Method for producing active yeast cell derivative

A production method and technology of derivatives, applied in the field of production of live yeast cell derivatives, can solve the problems of high cost, moisturizing, anti-aging effect to be improved, and great difficulty, and achieve low production cost, shortened production cycle, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

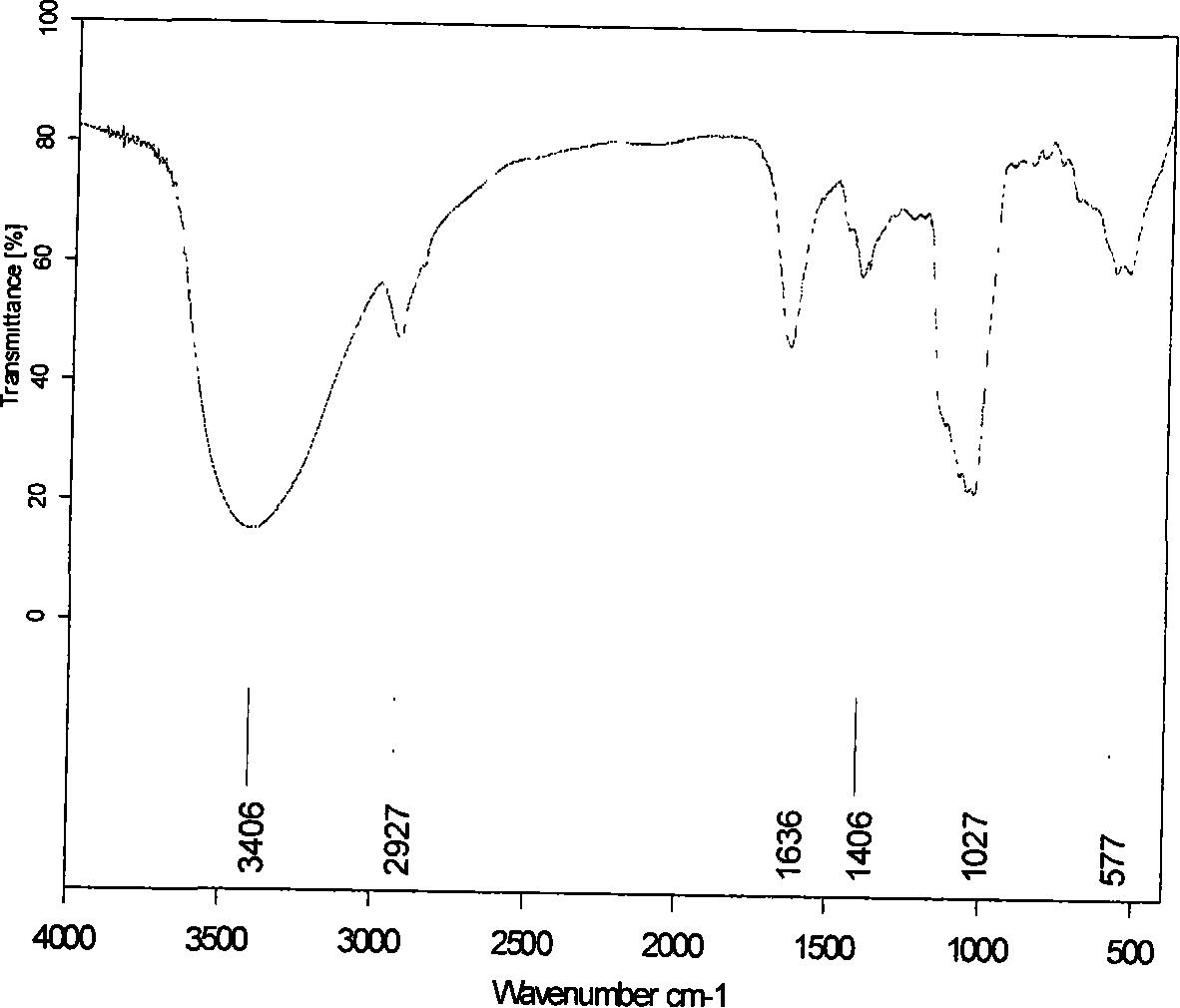

Image

Examples

Embodiment 1

[0024] A method for producing live yeast cell derivatives (LYCD), comprising the steps of:

[0025] (1). Strain selection: use microbial live yeast as the strain;

[0026] (2). Preparation of yeast culture medium: using wort juice 10 0 Brix is used as the slant medium, and YEPD medium is used as the liquid medium. The yeast stored in the wort slant medium is transferred to the liquid medium, and cultured at 28°C until the logarithmic phase for 12 hours to prepare the yeast culture solution ;

[0027] (3).Extreme high temperature stimulation: the adaptive temperature of the yeast culture medium was changed to a high temperature of 35°C for 30 minutes, and the yeast culture medium was at a high temperature of 35°C in the early, middle and late logarithmic stages;

[0028] (4). Cell collection: use a refrigerated centrifuge to centrifuge the yeast culture solution after high temperature stress at 4000 rpm for 10 minutes, and collect yeast cells;

[0029] (5). Thalline cell w...

Embodiment 2

[0048] A method for producing live yeast cell derivatives (LYCD), comprising the steps of:

[0049] (1). Strain selection: use microbial live yeast as the strain;

[0050] (2). Preparation of yeast culture medium: using wort juice 12 0 Brix is used as the slant medium, and YEPD medium is used as the liquid medium. The yeast stored in the wort slant medium is transferred to the liquid medium, and cultured at 30°C until the logarithmic phase for 8 hours to prepare the yeast culture solution ;

[0051] (3).Extreme high temperature stimulation: the adaptive temperature of the yeast culture medium was changed to a high temperature of 37°C for 28 minutes, and the yeast culture medium was at a high temperature of 37°C in the early, middle and late logarithmic stages;

[0052](4). Cell collection: use a refrigerated centrifuge to centrifuge the yeast culture solution after high temperature stress at 4000 rpm for 8 minutes, and collect the yeast cells;

[0053] (5). Thalline cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com