Coal mine down-hole foam dedusting system

A dust removal system and foam technology, applied in dust prevention, mining equipment, mixing methods, etc., can solve the problems that are not conducive to the film formation of foaming liquid, cannot realize continuous work, and poor foaming effect, etc., and achieve wide practicability, Small size, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

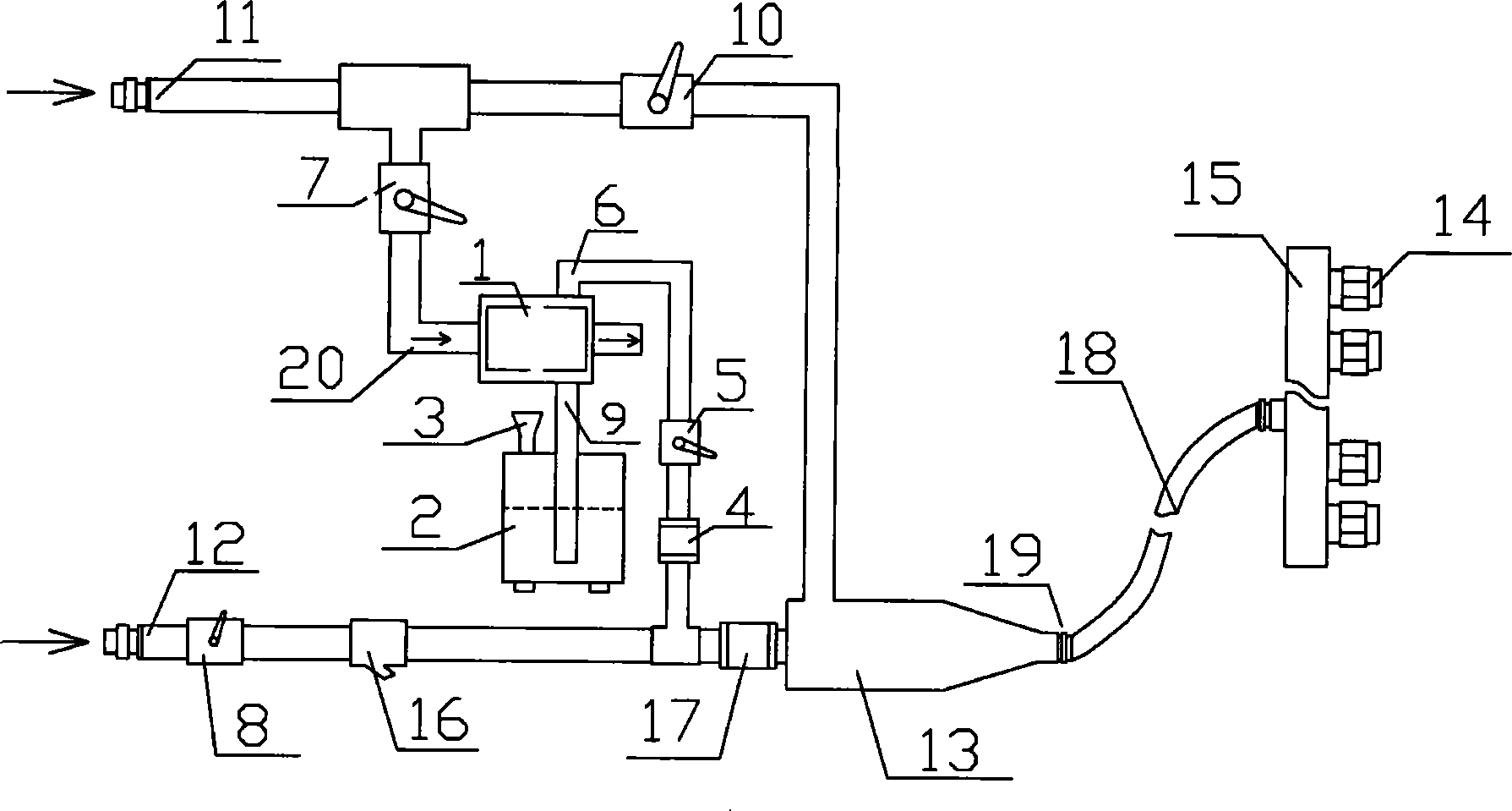

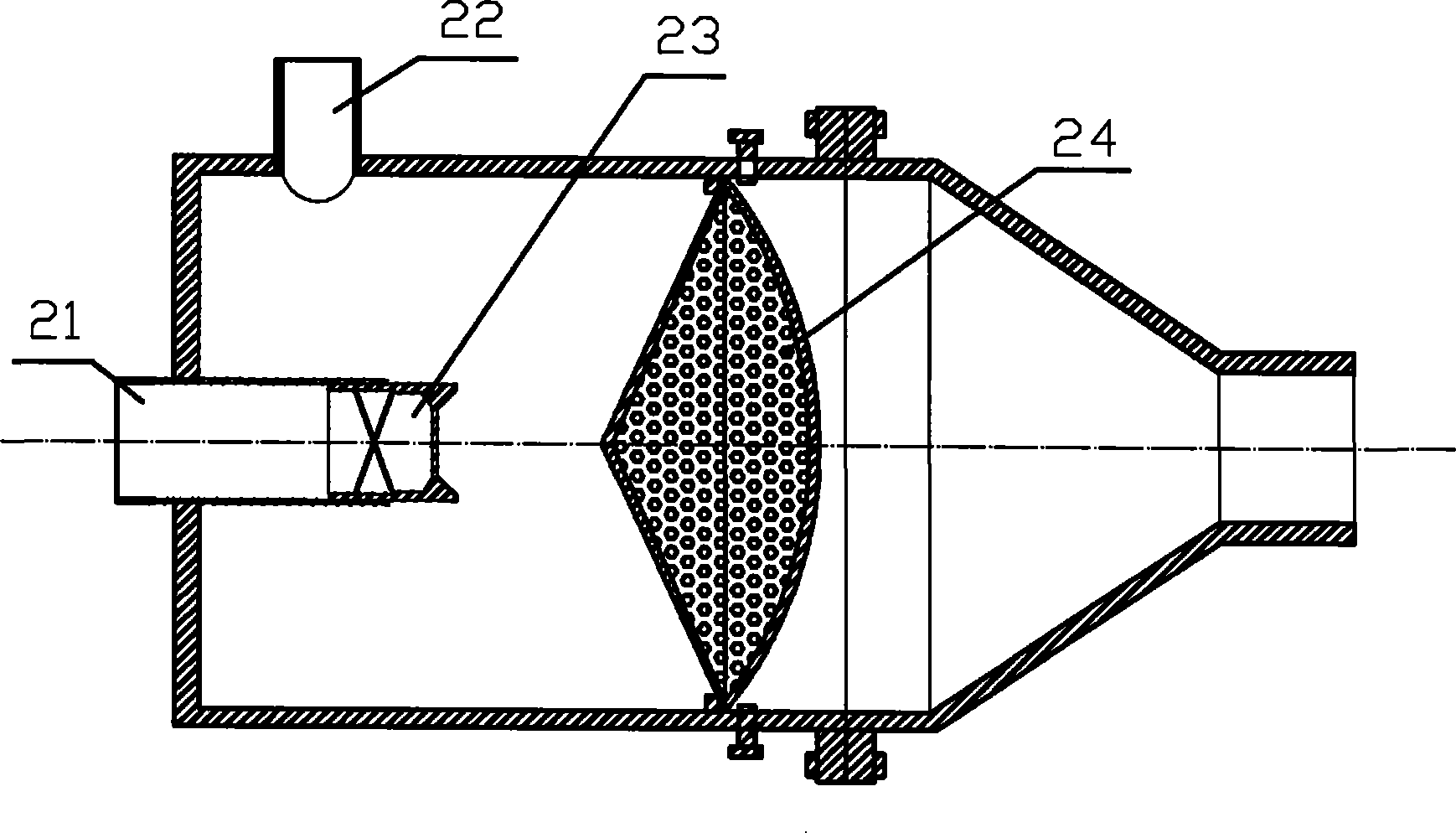

[0011] figure 1 As shown, it is mainly composed of a quantitative addition pump 1 with a small flow rate, a foaming agent liquid storage tank 2, a compressed air pipeline 11, a water inlet pipeline 12, a foamer 13, a foam nozzle 14 and other components. Wherein the foamer 13 is respectively connected with the compressed air pipe 11 and the water inlet pipe 12 through pipelines, and the pipeline connected with the compressed air pipe 11 is provided with a regulating valve 10, and the nozzle connected with the water inlet pipe 12 is successively provided with a regulating valve 8, Filter 16 and check valve 17; The quantitative addition pump 1 is connected between the compressed air pipe 11 and the water inlet pipe 12 connected with the foamer 13 respectively, and the intake pipe 20 of the quantitative addition pump 1 passes through the pipeline and the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com