Yarn feeding device for fluid jet loom

A technology of fluid jetting and feeding device, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of detachment of covering parts, loss of bonding function, unimproved, etc., to improve thermal conductivity and heat dissipation effect. High, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

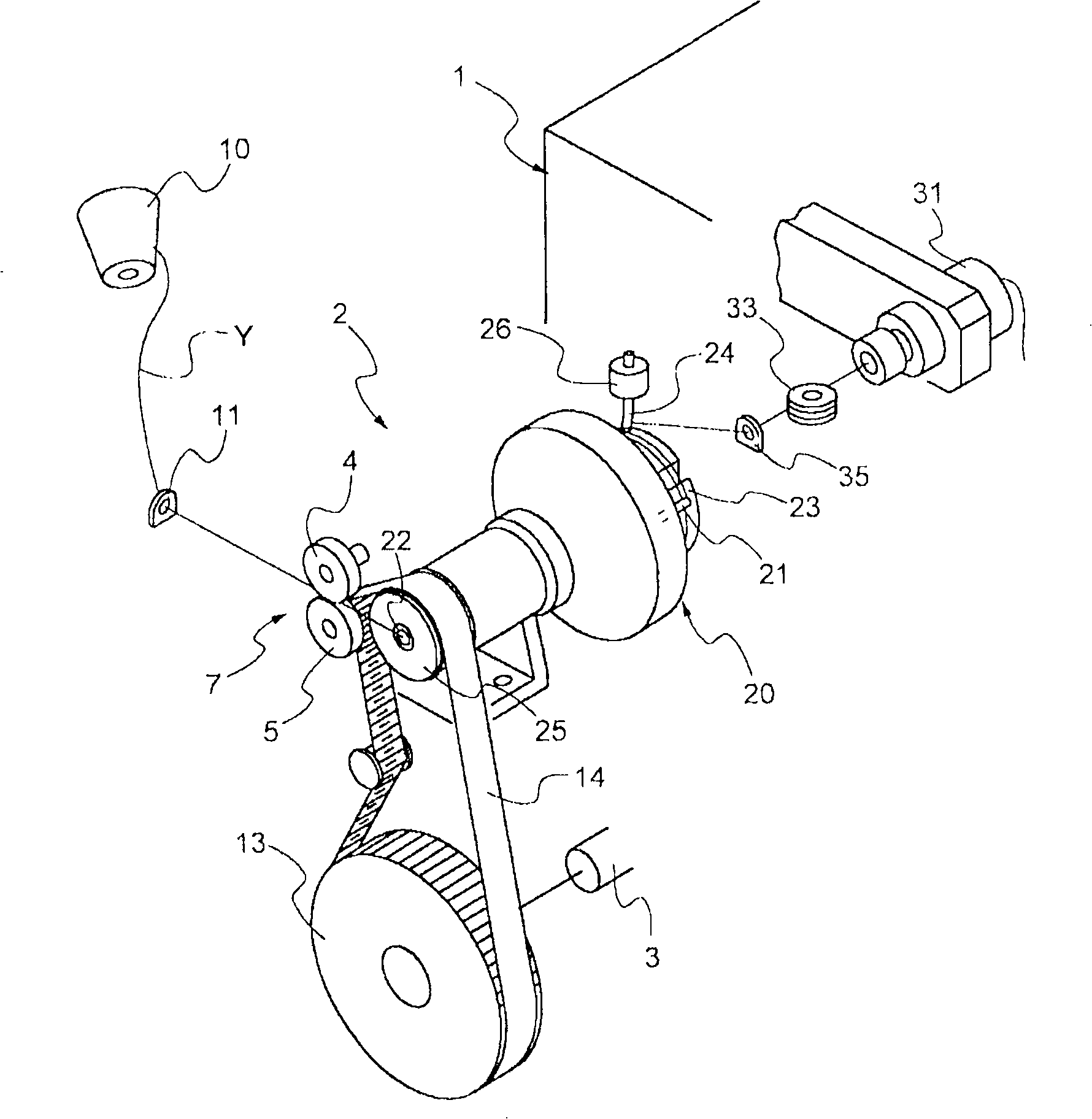

Embodiment 1

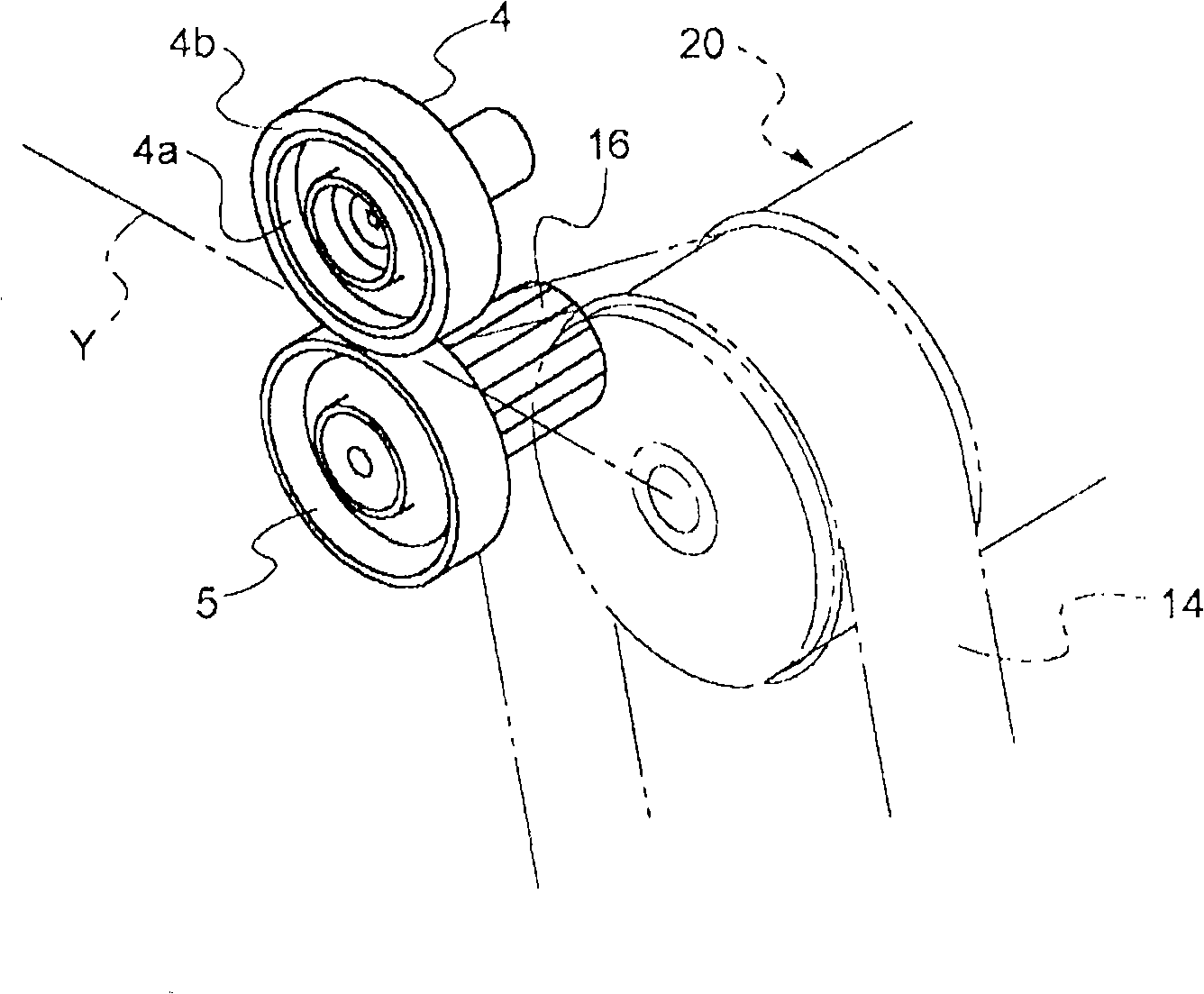

[0048] Here, iron-based materials ( ), aluminum materials ( ), copper-based materials ( ) to form a roller, and the case where the roller is used for the driven roller 4 of the length measuring section 7 in the above-mentioned weft yarn length measuring storage device 2 will be described based on the results of a durability test. In this test, as the driven roller 4, a roller having an outer peripheral diameter of 65 mm and a thickness of the covering member 4b made of polyurethane of 3.5 mm (outer peripheral diameter of the roller 4a: 58 mm) was used. Then, in a water-jet loom with a passing width of 170 cm, in order to shorten the test time, the number of revolutions of the loom was set to 2000 rpm (peripheral speed of the roller: 3400 m / min), which was much higher than the actual level, A test in which the loom was continuously operated for 240 hours was carried out.

[0049] As a result of this test, in the driven roller 4 in which the roller 4a was formed of an ...

Embodiment 2

[0056] In this example, not only the material is different for the roller 4a according to the first example, but also the width of the yarn nip surface 4b1 of the driven roller 4 is considered, and the durability of the case where the width is changed is determined. Explain differently. In addition, as an example of the driven roller 4, a roller having a roller 4a formed of an aluminum-based material is used as an example of the driven roller 4, and the durability of a plurality of rollers having different widths of the yarn nip surface 4b1 on the driven roller 4 is described. the results of the test.

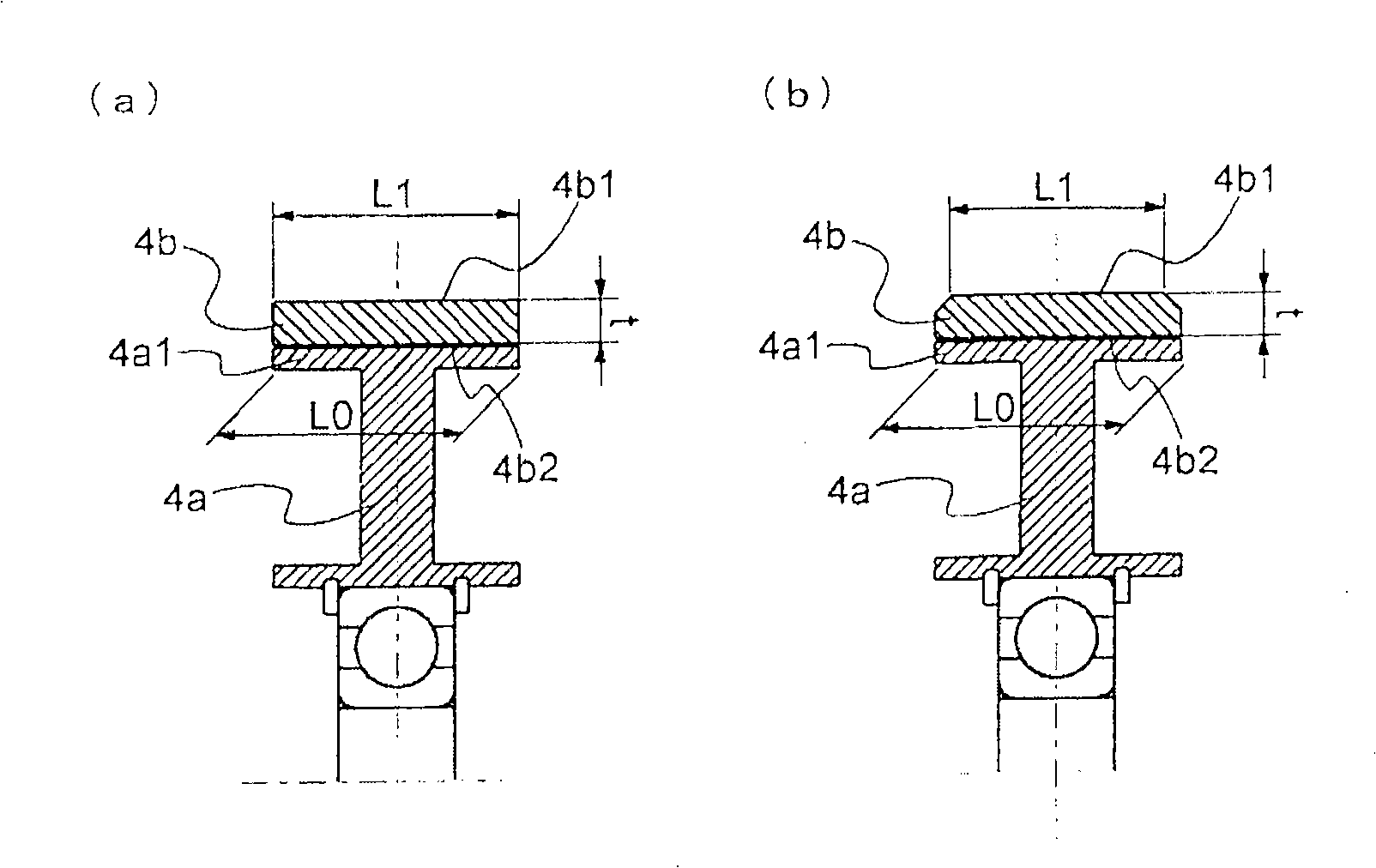

[0057] In the above test, more specifically, the driven roller 4 ( image 3 ) includes a roller 4a with a width L0 of the outer peripheral portion 4a1 of 16.5 mm, and a covering member 4b made of polyurethane rubber, which is formed as an end surface on the side of the roller 4a (=joint surface 4b2 with the roller 4a) The width is equal to the width L0 of the outer peripheral...

Embodiment 3

[0065] In this example, further focusing on the thickness of the covering member 4b on the driven roller 4, the difference in durability when the thickness is changed will be described. In addition, in the following description, the driven roller 4 in which the roller 4a is formed of an aluminum-based material is taken as an example, and the durable The results of the sex test.

[0066] In the above-mentioned test, more specifically, using a roller having a width of 15 mm in the yarn nip surface 4b1 of the driven roller 4 used in the above-mentioned Example 2, the thickness t( image 3 ) was formed to be 5 mm, 4.5 mm, 4 mm, and 3 mm (t = 3.5 mm in the driven rollers 4 of Examples 1 and 2), and the durability test was carried out. In addition, the outer peripheral diameter of each driven roller 4 was set to 65 mm as described in the first embodiment. Furthermore, the loom used for the test and its operating conditions were the same as those in Examples 1 and 2 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com