Fewer stands longitudinal hot rolling minor diameter thin wall seamless steel tube rolling technique and equipment thereof

A seamless steel pipe and small-diameter technology, applied in metal processing equipment, other manufacturing equipment/tools, metal rolling, etc., can solve the problems of difficult processing, high energy consumption, and environmental protection pressure, and achieve fast speed and high efficiency , the effect of uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

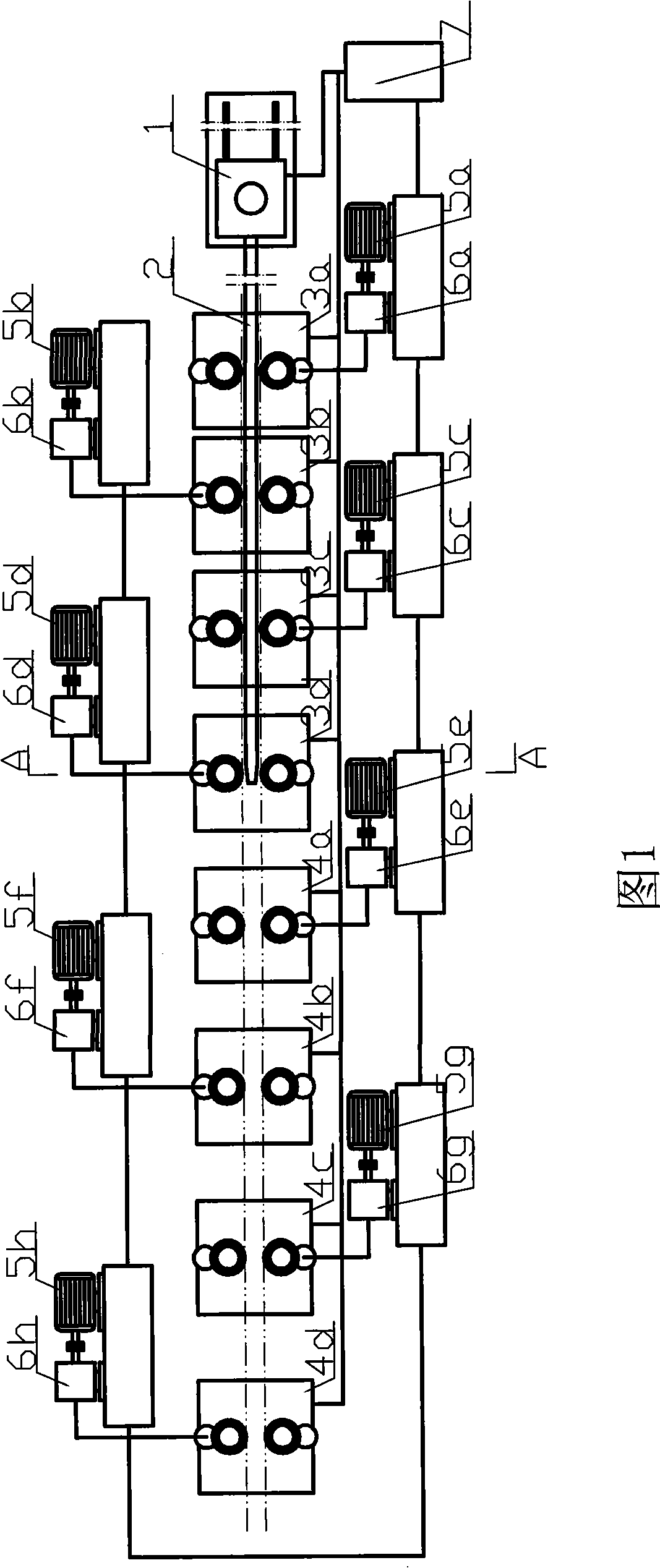

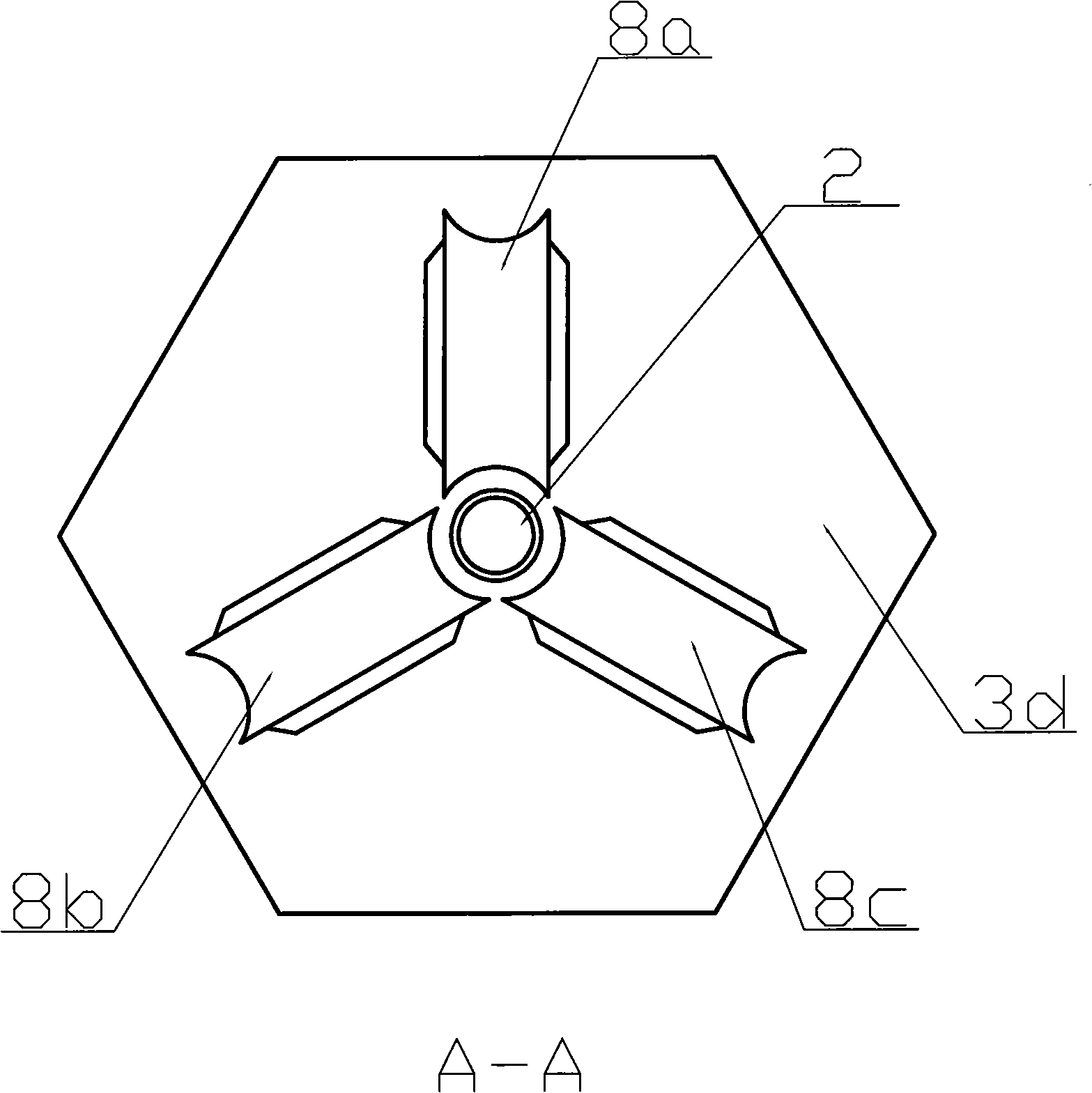

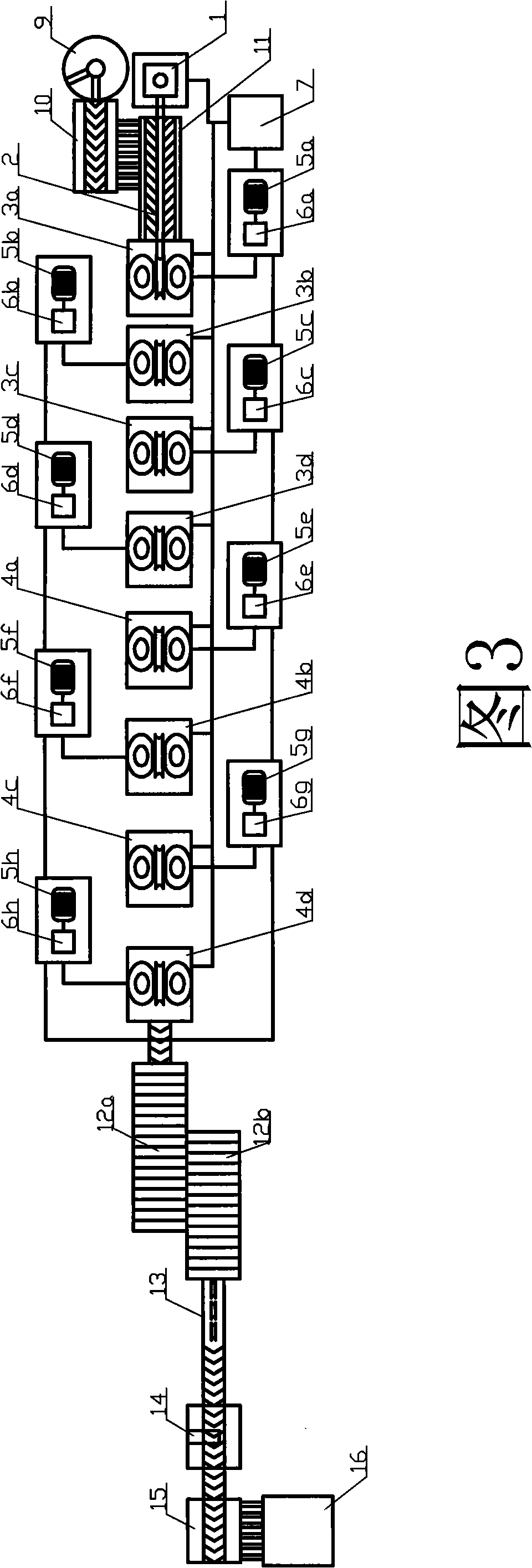

[0014] The present invention is further described in conjunction with accompanying drawings.

[0015] The rolling process implemented in the present invention is as follows: use a heating furnace to heat the blank tube to 950--1150°C, use a manipulator to send the heated blank tube to the feeding roller table, and the mandrel trolley penetrates the mandrel into the heated blank tube to push Go forward and push the blank tube into the wall-reducing rolling unit composed of multiple wall-reducing rolling machines to carry out longitudinal wall-reducing rolling on the blank tube, and the mandrel trolley sends the end of the mandrel along with the blank tube to the wall-reducing rolling The unit stops after the last stand, and the mandrel trolley pulls the mandrel away from the rolled steel pipe and the rolling mill, retreats to the starting position, and begins to roll another waste pipe, so the rolling cycle is repeated. Continue to push the blank tube that has been separated fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com