Method for producing 1-p-methylphenyl ethylamine

A technology of tolylethylamine and p-methylacetophenone, applied in the production of chemical intermediates and the production of intermediate 1-p-tolylethylamine, which can solve the problems of harsh ultra-high pressure conditions, high equipment requirements, and poor safety , to achieve the effect of cheap raw materials, good safety, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

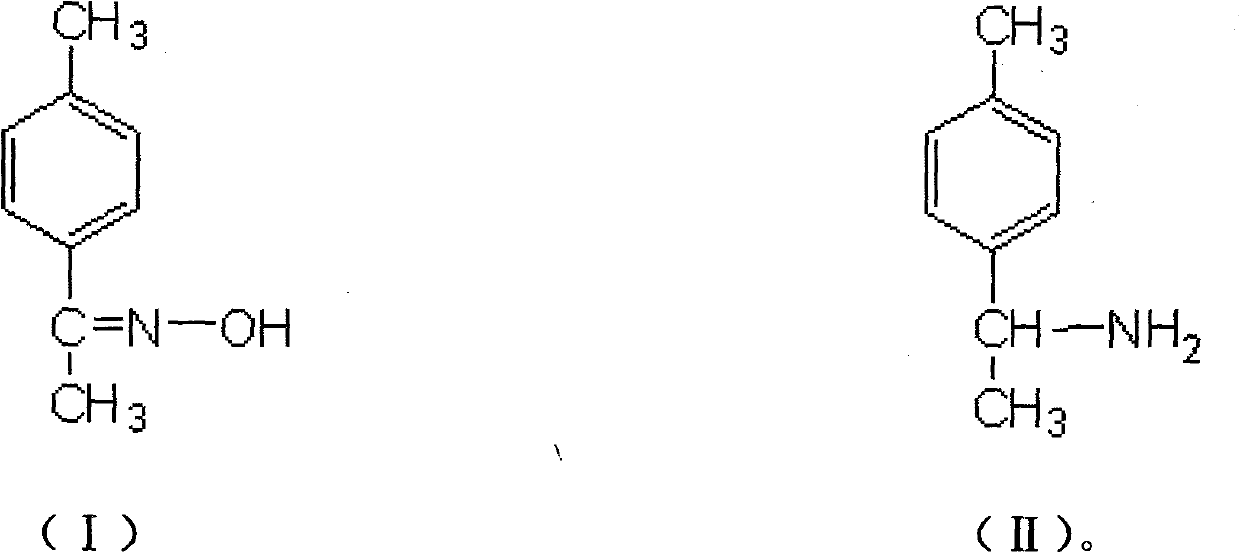

[0033] In the 500ml there-necked flask equipped with stirrer, thermometer, reflux cooler, drop into raw material 44.5g p-methyl acetophenone, 27.6 gram hydroxylamine hydrochloride, mixed solvent 140g ethanol and 10g water. Add 24g of neutralizing agent sodium hydroxide under the condition of stirring, and finish the dosage in 5 times. Cool to room temperature, add 320ml of water, cool to below 5°C with stirring and filter quickly, and dry the filter cake at about 50°C to obtain the oximate with a yield greater than 95%.

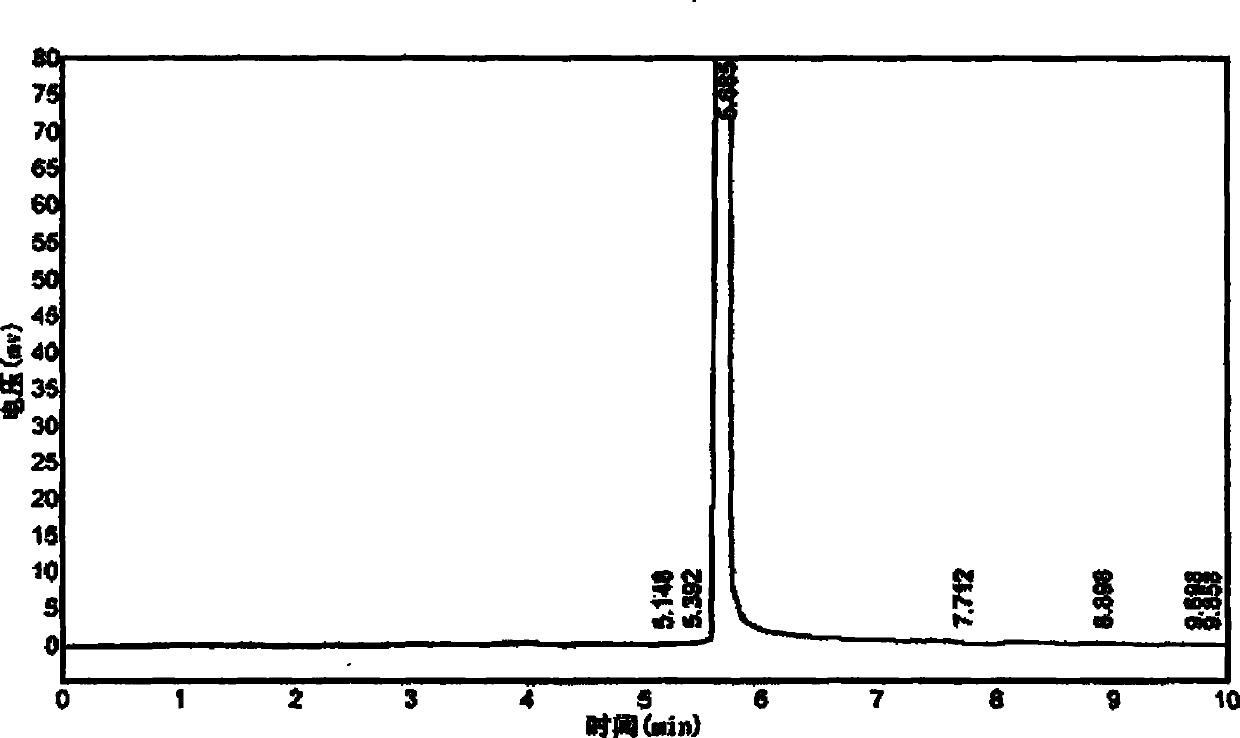

[0034] Put the oximide prepared above, 500ml of anhydrous methanol and 4gW-2 Raney nickel into the pressure vessel, and then pass hydrogen to maintain the pressure of the reaction system at 1.2-1.3Mpa, the temperature is 70°C, and the catalytic hydrogenation reaction time is about After 4 hours, the end point was detected by TLC, and a catalytic hydrogenation material containing crude 1-p-tolylethylamine was obtained after the reaction.

[0035] The catalyti...

Embodiment 2

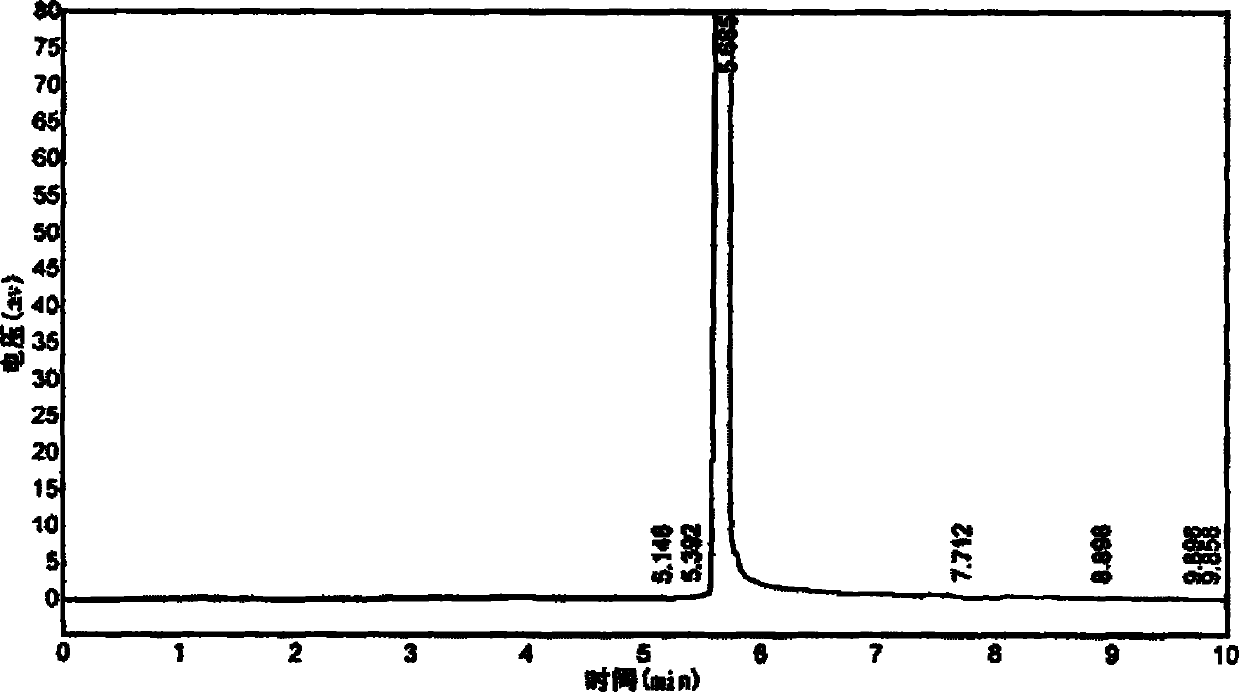

[0037] The device used for the oximation reaction is the same as in Example 1, and will not be described in detail; 89g of p-methylacetophenone, 52.1g of hydroxylamine sulfate, 192g of ethanol and 60g of water as the mixed solvent are put into the raw material. Add 46g of neutralizing agent sodium hydroxide under the condition of stirring, and finish the dosage in 6 times. Cool to room temperature, add 480ml of water, cool to below 5°C with stirring and quickly filter, and quickly dry the filter cake at about 50°C to obtain the oximide with a yield greater than 95%.

[0038]Put the oximide prepared above, 600ml of anhydrous methanol and 2g of platinum oxide into the pressure vessel, and then pass hydrogen to maintain the pressure of the reaction system at 1.4-1.6Mpa, the temperature is 60°C, the catalytic hydrogenation reaction time is about 5 hours, TLC The end point is detected, and the catalytic hydrogenation material containing the crude product of 1-p-tolylethylamine is o...

Embodiment 3

[0041] The device used for the oximation reaction is the same as in Example 1, and will not be described in detail; 92g of p-methylacetophenone, 54g of hydroxylamine hydrochloride, 185g of ethanol and 55g of water as a mixed solvent are put into the raw materials. Put in 48g of neutralizing agent sodium hydroxide under the condition of stirring, divide into 5 times, control the temperature at 40-45°C, heat to 70°C and reflux for 6 minutes after the throwing, after the reaction, distill and recover ethanol under normal pressure conditions, Cool to room temperature, add 500ml of water, cool to below 5°C with stirring, and quickly filter, and dry the filter cake at about 50°C to obtain the oximate, with a yield of up to 90%.

[0042] Put the oximide prepared above, 800ml of anhydrous methanol and 3g of palladium carbon into the pressure vessel, and then pass hydrogen to maintain the pressure of the reaction system at 1.6-1.8Mpa, the temperature is 80°C, the catalytic hydrogenation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com