Non-aqueous solution homogeneous phase reduction preparation of nano metallic ruthenium

A nano-metal, non-aqueous solution technology, applied in the field of non-aqueous solution homogeneous reduction preparation of nano-metal ruthenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

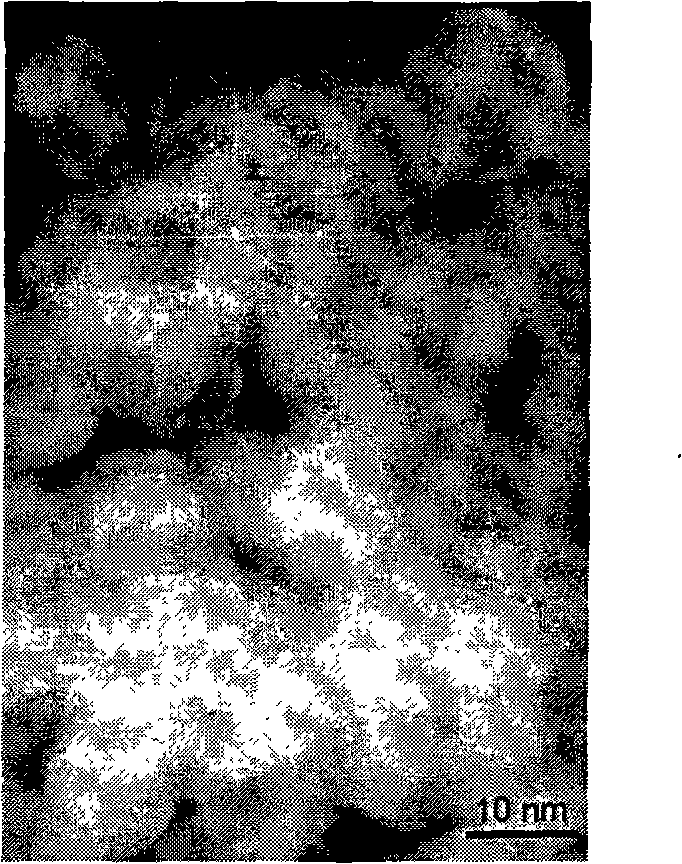

Image

Examples

preparation example Construction

[0017] Preparation steps of the present invention:

[0018] (1) According to the concentration range, the basic coordination compound used to absorb ruthenium ions is dissolved in an inert solvent to become carrier solution I, and the neutral coordination compound or neutral coordination compound used to absorb monovalent copper ions The compound is mainly dissolved in an inert solvent into a coordination compound in which an acidic coordination compound is added to become a carrier solution II;

[0019] (2) dissolving the compound containing ruthenium ions in carrier solution I to prepare reaction solution I, and preparing a source solution containing ruthenium ions, dissolving monovalent copper ions in carrier solution II to prepare reaction solution II;

[0020] (1) The reaction solution I obtained in the step (2) is mixed with the step reaction solution II to generate a reaction, the volume ratio of the two reaction solutions is 4:1~1:4, stirring and mixing, and observing ...

Embodiment 1

[0024] First, trioctylamine is dissolved in kerosene, and it is prepared into 1 liter of carrier solution, and the volume concentration of the coordination compound is 20%; Ruthenium nitrate is dissolved in it, and it is prepared into a saturated reaction solution containing ruthenium ions; then copper nitrite is dissolved in In the kerosene containing tributyl phosphate 20% and two (2-ethylhexyl) phosphoric acid 10%, be mixed with the reaction solution 0.3 liters of saturated monovalent copper ion; Contain ruthenium reaction solution and contain monovalent copper ion The reaction solution was mixed with a volume ratio of 3:1, and stirred electrically for 120 minutes. After the reaction was completed, after standing for 6 hours, it can be seen that the solution gradually changed from brown to dark green, and turned grayish black due to the generation of precipitates; The solution of the compound is filtered through filter paper, washed with acetone, and dried to obtain nano-met...

Embodiment 2

[0026] First, trilaurylamine is dissolved in paraffin oil to prepare 1 liter of carrier solution, and the volume concentration of the coordination compound is 15%; ruthenium nitrate is dissolved in it to prepare a saturated reaction solution containing ruthenium ions; then copper nitrite is dissolved In paraffin oil containing 10% of di(2-ethylhexyl) phosphate (2-ethylhexyl) ester and 20% of n-butyl dibutyl phosphate, prepare a saturated reaction solution containing monovalent copper ions 0.2 liter; the ruthenium-containing reaction solution and the reaction solution containing monovalent copper ions were mixed with a volume ratio of 2:1, stirred electrically for 60 minutes, and the reaction was completed. After standing for 8 hours, it can be seen that it gradually changed from brown to dark green, and then It turns gray and black due to the generation of precipitates; filter the solution containing the generated precipitates through filter paper, wash with acetone, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com