Display quality testing apparatus and testing method

A detection device and display quality technology, which is applied in the direction of optical testing flaws/defects, optics, instruments, etc., can solve the problems of large human errors, high cost of halogen lamps, wrong judgments, etc., and achieve the effect of avoiding errors and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above content of the present invention more comprehensible, a preferred embodiment will be described in detail below together with the accompanying drawings.

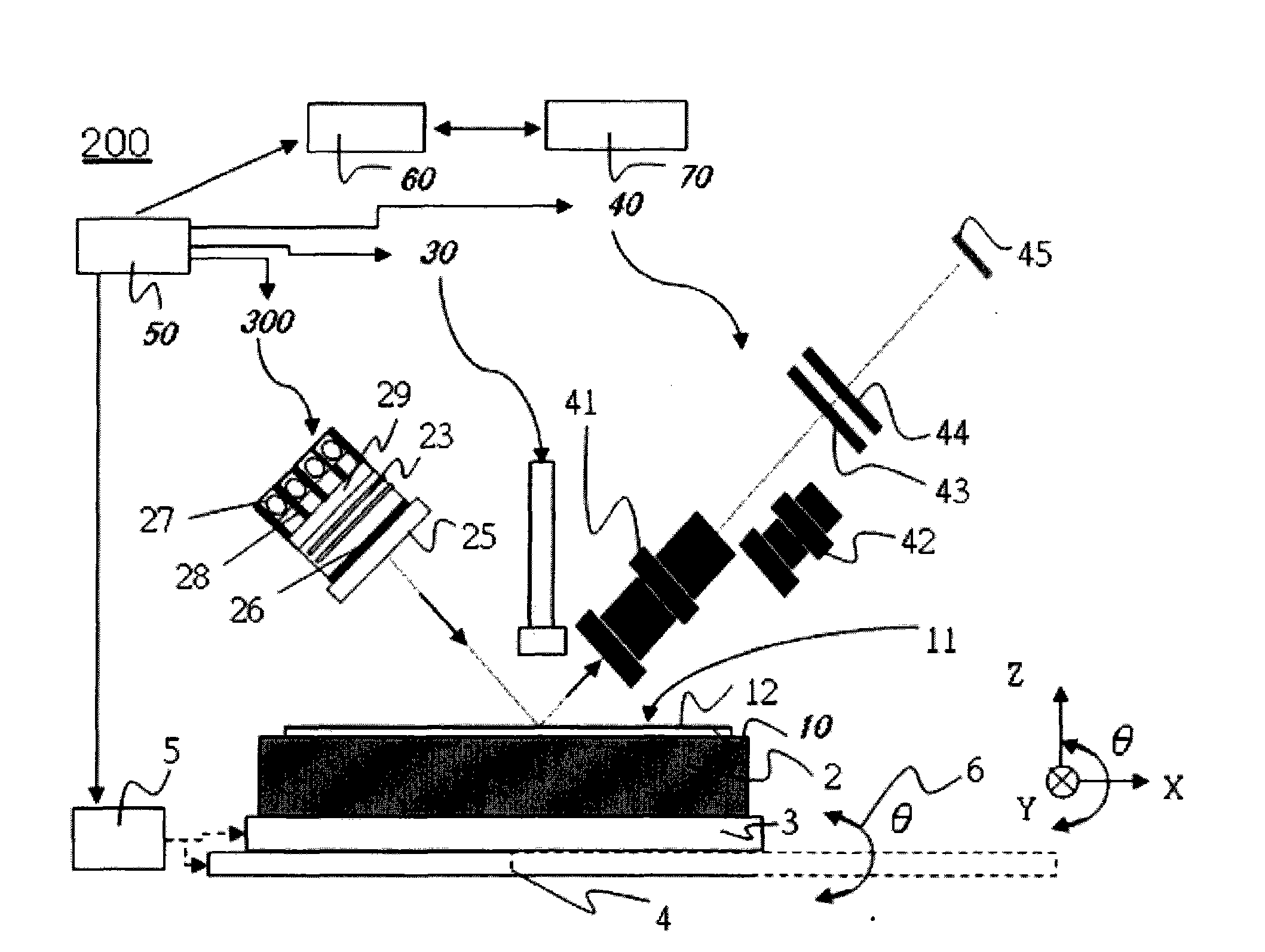

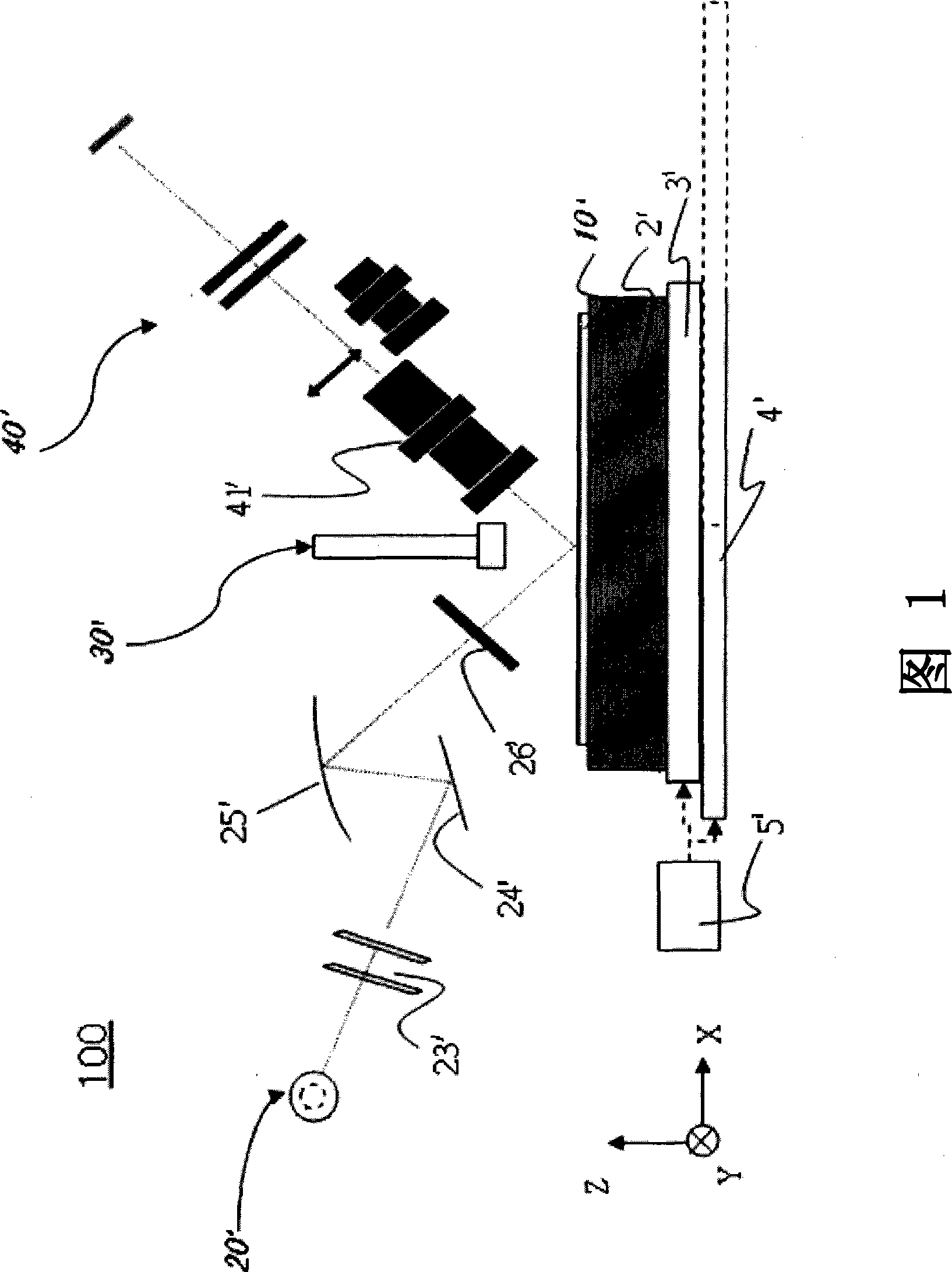

[0026] figure 2 middle,

[0027] 2 platforms

[0028] 3Y direction travel axis

[0029] 4X direction travel axis

[0030] 5X, Y, θ direction control motor

[0031] 6θ axis rotation direction

[0032] 10 substrates to be tested

[0033] 12 film surface

[0034] 23 Density Correction Filters

[0035] 25. Lens lens module

[0036] 26. Polarizer

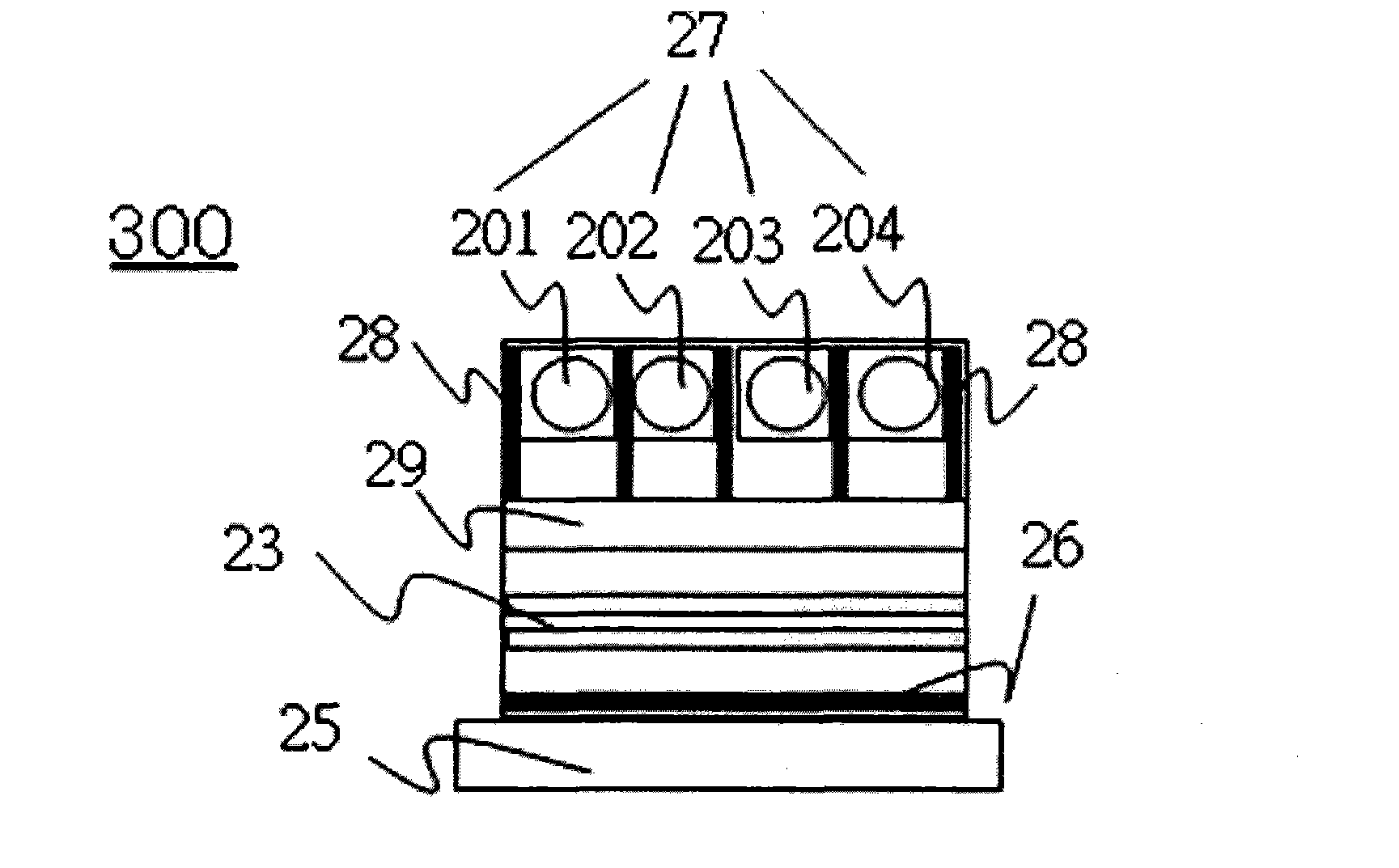

[0037] 27 point light sources

[0038] 28. Point light source visor

[0039] 29 light mixing board

[0040] 30 microscopic device

[0041] 40 imaging unit

[0042] 41 lens lens

[0043] 42 lens lens

[0044] 43 Phase modulation compensator (Compensator)

[0045] 44 Analyzer (Analyer)

[0046] 45 sensors

[0047] 50 control device

[0048] 60 detection device

[0049] 70 data storage device

[0050] 200 display quality inspection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com