and communicating through holes are respectively opened in the radial direction corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com