Process for producing alkyl phosphonic acid

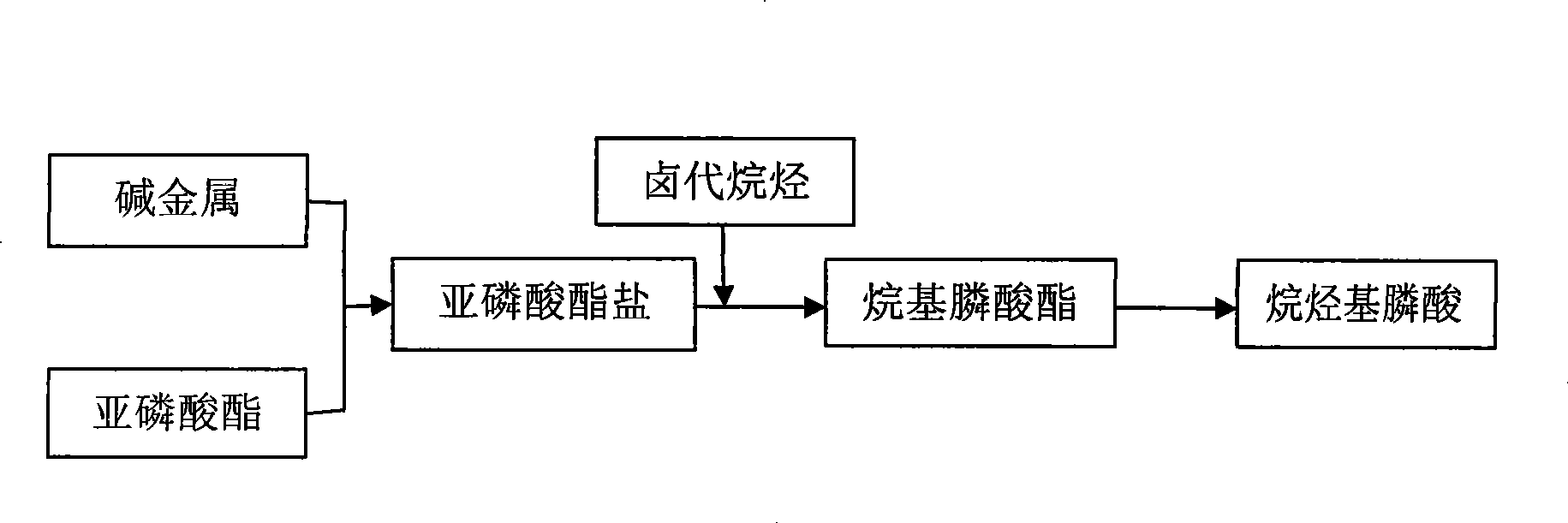

A technology for alkane phosphonic acid and alkane phosphonic acid ester, which is applied in the field of preparing alkane phosphonic acid, can solve the problems of low product purity, difficult separation and purification, and many by-products, and achieves simple process flow, high purity, and high yield. rate stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Lithium 175g (25mol) is joined in the 30L toluene of 110 ℃, reflux sanding, dropwise add methyl propyl phosphite 3.46kg (25mol), continue to stir and reflux for 6 hours, dropwise add chloroethane 1.94kg ( 30mol), reflux reaction for 18 hours, lowering the temperature, filtering and reclaiming a little lithium remaining, the filtrate first reclaims toluene under normal pressure, then distills under reduced pressure to obtain methylpropyl ethylphosphonate, adds glacial acetic acid to methylpropyl ethylphosphonate, Hydrolyze until the reaction is complete, dehydrate to obtain the crude product, and recrystallize from toluene to obtain 1782 g of white flaky solid ethylphosphonic acid with a yield of 64.8% and a purity of 96.3%.

Embodiment 2

[0022] Example 2: Add 575 g (25 mol) of sodium to 32 L of xylene at 145 ° C, reflux to sand, add 2.76 kg (25 mol) of dimethyl phosphite dropwise, continue to stir and reflux for 12 hours, and add 3.27 kg of bromoethane dropwise (30mol), reflux reaction for 18 hours, lower the temperature, filter and recover a little residual sodium, the filtrate first recovers xylene under normal pressure, then distill under reduced pressure to obtain dimethyl ethylphosphonate, add hydrogen to dimethyl ethylphosphonate Sodium oxide was hydrolyzed until the reaction was complete, and the crude product was obtained by dehydration, which was recrystallized from toluene to obtain 1869 g of white flaky solid ethylphosphonic acid with a yield of 67.9% and a purity of 95.6%.

Embodiment 3

[0023] Example 3: Add 978g (25mol) of potassium to 30L of toluene at 130°C, reflux to sand, add 3.46kg (25mol) of methyl propyl phosphite dropwise, continue to stir and reflux for 6 hours, and add 2.36kg of 1-chloropropane dropwise (30mol), reflux reaction for 18 hours, lower the temperature, filter and recover a little lithium remaining, the filtrate first recovers toluene under normal pressure, then distills under reduced pressure to obtain methylpropyl ethylphosphonate, and adds glacial acetic acid to methylpropyl ethylphosphonate , hydrolyzed until the reaction was complete, and dehydrated to obtain a crude product, which was recrystallized from toluene to obtain 2010 g of white flaky solid propylphosphonic acid with a yield of 64.8% and a purity of 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com