Preparation of dialdehyde carboxymethyl cellulose and method for testing aldehyde group content

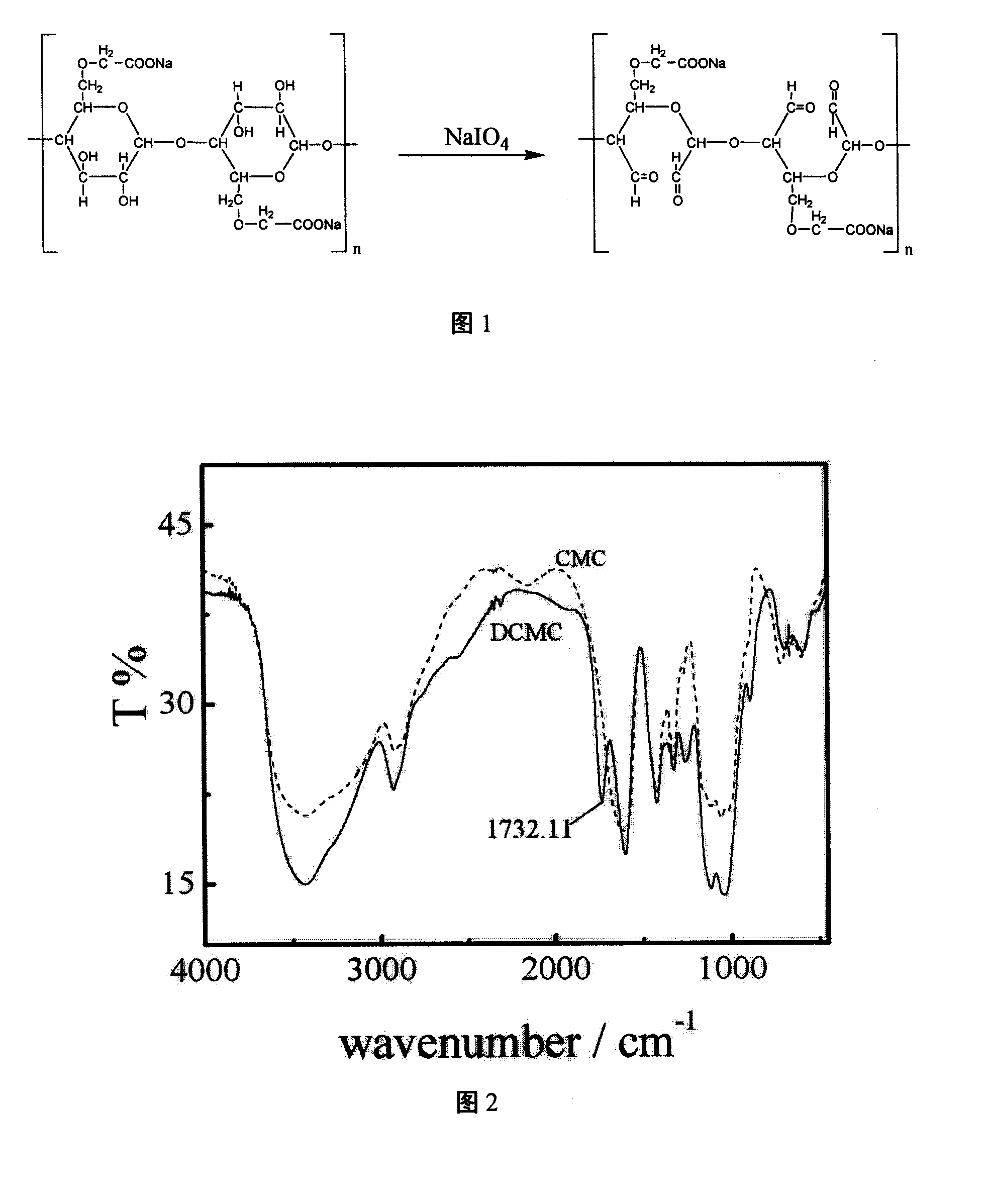

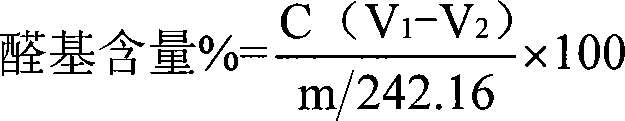

A technology of sodium carboxymethyl cellulose and dialdehyde carboxymethyl cellulose is applied in the field of preparation of dialdehyde carboxymethyl cellulose and the detection of aldehyde group content, so as to improve the utilization rate, avoid side reactions and improve the reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

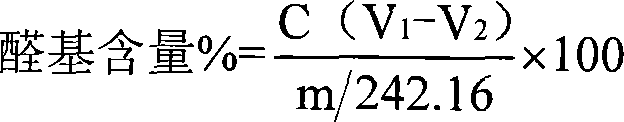

Embodiment 1

[0037] Weigh 100 parts of sodium carboxymethylcellulose and dissolve it with 20 times the volume of distilled water, then weigh 100 parts of sodium periodate and dissolve it with 10 times the volume of distilled water. Under the condition of about 35°C, sodium carboxymethylcellulose solution and sodium periodate solution are simultaneously added to the reactor equipped with stirring device and temperature testing device, and the pH of the reaction system is adjusted to 2.0 with sulfuric acid. After reacting for about 4hrs, pour the reaction liquid into the solution storage, add 5 times the volume of acetone for precipitation, filter and separate after sufficient precipitation, wash the precipitate alternately with distilled water and acetone until no iodate is detected in the washing liquid, and then dry , Crush to obtain dialdehyde carboxymethyl cellulose. The aldehyde group content of the dialdehyde carboxymethyl cellulose is determined by the hydroxylamine hydrochloride met...

Embodiment 2

[0039]Weigh 200 parts of sodium carboxymethylcellulose and dissolve it with 20 times the volume of distilled water, then weigh 200 parts of periodic acid and dissolve it with 10 times the volume of distilled water. Under the condition of about 35°C, sodium carboxymethylcellulose solution and sodium periodate solution are simultaneously added to the reactor equipped with stirring device and temperature testing device, and the pH of the reaction system is adjusted to 3.0 with sulfuric acid. After reacting for about 4hrs, pour the reaction liquid into the solution storage, add 3 times the volume of acetone for precipitation, filter and separate after sufficient precipitation, wash the precipitate alternately with distilled water and acetone until no iodate is detected in the washing liquid, and then dry , Crush to obtain dialdehyde carboxymethyl cellulose. The aldehyde group content of the dialdehyde carboxymethyl cellulose is determined by the hydroxylamine hydrochloride method,...

Embodiment 3

[0041] Weigh 200 parts of sodium carboxymethylcellulose and dissolve with 20 times the volume of distilled water, then weigh 180 parts of sodium periodate and dissolve with 10 times the volume of distilled water. Under the condition of about 45°C, sodium carboxymethylcellulose solution and sodium periodate solution are simultaneously added to the reactor equipped with stirring device and temperature testing device, and the pH of the reaction system is adjusted to 3.0 with sulfuric acid. After reacting for about 4hrs, pour the reaction solution into the solution storage, add 2.5 times the volume of absolute ethanol for precipitation, filter and separate after sufficient precipitation, and alternately wash the precipitate with distilled water and acetone until no iodate component is detected in the washing solution. Then dry and pulverize to obtain dialdehyde carboxymethyl cellulose. The aldehyde group content of the dialdehyde carboxymethyl cellulose was determined by the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com