Long-life high-performance screw drill transmission shaft bearing

A kind of screw drilling tool, high-performance technology, applied in the direction of shaft and bearing, rolling contact bearing, bearing in rotary motion, etc., can solve the problems of high contact pressure, small contact area, surface deformation, etc., to achieve strong field applicability, improve Manufacturing cost, simple shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

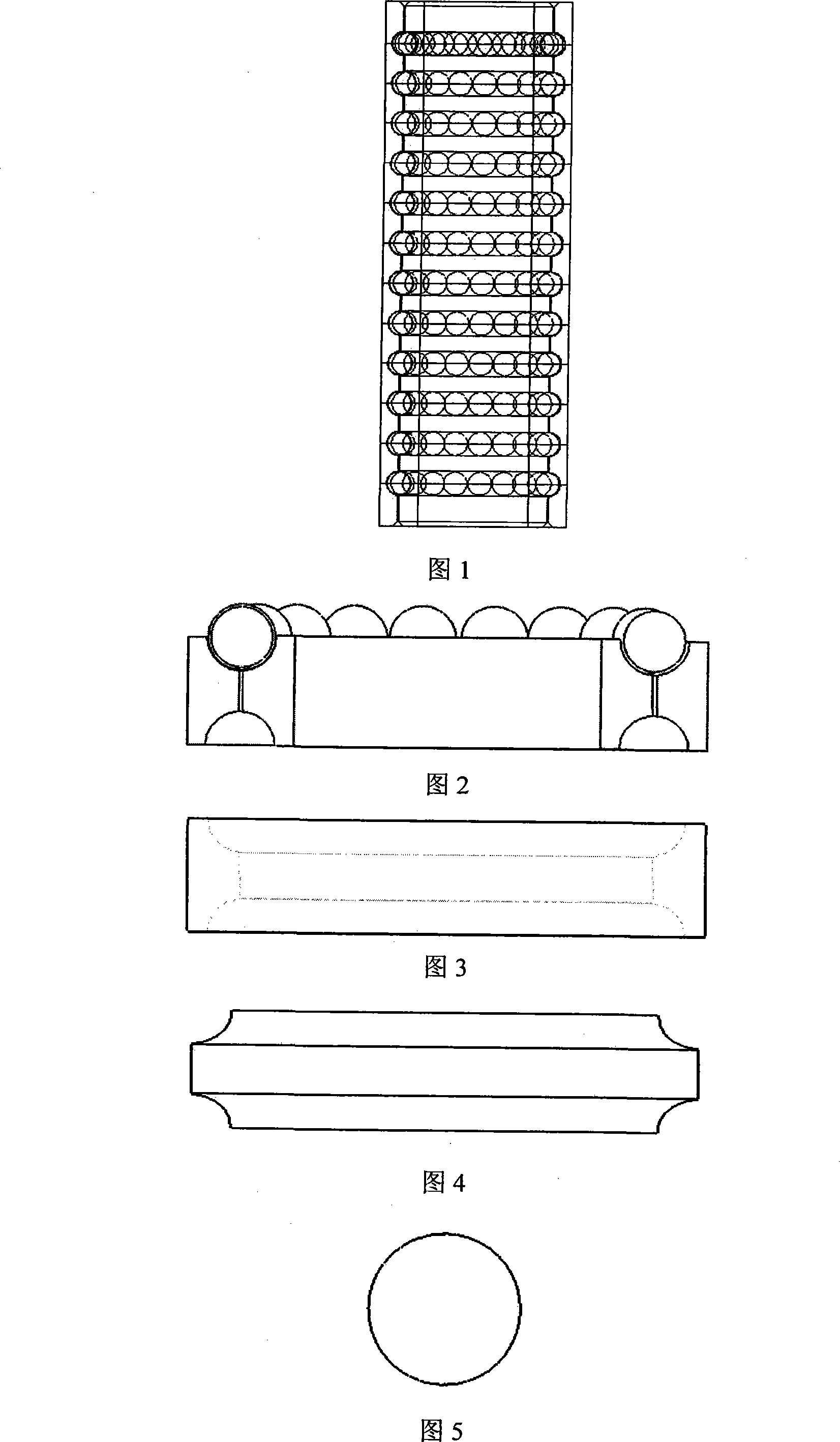

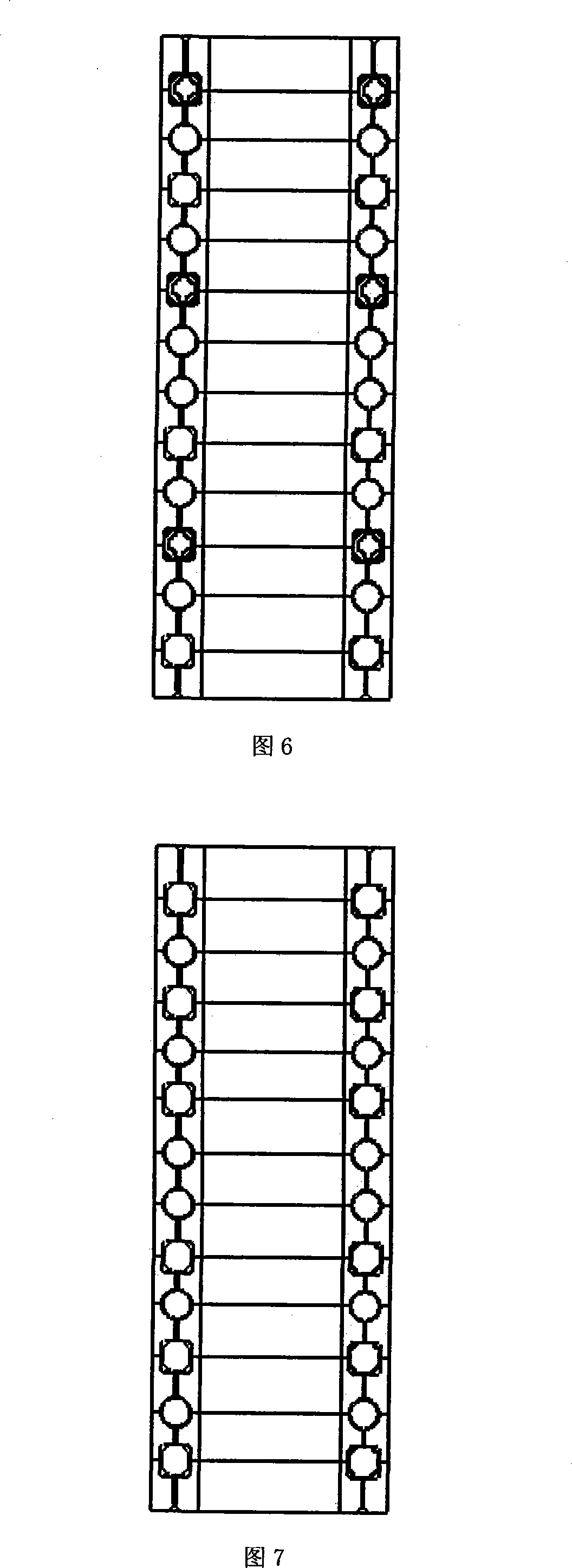

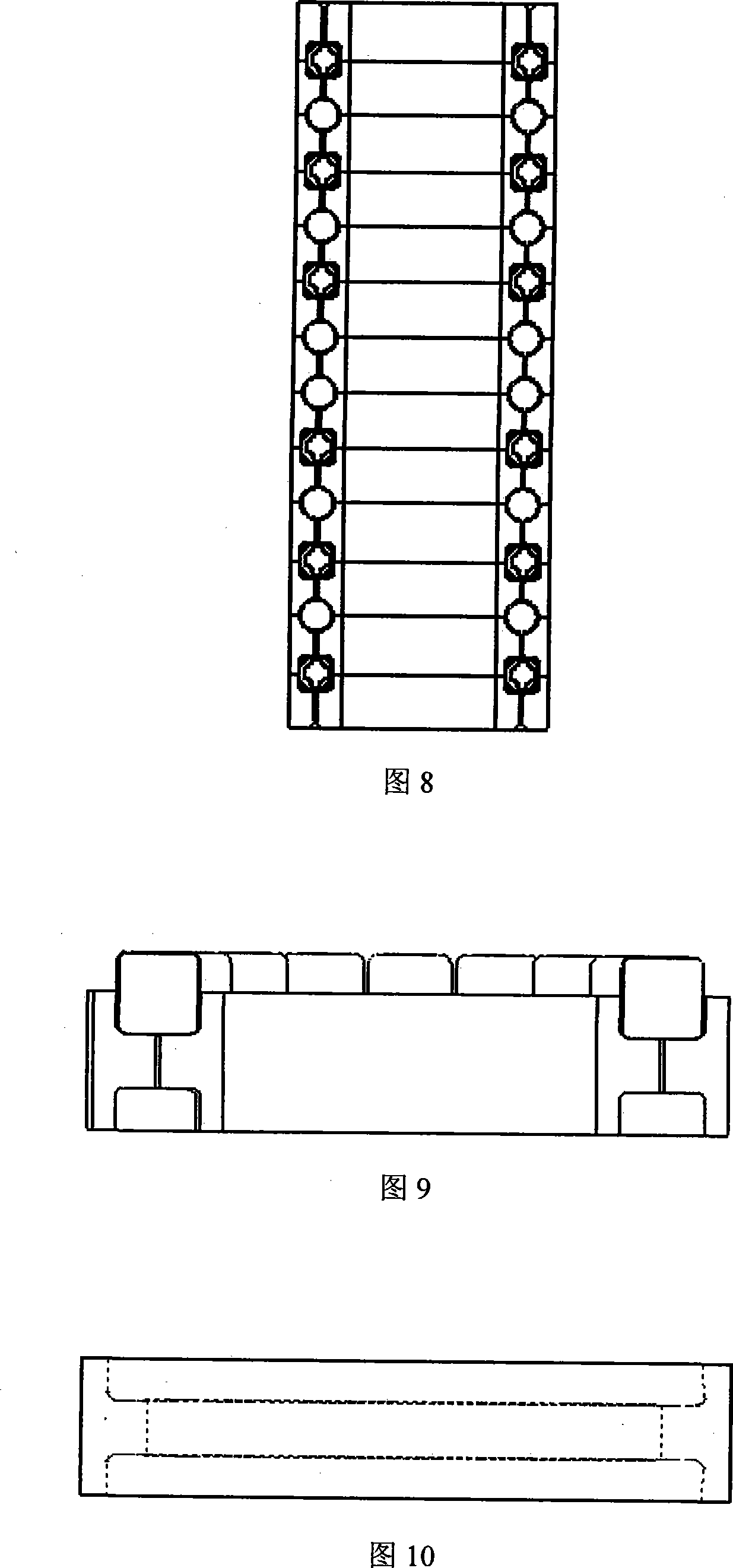

[0025] As shown in Figure 6, the first embodiment of a long-life and high-performance screw drilling tool drive shaft bearing of the present invention consists of a radial thrust ball bearing (Figure 2), a radial cylindrical roller bearing (Figure 9) and a centripetal double-round platform Roller bearings (Figure 13) are combined.

[0026] As shown in Fig. 7, the second embodiment of a long-life high-performance screw drilling drive shaft bearing of the present invention is composed of a radial thrust ball bearing (Fig. 2) and a radial cylindrical roller bearing (Fig. 9).

[0027] As shown in Fig. 8, the third embodiment of a long-life and high-performance screw drilling drive shaft bearing of the present invention is composed of a radial thrust ball bearing (Fig. 2) and a centripetal double-cylindrical roller bearing (Fig. 13).

[0028] The radial thrust ball bearing (Fig. 2) consists of a radial thrust ball bearing single outer ring (Fig. 3), a radial thrust ball bearing sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com