Simulation synchronously impressing patterns and facing artificial board production process

A production method and technology of wood-based panels, which are applied to the imitation of natural patterns, the technology for producing decorative surface effects, the joining of wooden veneers, etc., which can solve the distortion of three-dimensional simulation patterns, difficult process control, and high production costs. problem, achieve good simulation effect, avoid incompatibility, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

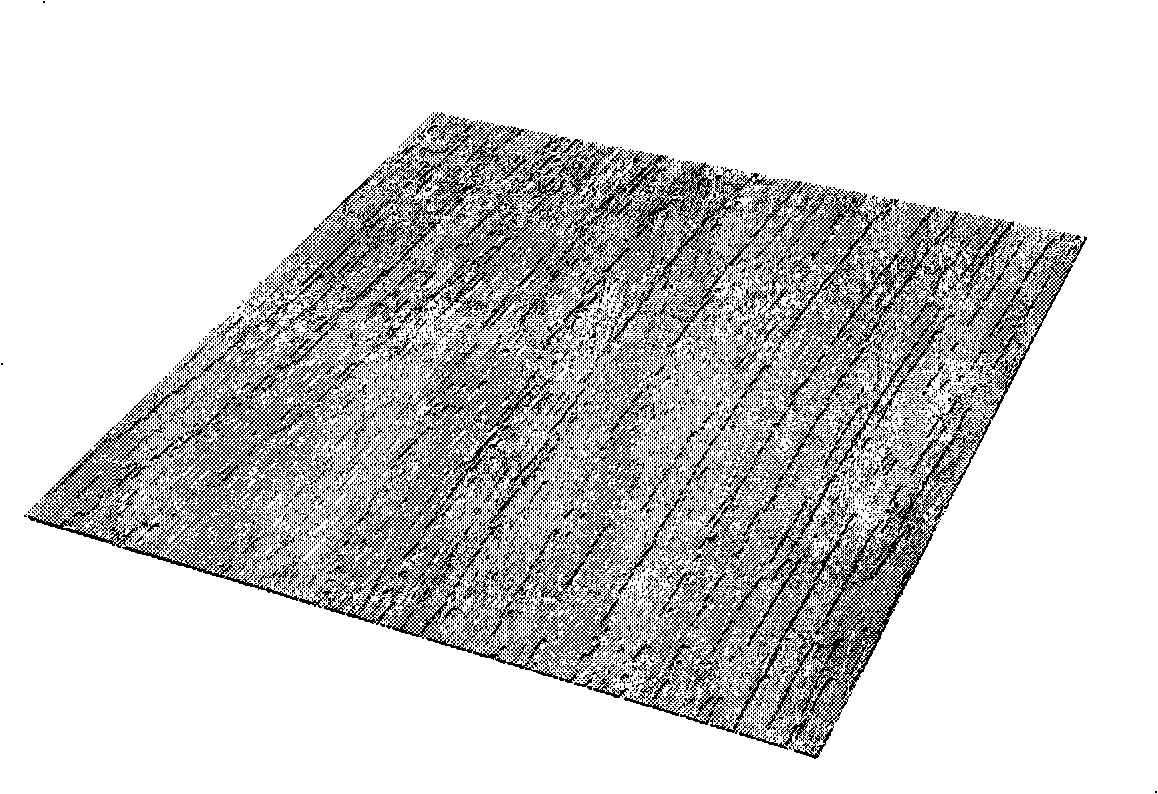

[0049] A production method of simulated synchronous printed decorative wood-based panels. The wood-based panels can be: laminate flooring, wall panels, ceilings, furniture panels and other decorative panels, which consist of the following steps:

[0050] The first step is to photograph the real object to obtain the physical pattern, and use computer image processing technology to decompose the pattern into two corresponding parts: the background color pattern and the template expressing the concave-convex texture effect. Commercial Photoshop 7.0 software can be used, and the physical pattern can be The solid wood grain can also be other patterns with three-dimensional effects, such as natural marble patterns, and even the pattern can be a three-dimensional pattern designed by the designer according to the actual object. After the patterns are separated, the background color pattern is usually repaired to eliminate spots , Especially to add a background color pattern to the blank p...

Embodiment 2

[0057] A method for producing artificial boards with simulated synchronous printing, taking laminate flooring as an example, consists of the following steps:

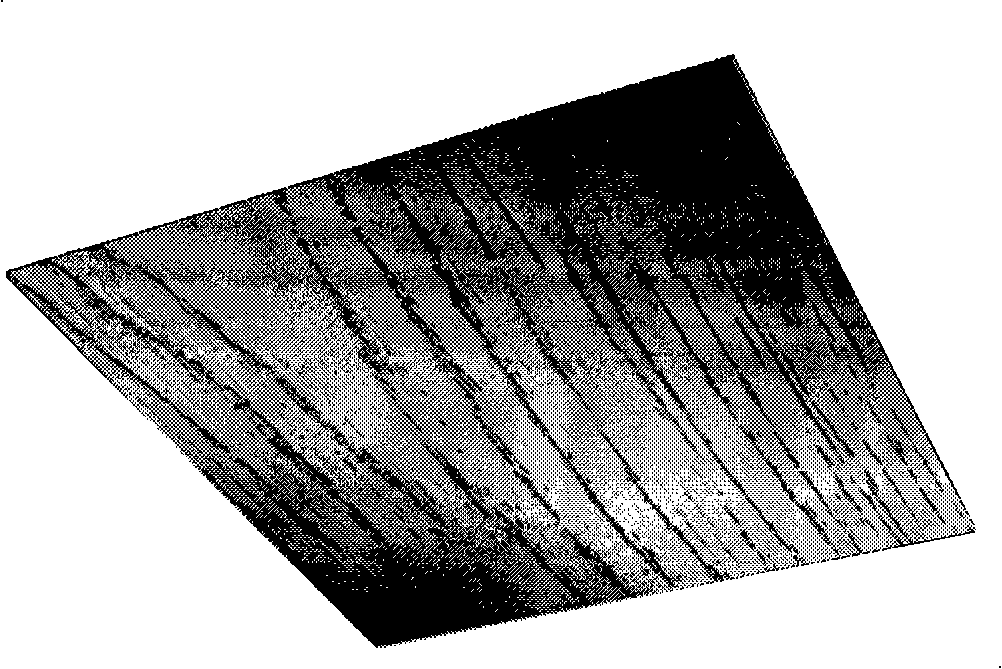

[0058] The first step is to take a solid wood image, and use computer image processing technology to decompose the pattern into two corresponding parts: the background pattern 1 and the template 2 expressing the concave-convex texture effect. Commercial photoshop7.0 software can be used to reflect the concave-convex effect. When the pattern is selected, first remove the surrounding background color as a relief layer; then remove the pattern that reflects the bump effect and leave the background color as the background color layer; make a relief (convex-concave) effect on the relief layer, And on the background color layer corresponding to the uneven texture-the blank part, fill in the wood grain background color, take the solid wood pattern as an example, shoot the actual pattern to obtain the pattern, in the solid wood pat...

Embodiment 3

[0066] The other steps are the same as in Example 2, wherein the hot pressing conditions are combined as follows:

[0067] Serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com