Method and equipment for manufacturing fire engine hose

A manufacturing method and technology for manufacturing equipment, which are applied in the field of plastic processing, can solve the problems that affect the wide-scale promotion and application of products, poor compression resistance of water hoses, and slow molding process, etc., and achieve low production cost, good molding effect, and cooling speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

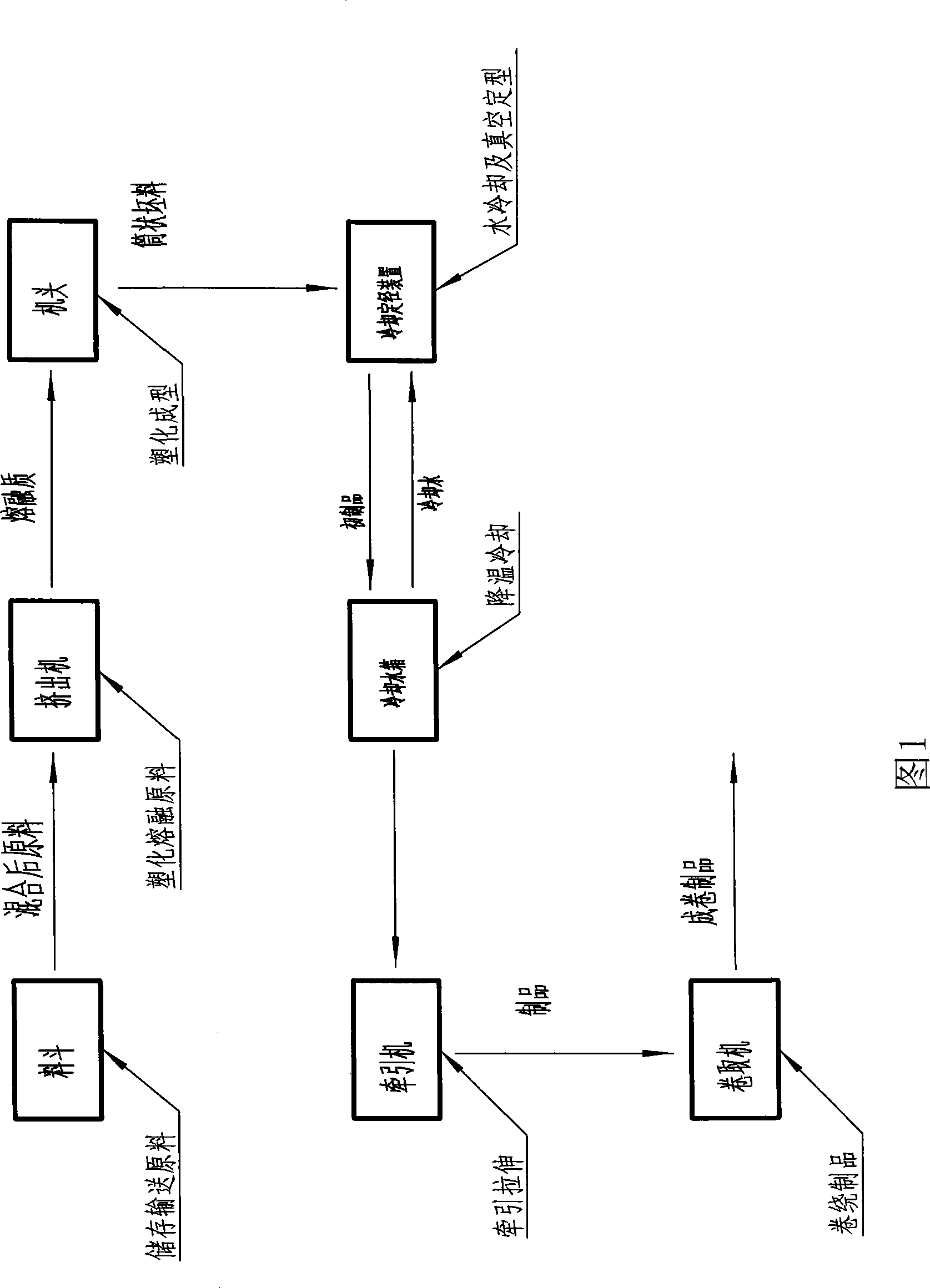

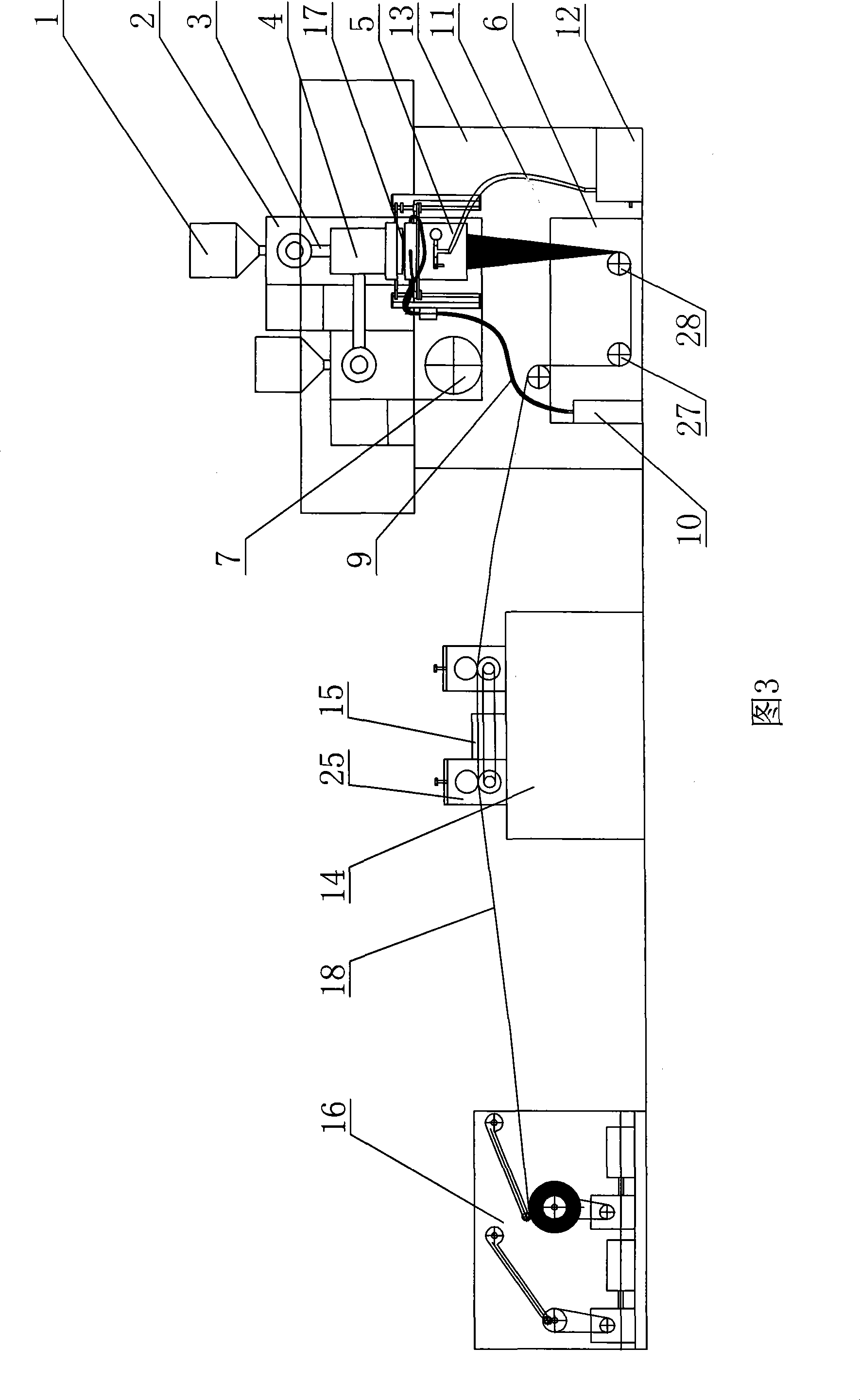

[0014] In the manufacturing method of water hose of the present invention, the required raw material of water hose is the plastic raw material such as PP resin, PE resin or PE resin reclaimed material, and its manufacturing process is:

[0015] (1) Fully mix the selected raw materials, color masterbatch and ingredients and put them into a container. The container can be a device such as a hopper.

[0016] (2) Put the mixed raw materials in the container into the extrusion device, the extrusion device operates continuously, plasticizes and melts the mixed raw materials to form a melt, and the extrusion device continuously transfers the melt from the gap of the forming mold Extrusion to form a continuous cylindrical billet;

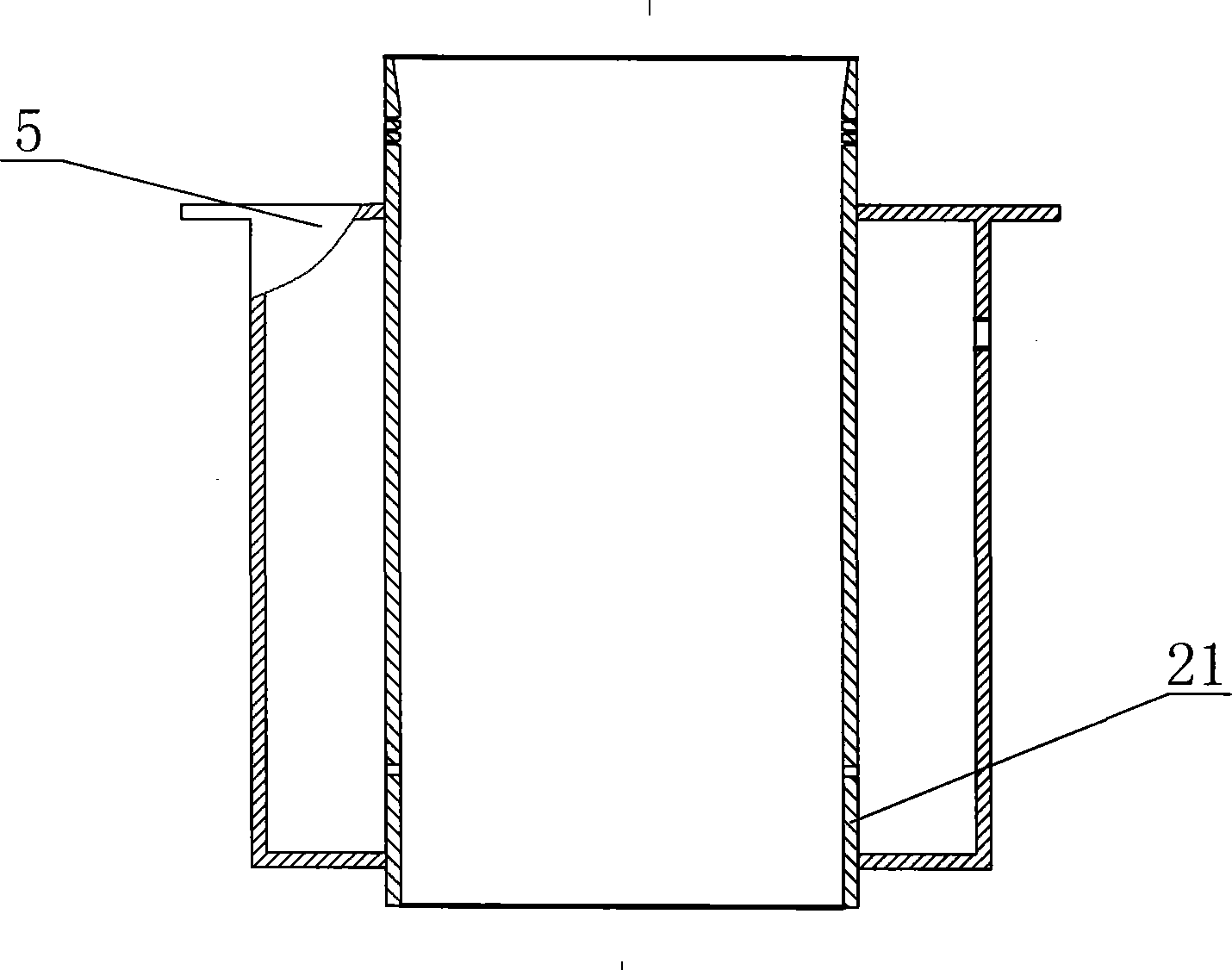

[0017] (3) The tractor pulls one end of the cylindrical billet, so that the cylindrical billet walks evenly into the cooling and sizing device, and the cooling water cools the wall of the cylindrical billet. The cooling time is the time for the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com