Straight pipe double-ended automatic non-bur cutter device

A cutting device, burr-free technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc. The effect of continuous production, avoiding industrial accidents and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

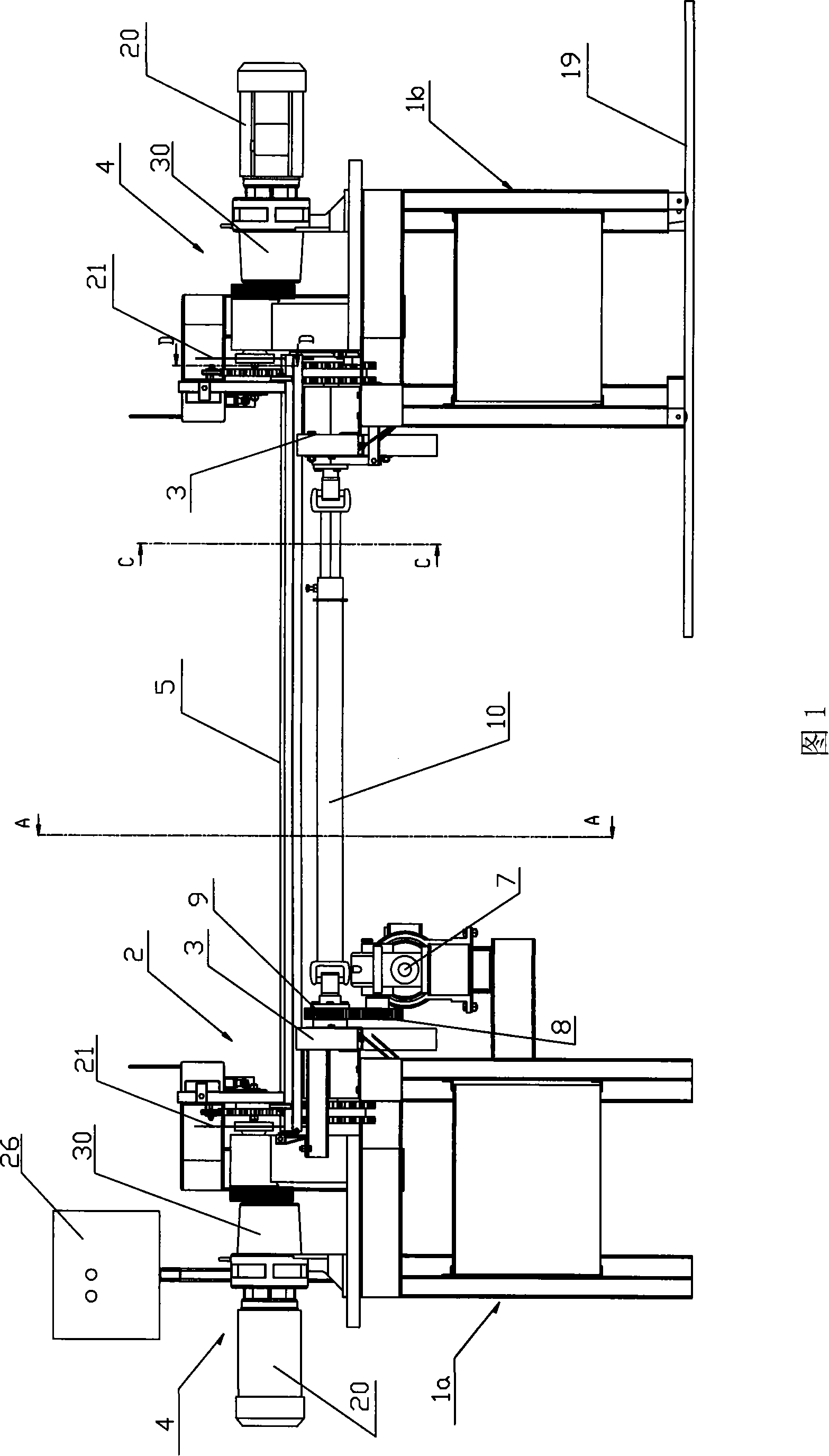

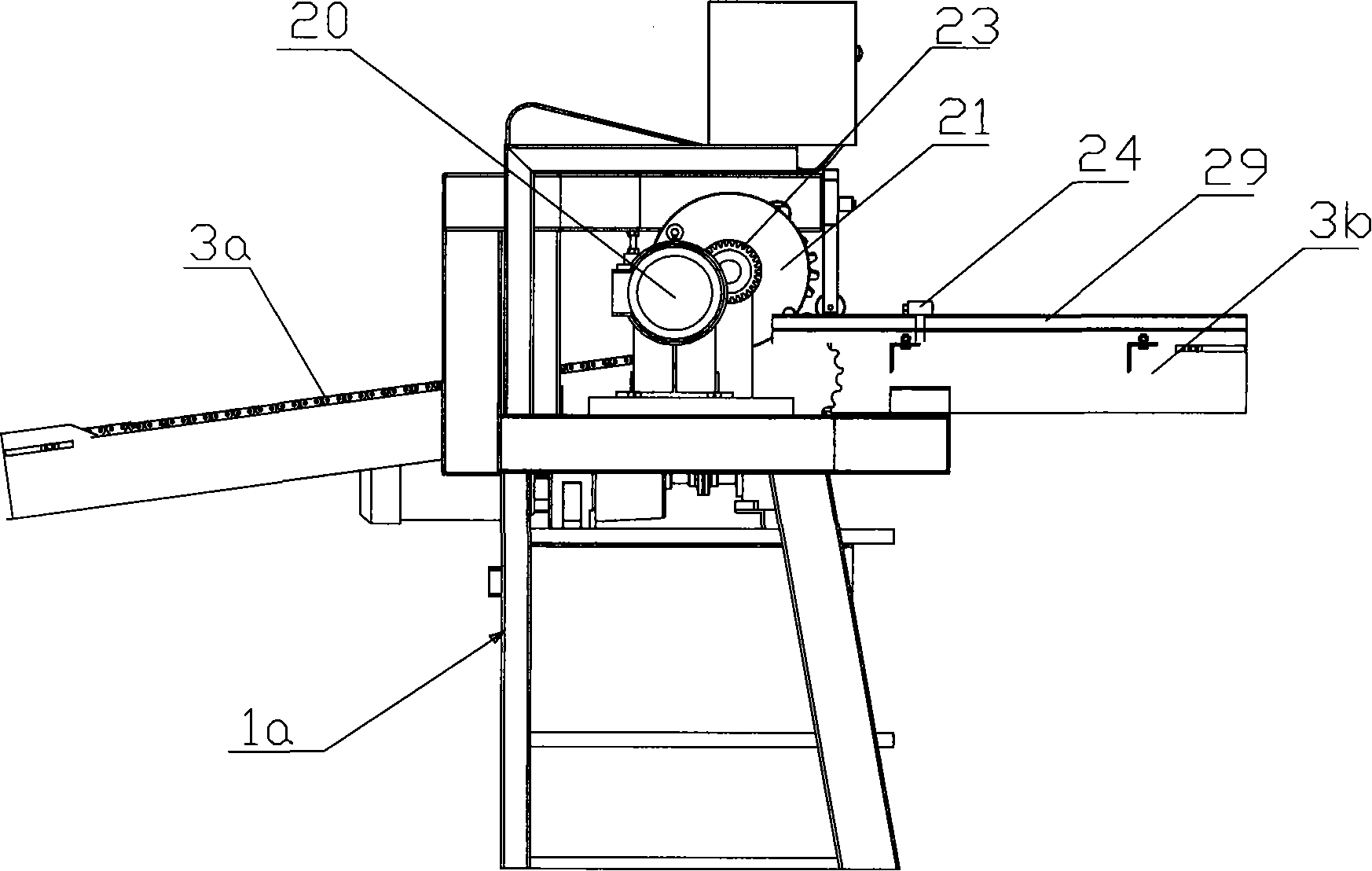

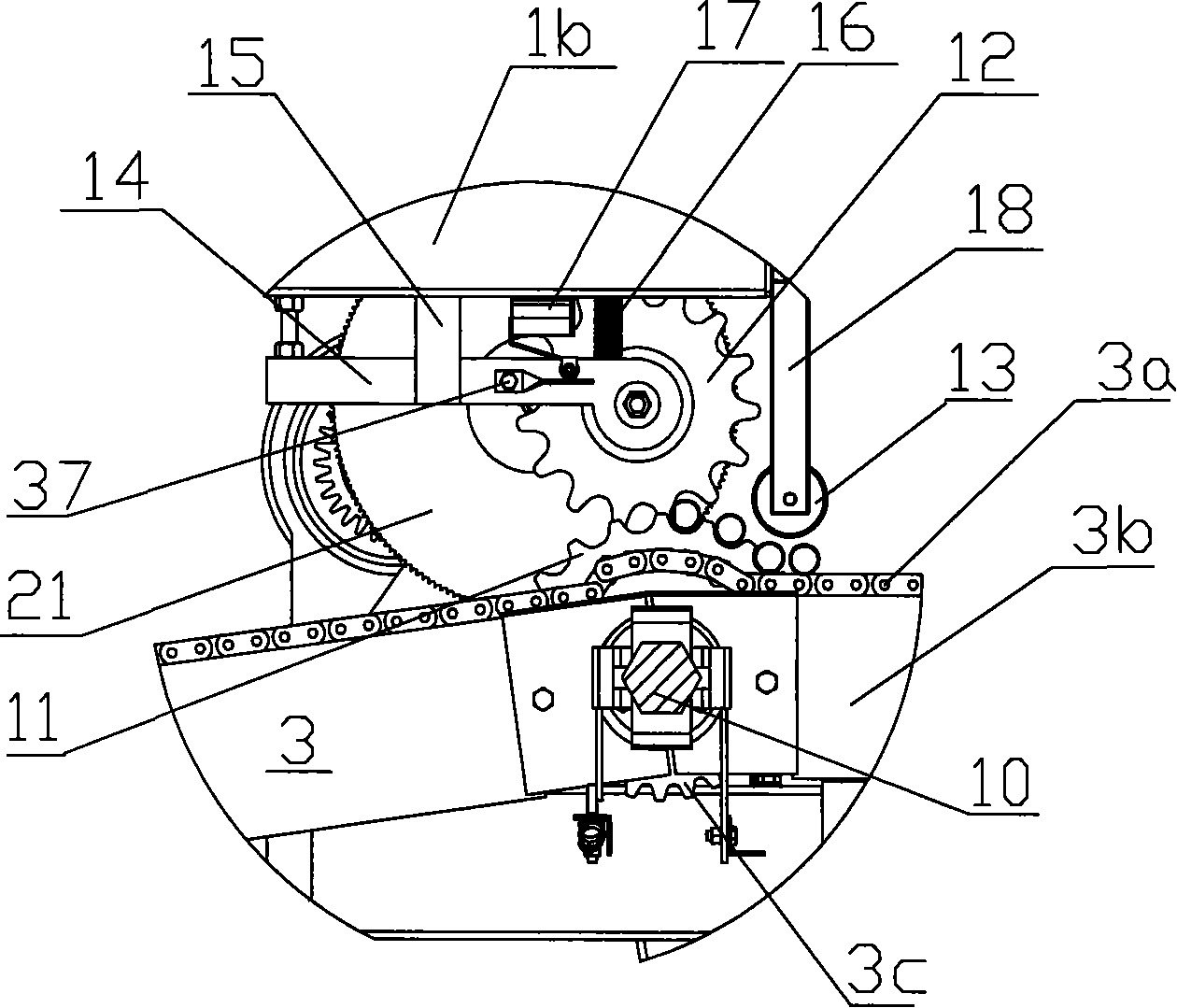

[0045] Specific embodiments are given below in conjunction with the accompanying drawings to further illustrate how the present invention is realized.

[0046] Figure 1, figure 2 , shown in Fig. 3, straight pipe double-headed automatic burr-free cutting device of the present invention includes the first support 1a and the second support 1b that are respectively arranged on both sides correspondingly, the first support 1a and the second support 1b that are positioned at both sides The bracket 1b is respectively provided with a clamping structure 2 for fixing the two ends of the cut tube, and a tube feeding guide rail 3 which is linked with the clamping structure 2 on both sides and used to support and transport the cut tube 5; On the first bracket 1a and the second bracket 1b and on the outside of the tube clamping structure 2 and the tube feeding guide rail 3, a tube cutting structure 4 is correspondingly provided.

[0047] Figure 1, Figure 4 , Figure 5 , Figure 6 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com