Method for one-section abstraction distillation separation cracking carbon 5-cut fraction

A technology of extractive distillation and extractive distillation tower, which is applied in the field of separating and cracking C5 fractions to produce polymer grade isoprene products, which can solve the problems of large solvent loss, difficult operation, and unsafety, and achieve easy operation and operation Simple, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

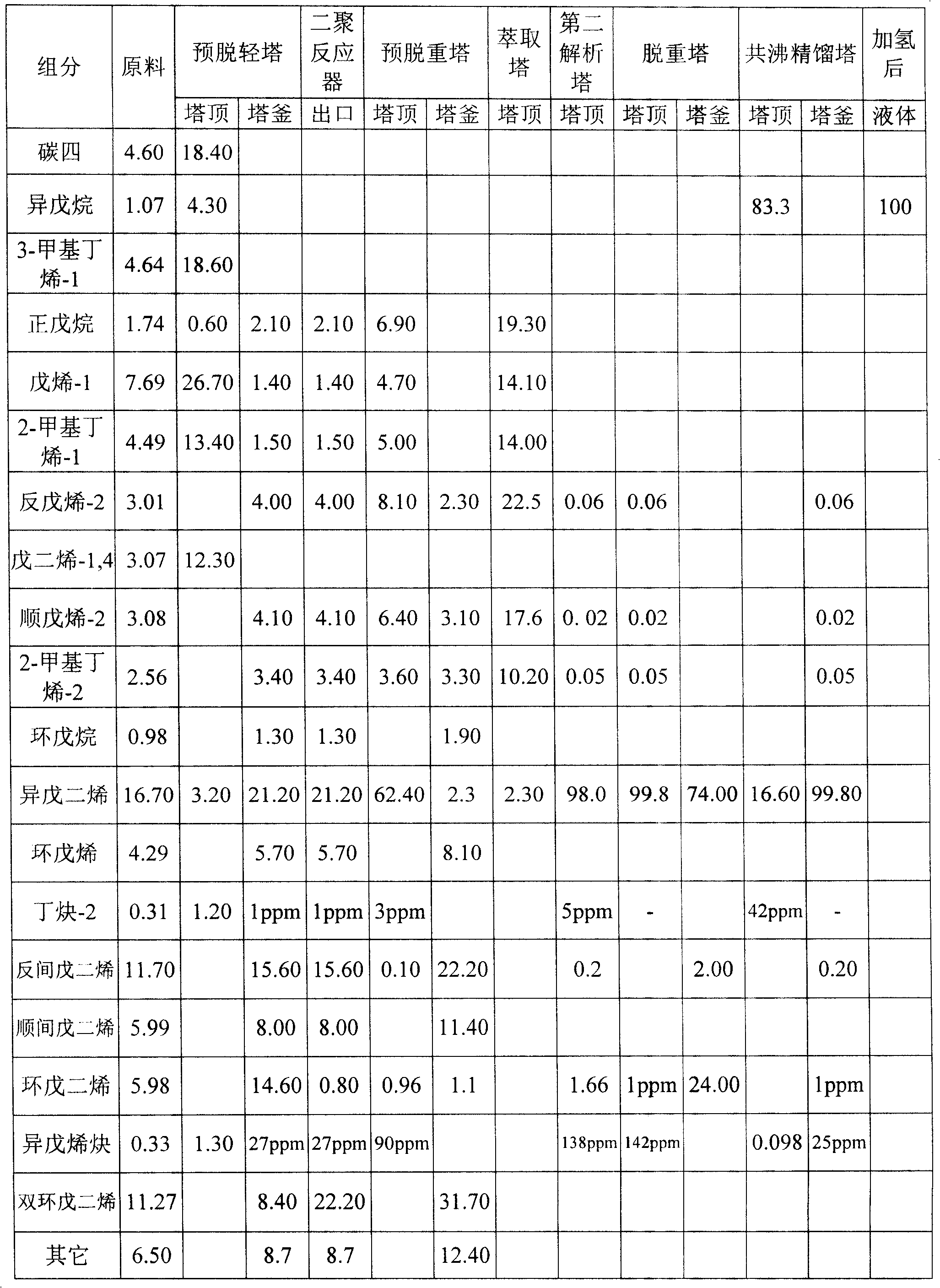

[0042] The cracked C5 fraction of Yanshan Petrochemical Company is used as the raw material, and the separation method of the present invention is used to separate the cracked C5 fraction. The composition of the raw material and the composition of the incoming and outgoing materials of each operating device are listed in the following table.

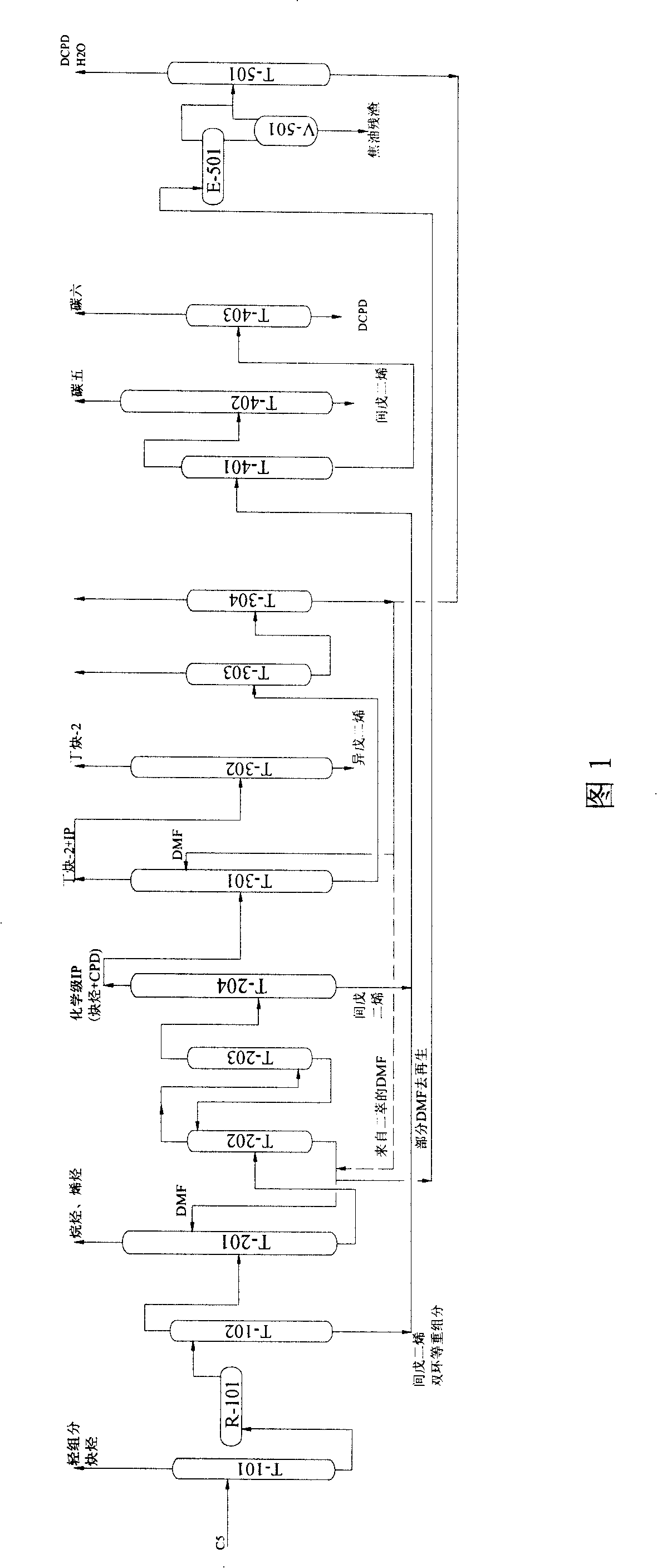

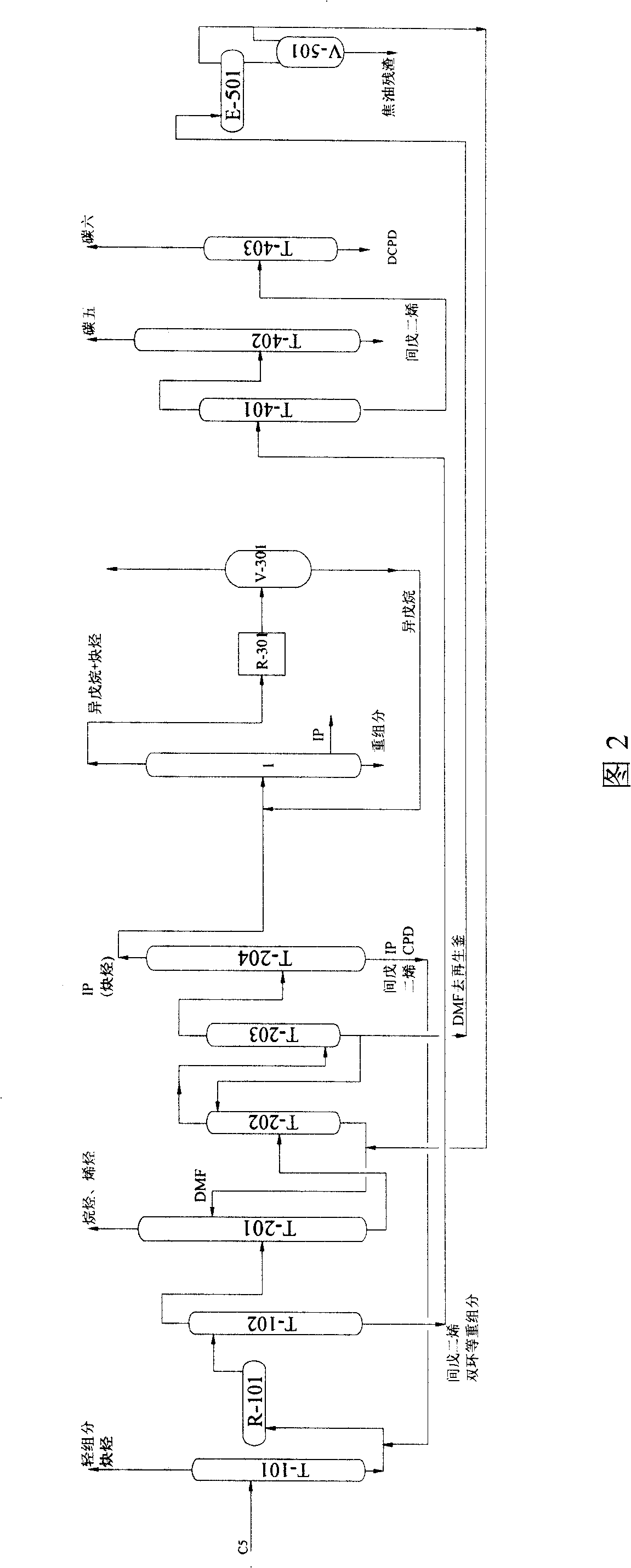

[0043] (1) Pretreatment unit: 31,000kg / h of cracked C5 fraction enters the middle part of the pre-light removal tower T-101. The pre-light removal tower T-101 has 80 theoretical plates, the reflux ratio is 22, and the tower top temperature is 45°C , remove the light components containing C4, alkynes and alkanes from the top of the tower, and the materials extracted from the tower reactor enter the dimerization reactor R-101, and carry out the dimerization reaction at 80-85°C to make the cyclopentyl Diene is dimerized into dicyclopentadiene, and then enters the pre-weight removal tower T-102. The pre-weight removal tower T-102 has 85 theor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com