Projector

A technology for projectors and wind guides, which is applied in the field of projectors, and can solve the problems of increased airflow resistance, increased power, inability to effectively control the temperature of the light guide tube 20 and the color wheel motor 32, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

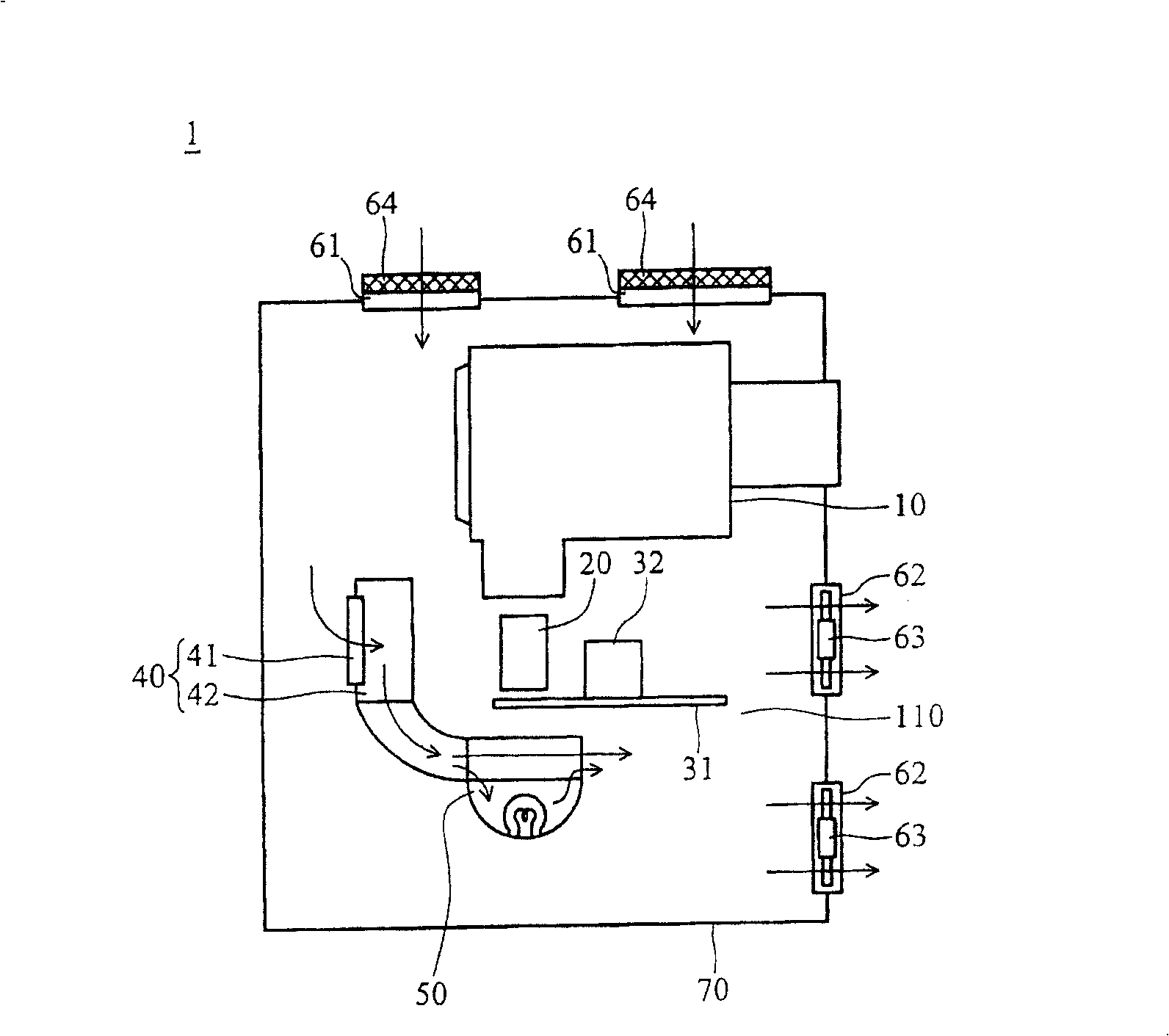

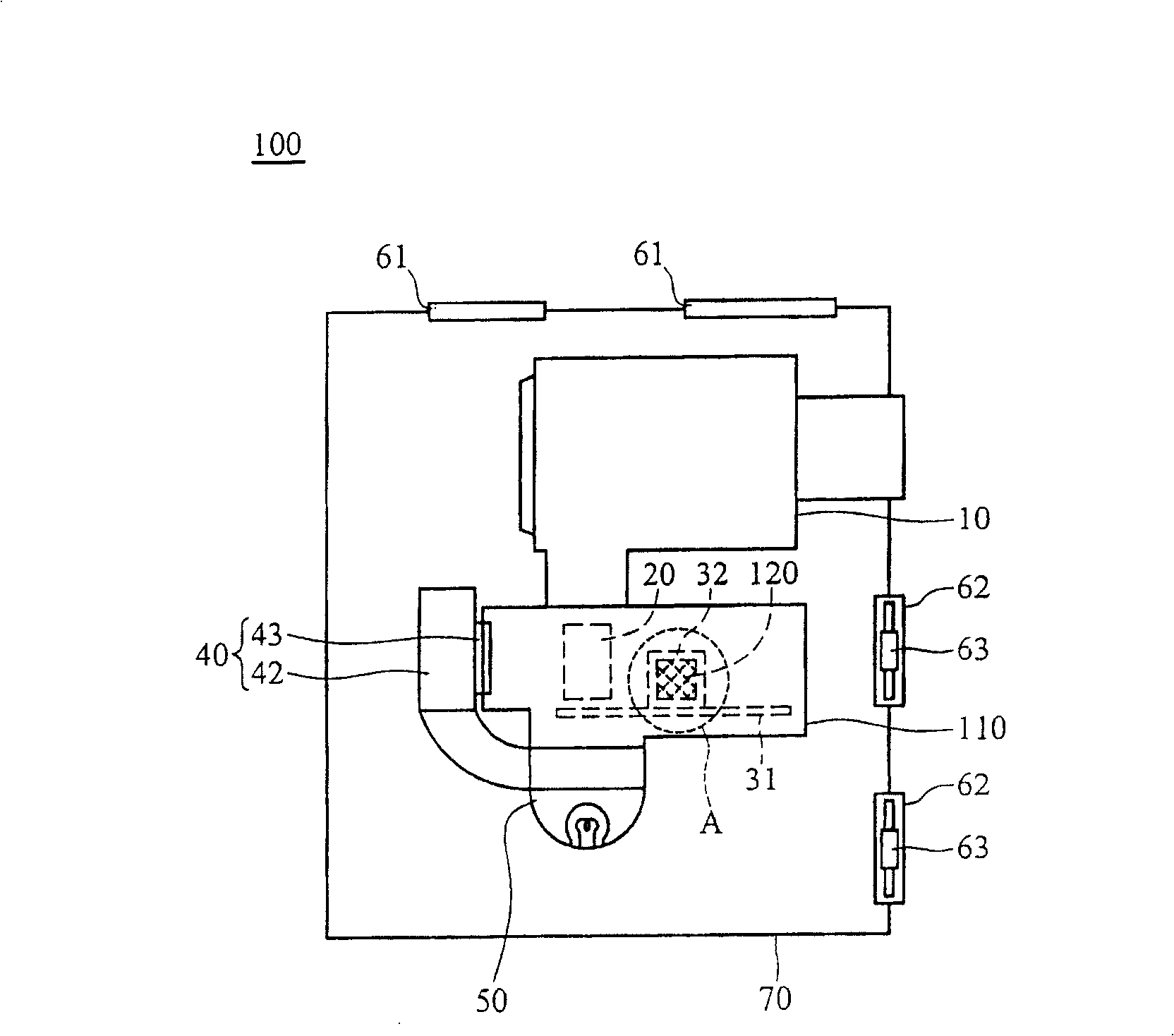

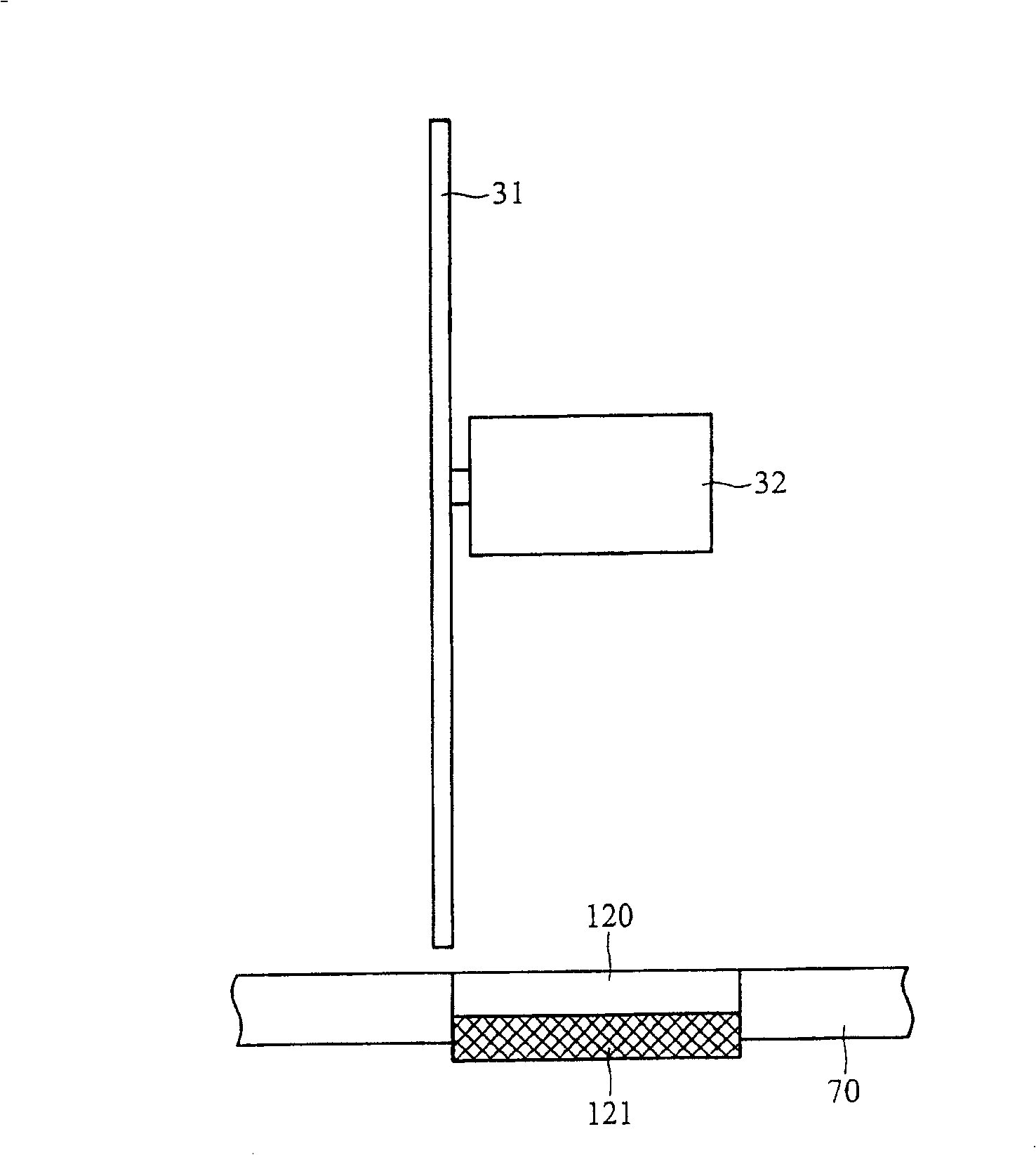

[0038] refer to Figure 2a , which shows the projector 100 according to the first embodiment of the present invention, including a lens module 10, a light guide pipe 20, a color wheel 31, a color wheel motor 32, a fan module 40, a light source module 50, and a system air inlet 61 , the system air outlet 62 , a casing 70 , a wind guide cover 110 and a first air inlet 120 . The lens module 10 , the light pipe 20 , the color wheel 31 , the color wheel motor 32 , the fan module 40 , the light source module 50 and the air guide cover 110 are disposed in the casing 70 . The system air inlet 61 , the system air outlet 62 and the first air inlet 120 are opened on the housing 70 . The first air inlet 120 is located below the color wheel motor 32, and corresponds to the color wheel motor 32. Figure 2b , which shows Figure 2a In the side view of part A, the first air inlet 120 is provided with a filter screen 121 . A system fan 63 is disposed in the system air outlet 62 . The fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com