Drum washing and drying machine

A washing-drying machine, drum-type technology, which is applied to other washing machines, household dryers, washing machines with containers, etc., can solve the problems of inability to wet the folds of clothes, unable to fully dry clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Hereinafter, the best embodiments related to the drum-type washing and drying machine of the present invention will be described based on the drawings. In addition, the embodiments disclosed below are examples in all points, and should not be regarded as limiting content. The technical scope of the present invention is not the content disclosed in the embodiments, but is indicated by the description of the claims, and should be understood to include all changes within the meaning and scope equivalent to the claims.

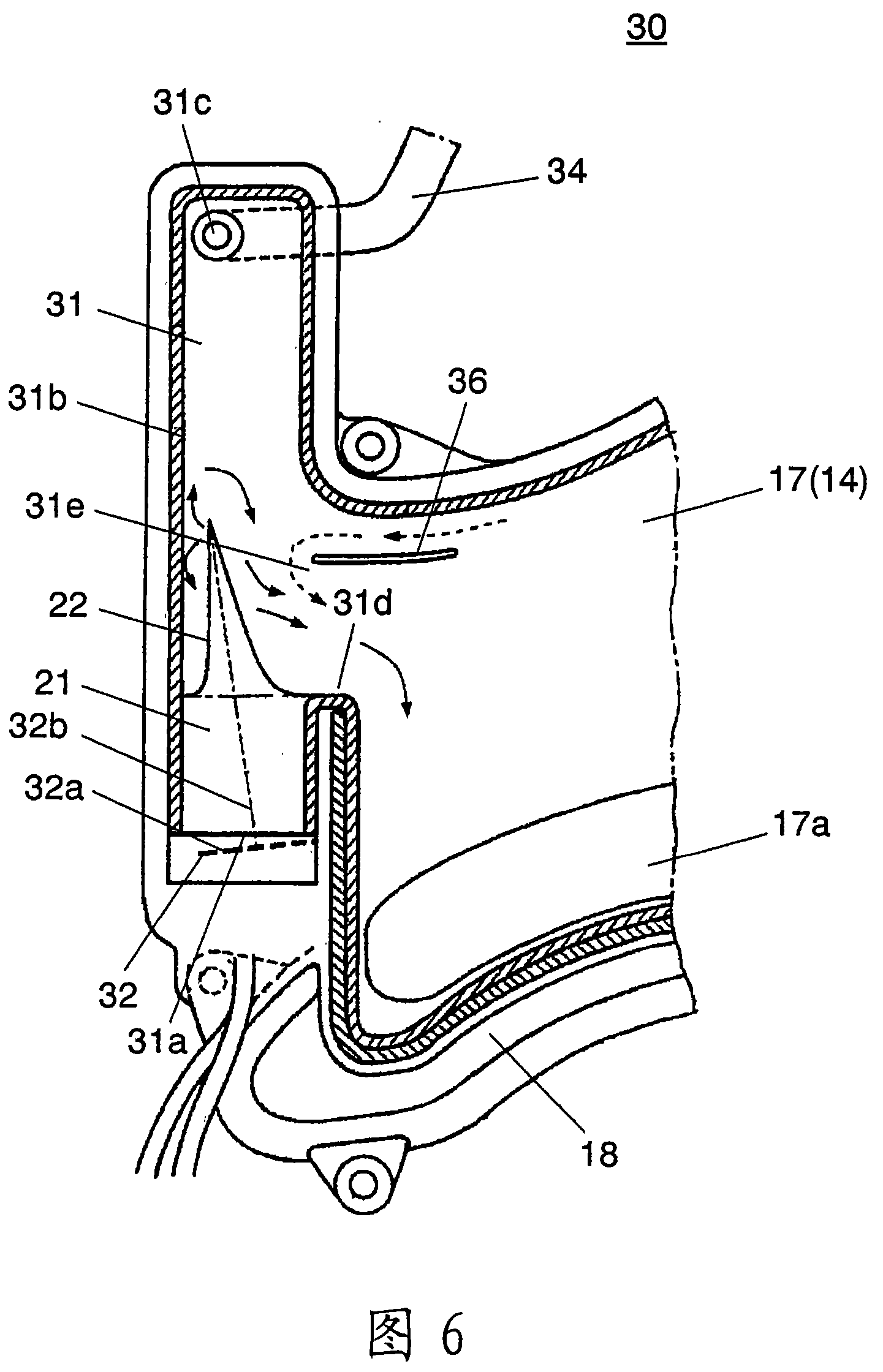

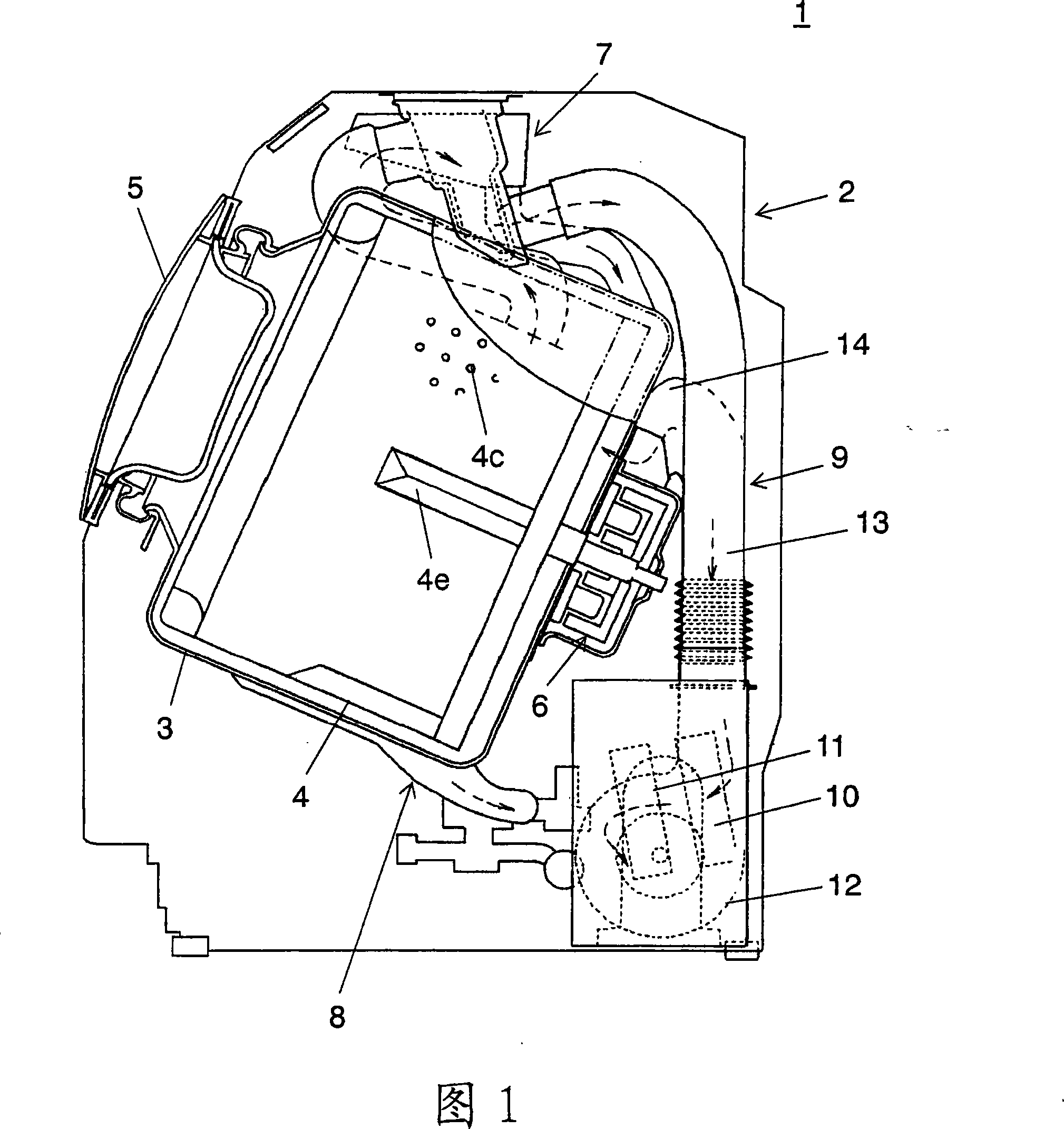

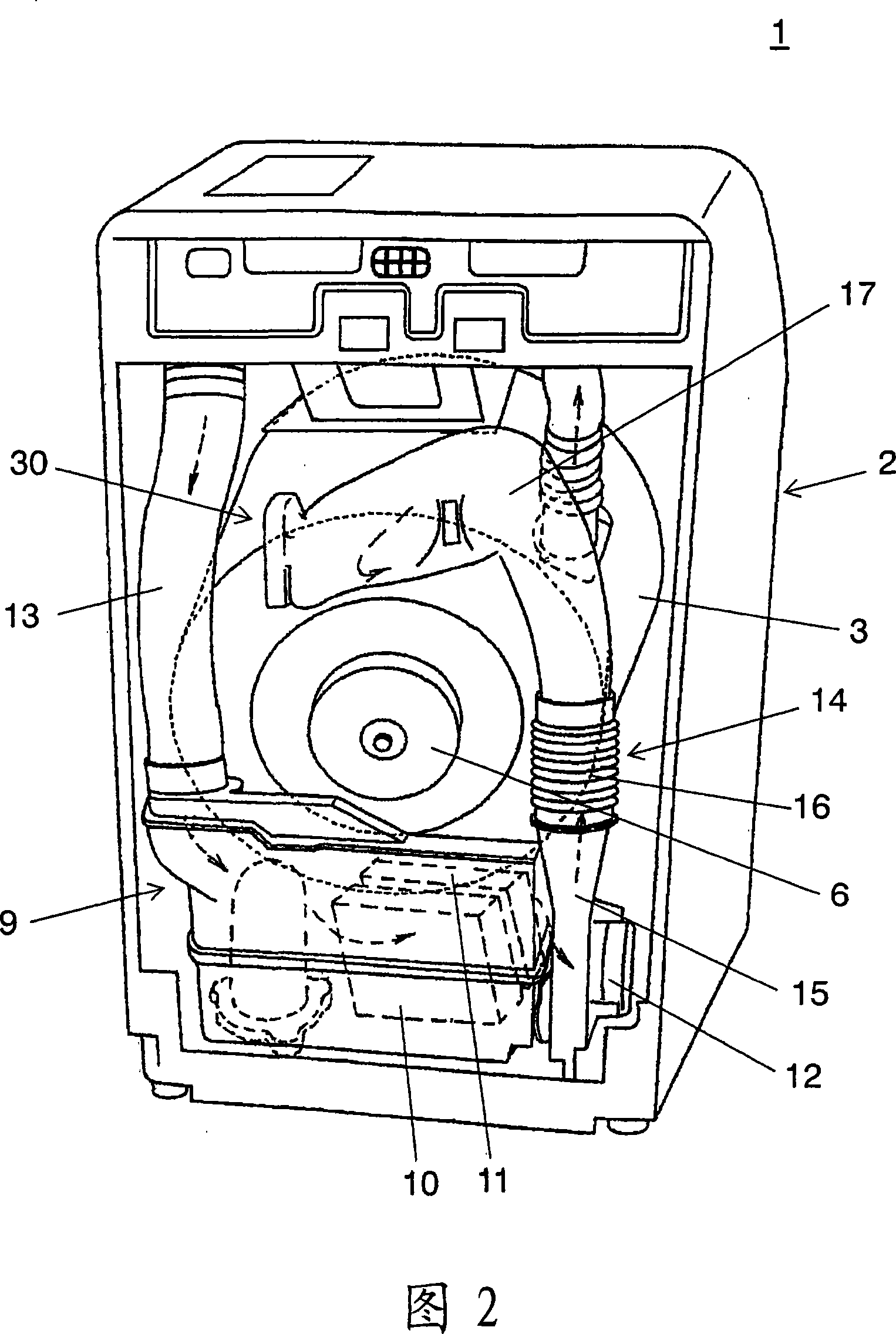

[0023] First, based on FIGS. 1 to 4, the structure and operation of a drum-type washing and drying machine having an atomizing unit according to an embodiment of the present invention will be described in detail. Fig. 1 is a side cross-sectional view for explaining the structure of a drum-type washer-dryer according to an embodiment of the present invention. Fig. 2 is a perspective view of the drum-type washer-dryer, viewed from the back side of the housing, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com