Method and device for on-line monitoring high temperature superconducting cable conductor temperature

A cable conductor, high-temperature superconducting technology, applied in measurement devices, electrical devices, thermometers, etc., can solve the problems of signal distortion, difficult temperature monitoring, receiving stable and real signals at the receiving end, and achieve protection, safety, and use. Long life and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

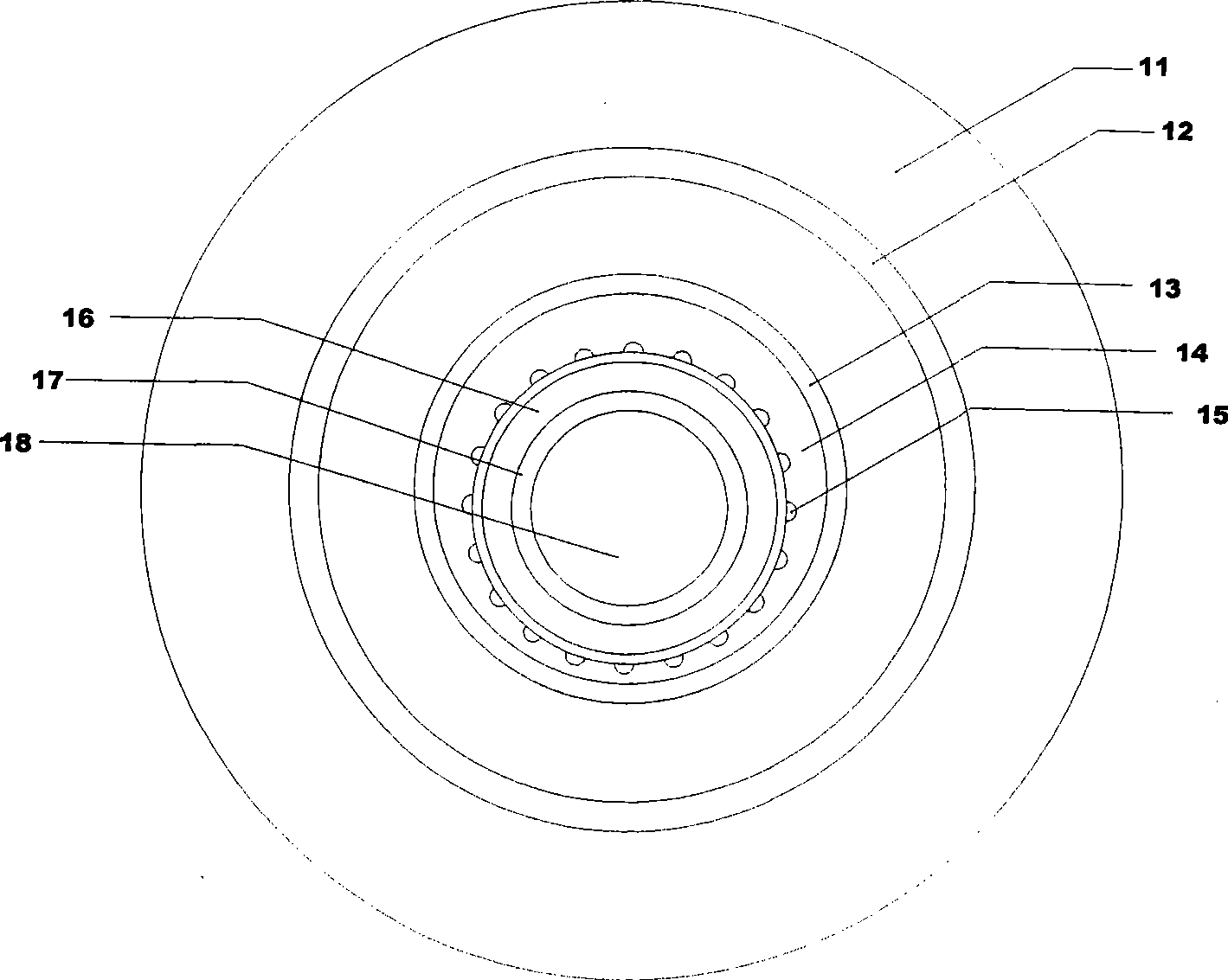

[0039] figure 1 is a cross-sectional view of a high temperature superconducting cable. The high temperature superconducting cable is composed of cable core, liquid nitrogen channels 14, 18, cryogenic containers 12, 13, electrical insulation 11 and other parts. The cable core of the high temperature superconducting cable is composed of a cable skeleton 17 , a cable conductor 16 and a slideway line 15 . The cable skeleton 17 adopts flexible stainless steel bellows, and the two ends are respectively welded with terminal copper joints, which facilitates the welding of the high-temperature superconducting strip of the conductor layer and the connection of the terminal current leads. The cable conductor layer 16 of the cable is made of a certain number of Bi-2223 / Ag tapes wound on the skeleton, and the conductor layers have low-temperature electrical insulation. The cable core is housed in a cryogenic container 13 that maintains the temperature of liquid nitrogen, and the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com