Method and device for synchronously treating steel pickling waste water and coking waste water

A technology for iron and steel pickling and coking wastewater, applied in chemical instruments and methods, metallurgical wastewater treatment, sustainable biological treatment, etc., can solve the problems of high treatment costs, low treatment efficiency of internal pickling wastewater and coking wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

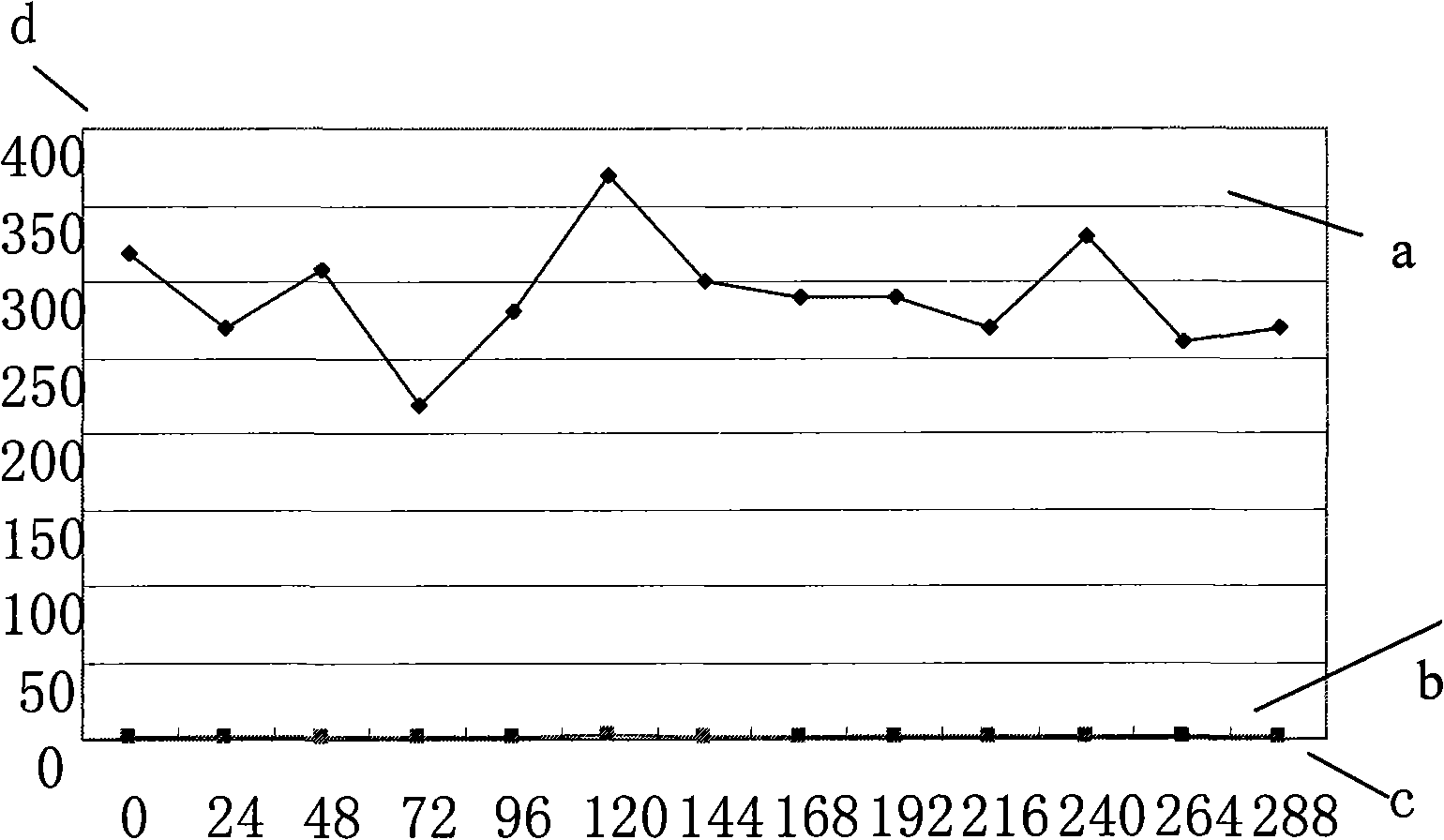

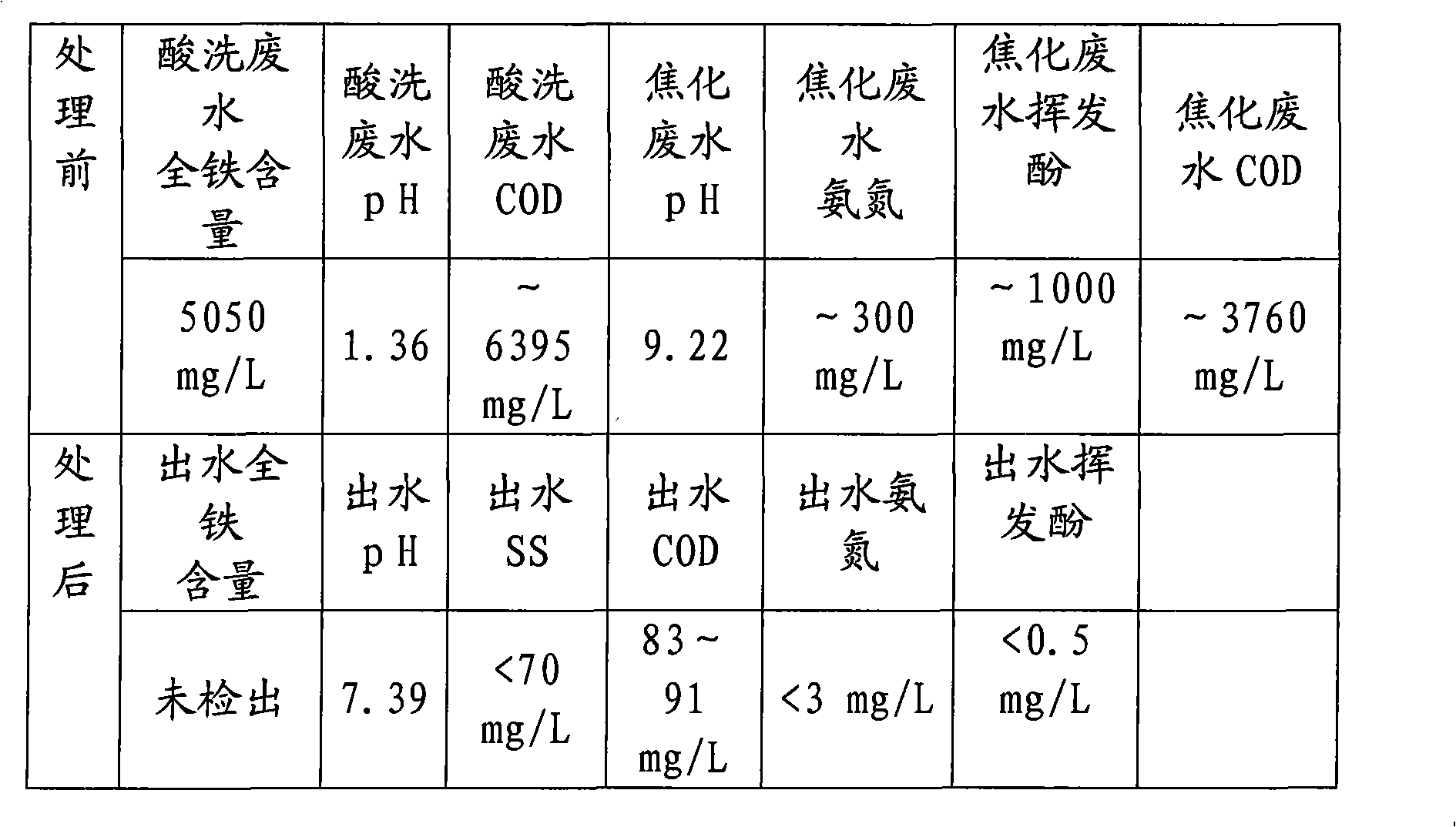

[0144] as attached figure 1 As shown, the pickling wastewater and coking wastewater were first mixed through the storage tank 1, and the pickling wastewater and coking wastewater were mixed in the storage tank 1 at a ratio of 1:80. The water quality analysis results before and after the mixing of the pickling wastewater and coking wastewater are shown in Table 1. Show

[0145] Table 1

[0146] Coking wastewater

Pickling wastewater

after mixing

pH

9.22

1.36

8.75

Volume ratio of sediment after 30min %

30

Total iron mg / l

5050mg / l

not detected

CODcrmg / l

3760.8

6395.7

3603.2

[0147] After mixing and sedimentation in the storage tank 1, take the supernatant, first pass through the air flotation device, pre-treat to remove oil, suspended solids and slag, and then pass through the primary aeration tank 2, primary sedimentation tank 3, facultative oxygen tank 4, and aerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com