Rotary type pressure-variable adsorption gas separating method

A technology of pressure swing adsorption and gas separation, which is applied in the separation of mixed gases and the field of rotary pressure swing adsorption gas separation. It can solve the problems of large amount of adsorbent, low production capacity, cumbersome operation, etc., and achieve convenient operation and high equipment production capacity. High, fast absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 air separation prepares oxygen and nitrogen

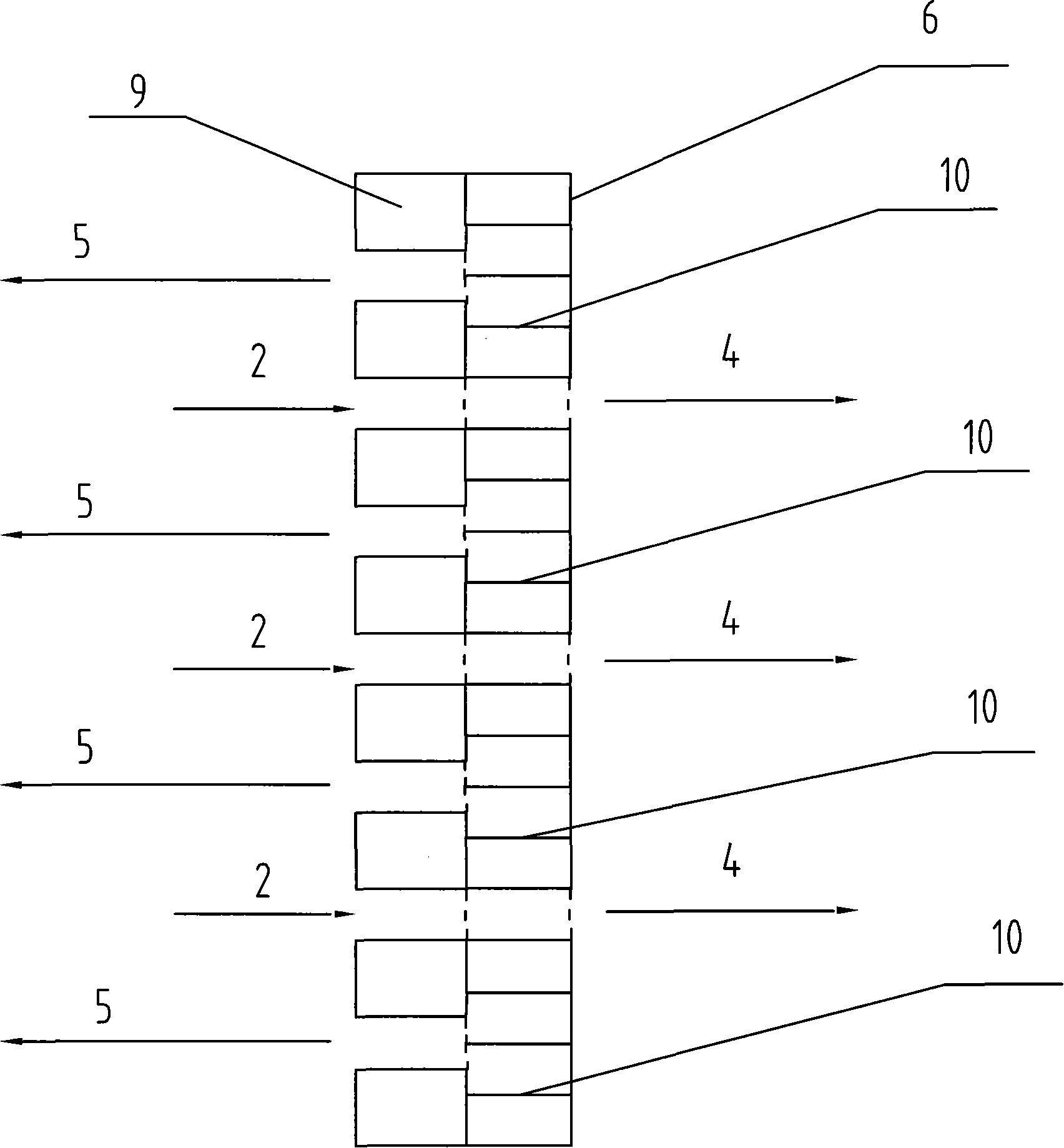

[0032] The rotary pressure swing adsorption gas separator 3 carries six adsorbent components divided by the adsorbent partition 10; the adsorbent components are all filled with 5A molecular sieves. Including the following process steps:

[0033] a. Air pressurized distribution; the mixed gas compressor 1 passes through the gas distributor matched with the rotary pressure swing adsorption gas separator 3, and sends air into the adsorbent assembly equipped with 5A molecular sieve;

[0034] b. High-pressure adsorption: air enters the adsorbent assembly located in the high-pressure adsorption area, nitrogen is absorbed by the adsorbent, oxygen passes through the adsorbent assembly, and is collected after leaving the rotary pressure swing adsorption gas separator 3;

[0035] c. Low-pressure desorption and regeneration: The adsorbent components after high-pressure adsorption are rotated into the low-pressure desorpti...

Embodiment 2

[0037] Embodiment 2 air separation prepares oxygen and nitrogen

[0038] According to the method and steps of Example 1, the rotary pressure swing adsorption gas separator 3 carries 4 adsorbent assemblies divided by the adsorbent partition 10; the adsorbent assemblies are filled with carbon molecular sieves.

Embodiment 3

[0039] Example 3 The decarburization section in the synthetic ammonia production process, the separation of carbon dioxide and synthetic ammonia raw material gas

[0040] According to the method and steps of Example 1, wherein the rotary pressure swing adsorption gas separator 3 carries two adsorbent modules, filled with X-type molecular sieves. Carbon dioxide is firstly adsorbed in the high-pressure adsorption zone, then enters the low-pressure desorption and regeneration zone to be desorbed, and then sent to the carbonization section to synthesize urea, and the rest of the synthetic ammonia raw material gas passes through the adsorbent component and enters the next process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com