PVC plastic absorbing film and method for transferring the same to plate surface

A transfer printing film and plate technology, which is applied in the printing of special varieties of printed matter, the process for producing decorative surface effects, and the transfer of ink from original manuscripts, etc. It can solve the problems of short service life, PVC decorative film falling off, furniture or plate Lose the beauty and other problems, to achieve the effect of improving the service life, good environmental protection, and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

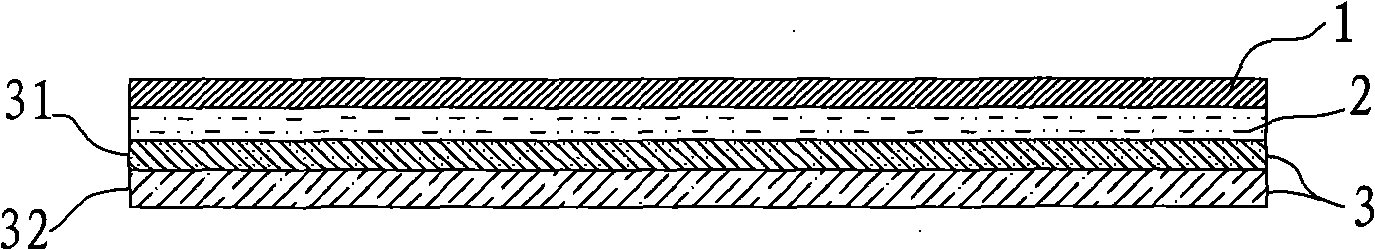

[0017] refer to figure 1 , a PVC blister transfer film, comprising a PVC film layer 1, the bottom surface of the PVC film layer 1 is provided with a release layer 2, and a textured ink layer 3 is printed on the bottom surface of the release layer 2, except for the wood grain pattern The ink layer can be prepared into layers with various textures and patterns according to actual conditions.

[0018] In the present invention, the ink layer 3 is composed of an ink texture layer 31 and an ink base color layer 32 .

[0019] In the present invention, the PVC film layer 1 has a thickness of 50-100 μm, and the ink layer 3 has a thickness of 3-7 μm.

[0020] A method for blister transfer of PVC plastic-absorbing transfer film to the surface of a plate, the process steps are as follows:

[0021] (1) First, spray 1-2μm thick glue on the surface of medium and high density wood boards or artificial stone boards, usually the glue is a common oily glue;

[0022] (2) Put the plate and PVC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com