Welding technique for rolled steel

A welding process and welding speed technology, applied in the field of steel welding, can solve the problems of serious heat-affected zone embrittlement, reducing austenite stability, increasing austenite overheating, etc., reducing infrastructure investment and reducing steel consumption. , the effect of increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

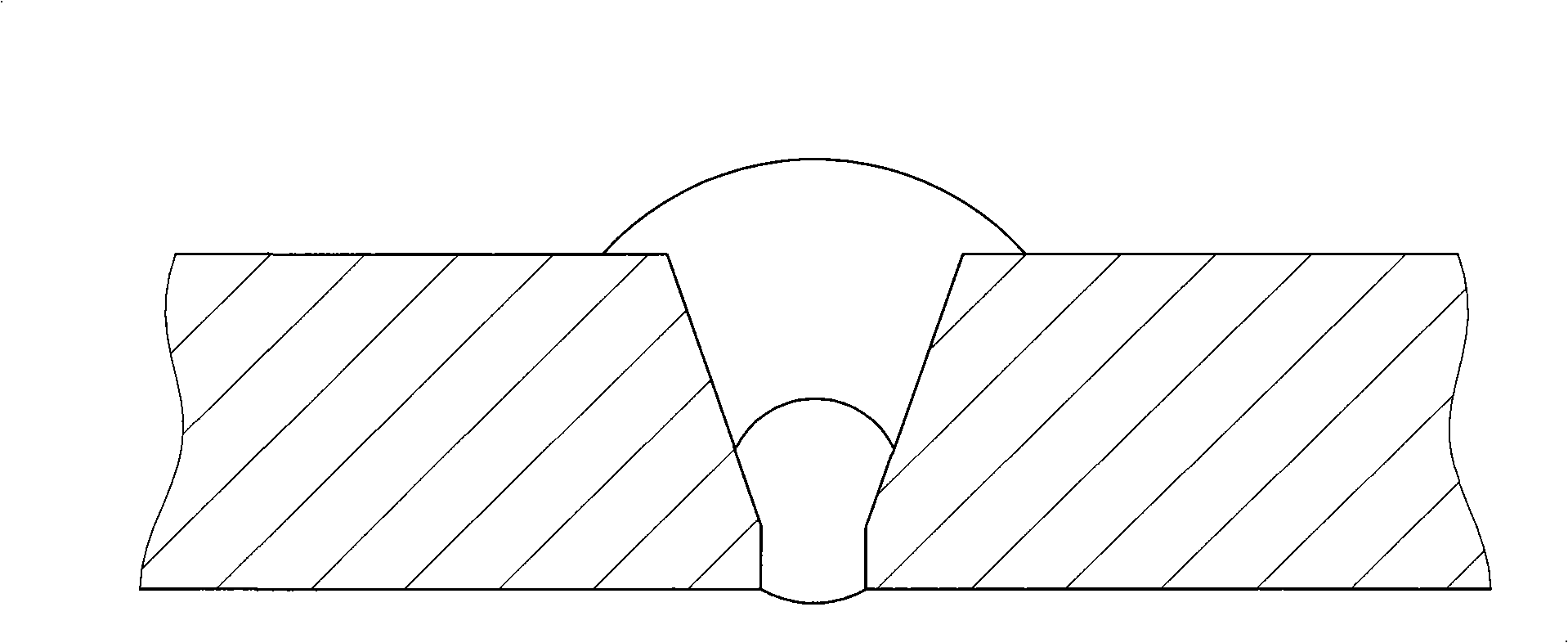

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] refer to figure 1 , a welding process for ASTM A572 GR.65 steel, in an operating environment above 5°C, using argon and carbon dioxide mixed gas shielded welding for bottom welding, using argon / carbon dioxide mixed gas shielded welding for filling and cover welding , follow these steps:

[0037] The present invention carries out rigorous and detailed design on the process, and provides a normative process operation code for the welding of ASTM A572 GR.65 steel.

[0038] (1). Determination of welding process parameters

[0039] The heat-affected zone of ASMT A572 GR.65 steel is prone to produce low-plasticity hardened structure, and the hardening tendency increases with the increase of material thickness, which is prone to cold cracks. The use of larger welding heat energy can reduce the hardening tendency, but due to the large hardening tendency of this steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com