High-strength steel for water heater inner container and production method thereof

A water heater liner, high-strength technology, applied in the field of hot-rolled plate manufacturing, high-strength water heater liner steel, can solve the problems of poor pressure resistance, easy deformation of enamel, complicated welding process, etc., to achieve excellent pressure resistance, Less microalloying elements and good cold formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

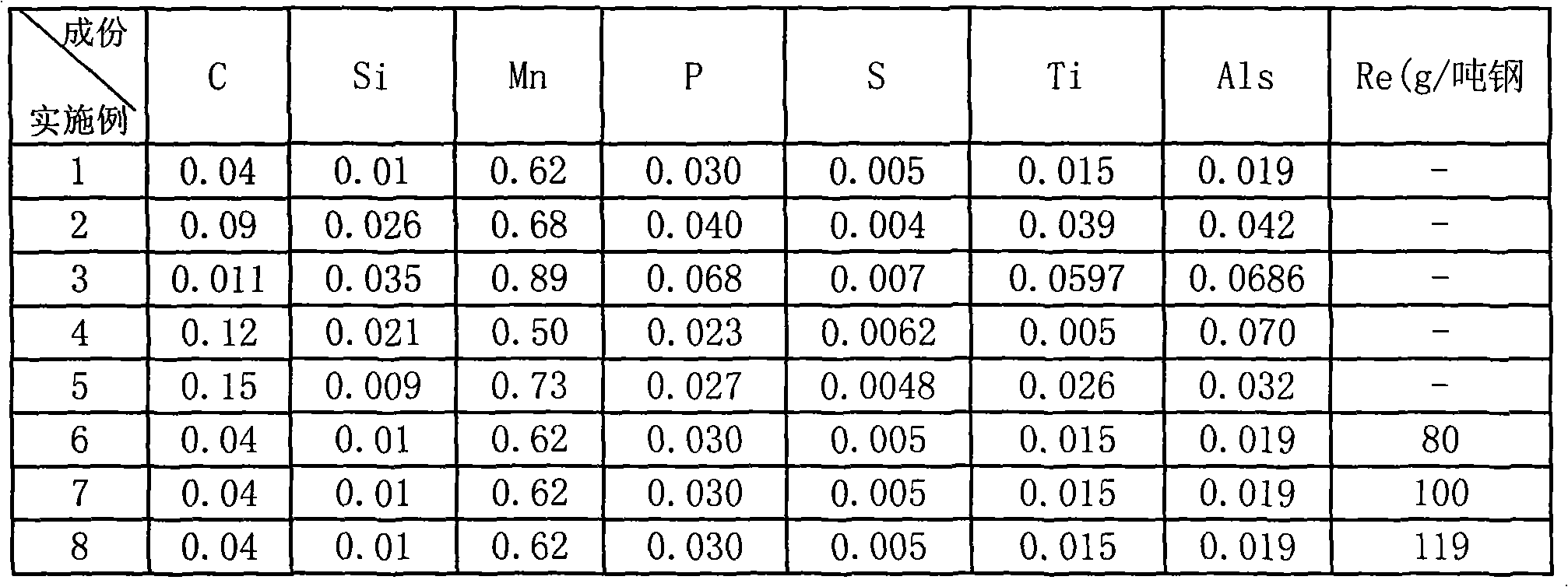

[0032] Below in conjunction with specific embodiment the present invention is described in further detail:

[0033] Table 1 lists the chemical composition of specific examples of the present invention.

[0034] The technological system of production embodiment:

[0035] 1) Desulfurization of molten iron and compound blowing of the top and bottom of the converter are carried out. During the compound blowing of the top and bottom of the converter, Al is added first, and then Ti is added. The yield of Ti is required to be greater than or equal to 90%;

[0036] 2) Perform argon blowing treatment for 3, 4, 5, 5.5, 6, 6, 7, 8 minutes:

[0037] 3) Perform full-protection casting into slabs, and control Si to not exceed 0.04%;

[0038] 4) Use controlled rolling and controlled cooling for hot rolling:

[0039] a, the slab is heated, and the heating temperature is shown in Table 2;

[0040] b. Carry out rough rolling, control the reduction rate of each pass at 28, 25, 27, 30, 31, 32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com