Method for operating an internal combustion engine and device for implementing the method

A technology of internal combustion engine and equipment, applied in the field of equipment implementing the method, to achieve high precision, avoid reagent leakage, and avoid low dose effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

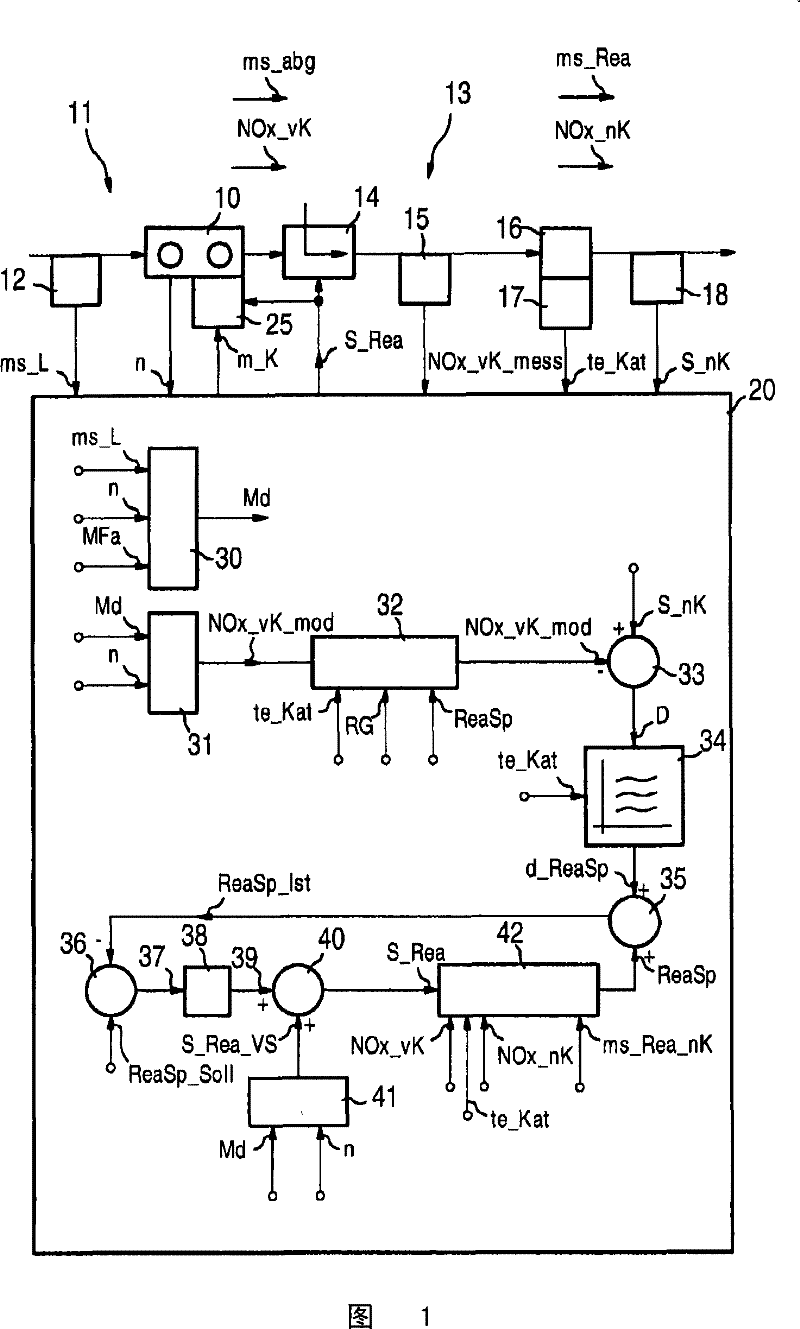

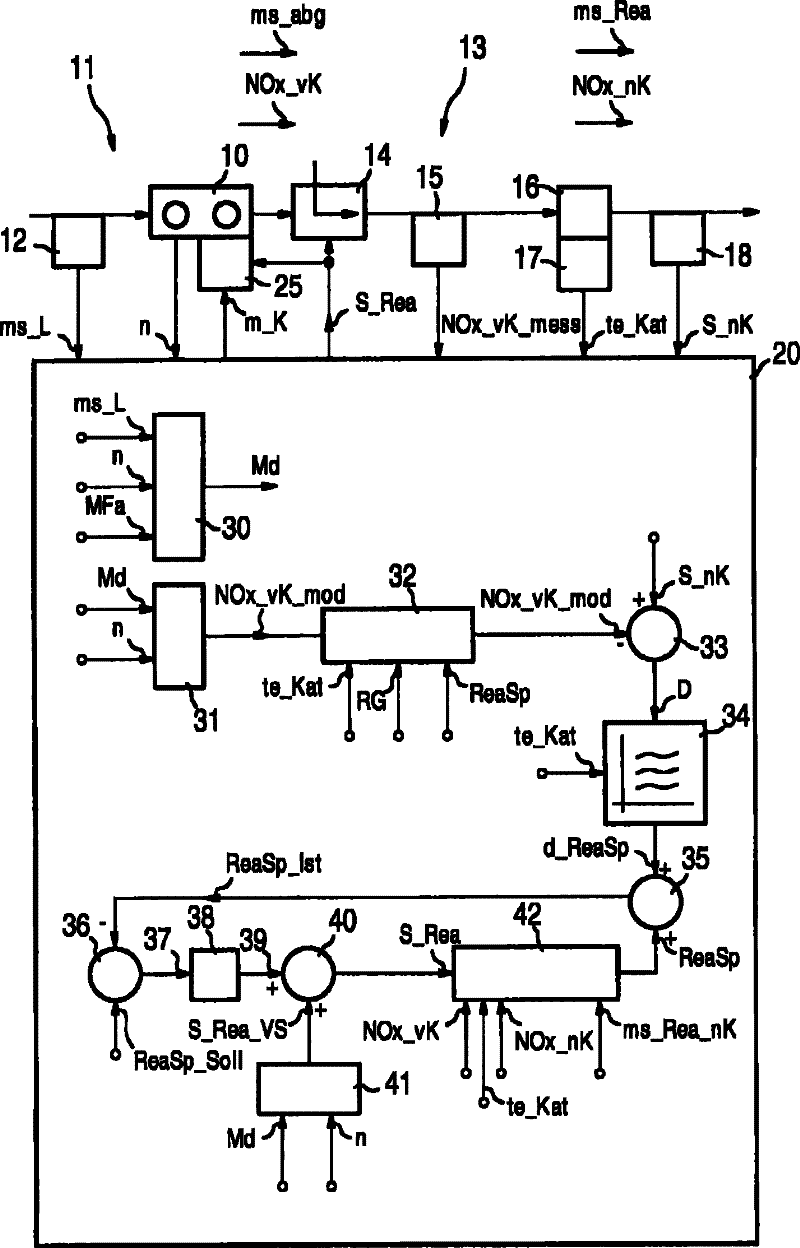

[0023] The figure shows an internal combustion engine 10 . An air detection device 12 is arranged in the intake region 11 of the internal combustion engine 10 and a reagent metering device 14 , a first NOx sensor 15 , an SCR catalytic converter 16 , an associated SCR catalytic converter 16 are arranged in the exhaust gas region 13 of the internal combustion engine 10 . A temperature sensor 17 and a second NOx sensor 18 .

[0024] Downstream of internal combustion engine 10 , exhaust gas flow ms_abg and NOx untreated concentration (NOx-Rohkonzentration) NOx_vK occur. The NOx concentration NOx_nK and the reagent leakage ms_Rea_nK occur downstream of the SCR catalytic converter 16 .

[0025] The air detection device 12 provides the air signal ms_L to the controller 20, the internal combustion engine 10 provides the rotation signal n, the first NOx sensor 15 provides the first NOx signal NOx_vK_mess, the temperature sensor 17 provides data indicating the temperature te_Kat of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com