Molded rubber clad plate and method for preparing same

A composite board, rubber technology, applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problem of not considering the static bending strength and elastic modulus of the product, achieve good protection and improve performance , the effect of foot comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Table 1

[0033] (1) Mix 100 parts of reclaimed rubber shown in Table 1 with its ingredients, and knead with a two-roll rubber mill to obtain a hard rubber mix.

[0034] (2) 70 parts of natural rubber and 30 parts of EPDM rubber shown in Table 1 were mixed with their ingredients, and mixed by a double-roller rubber mixer to obtain a soft rubber compound.

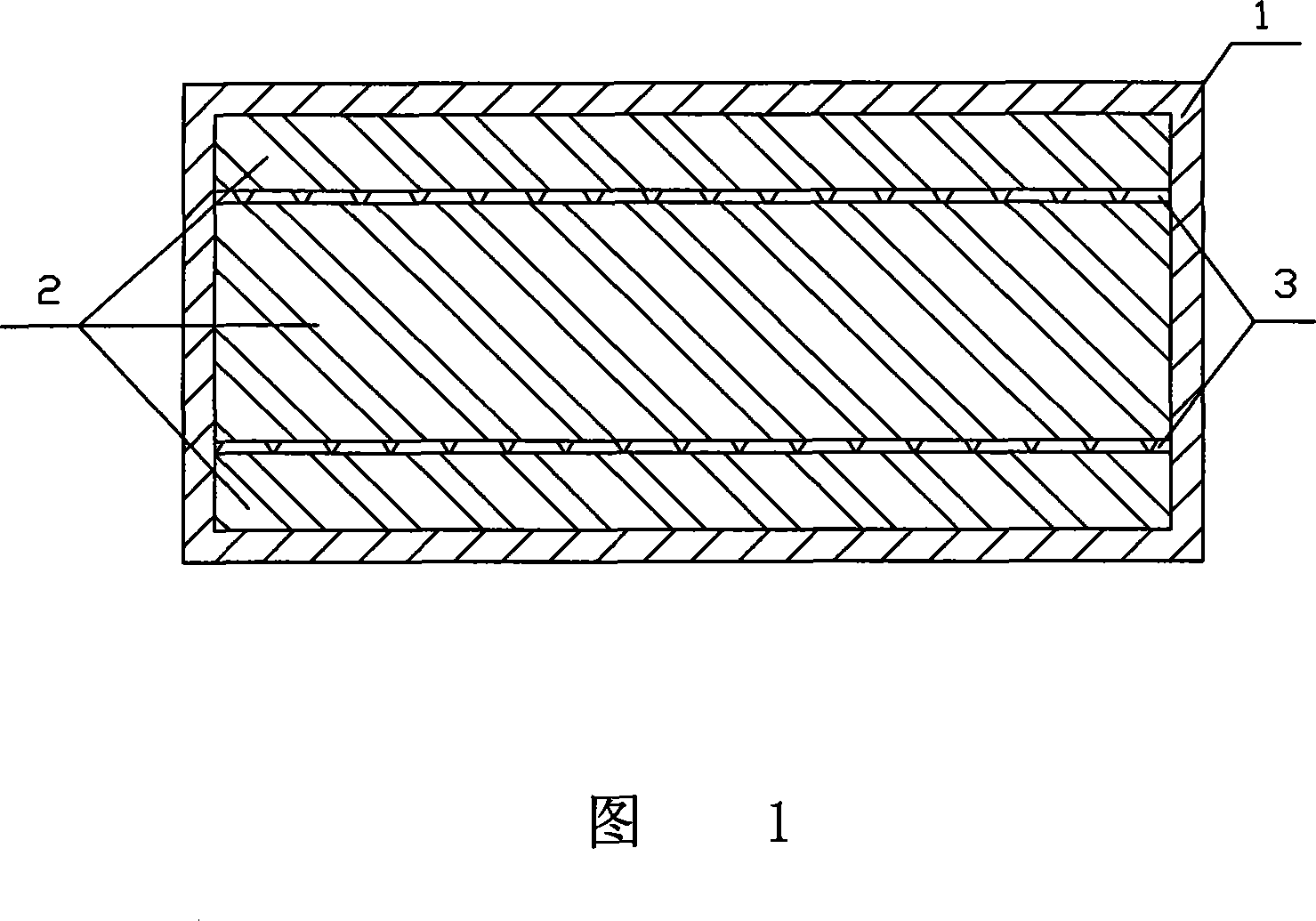

[0035] (3) Coat the 2mm thick soft rubber compound on the surface of the 40mm thick hard rubber compound, then place it in the mold, and send it to a flat vulcanizer for co-vulcanization. The vulcanization temperature is 160°C, the pressure is 25MPa, and the time For 35 minutes, a molded rubber composite panel was prepared.

[0036] The molded rubber composite plate made by the above-mentioned embodiment is measured with a material universal testing machine, and the static bending strength recorded by the GB / T 17657-1999 standard is 62.7MPa, and the static elastic modulus is 7150MPa; a...

Embodiment 2

[0039] Table 2

[0040] (1) Mix 100 parts of reclaimed rubber shown in Table 2 with its ingredients, and knead with a two-roll rubber mixer to obtain a hard rubber mix.

[0041] (2) 70 parts of natural rubber and 30 parts of EPDM rubber shown in Table 2 were mixed with their ingredients, and mixed by a double-roller rubber mixer to obtain a soft rubber compound.

[0042] (3) Cover the surface of 60mm thick hard rubber compound with 2mm thick soft rubber compound, then place it in the mold, and send it to a flat vulcanizer for co-vulcanization. The curing temperature is 160°C, the pressure is 30MPa, and the time is For 30 minutes, a molded rubber composite panel was prepared.

[0043] The molded rubber composite plate made by the above-mentioned embodiment is measured with a material universal testing machine, and the static bending strength of hard rubber recorded according to the GB / T 17657-1999 standard is 77.5MPa, and the static elastic modul...

Embodiment 3

[0046] table 3

[0047] (1) Mix 100 parts of reclaimed rubber shown in Table 3 with its ingredients, and knead with a two-roll rubber mill to obtain a hard rubber mix.

[0048] (2) 70 parts of natural rubber and 30 parts of EPDM rubber shown in Table 3 were mixed with their ingredients, and mixed by a two-roller rubber mixer to obtain a soft rubber compound.

[0049] (3) Coat 1.5mm thick soft rubber compound on the surface of 30mm thick hard rubber compound, then place it in the mold, and send it to a flat vulcanizer for co-vulcanization. The vulcanization temperature is 160°C, the pressure is 35MPa, The time is 35 minutes, and the molded rubber composite board is prepared.

[0050] The molded rubber composite plate made by the above-mentioned embodiment is measured with a material universal testing machine, and the static bending strength of hard rubber recorded according to the GB / T 17657-1999 standard is 43.7MPa, and the static elastic modulus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com