Method for improving zero-valent iron dechromisation catalytic reduction liveness in neutrality condition

A zero-valent iron and ferrous sulfate technology, applied in chemical instruments and methods, reduced water/sewage treatment, photography technology, etc., can solve problems such as unsatisfactory and low catalytic reduction activity, and achieve convenient operation and good application prospects. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

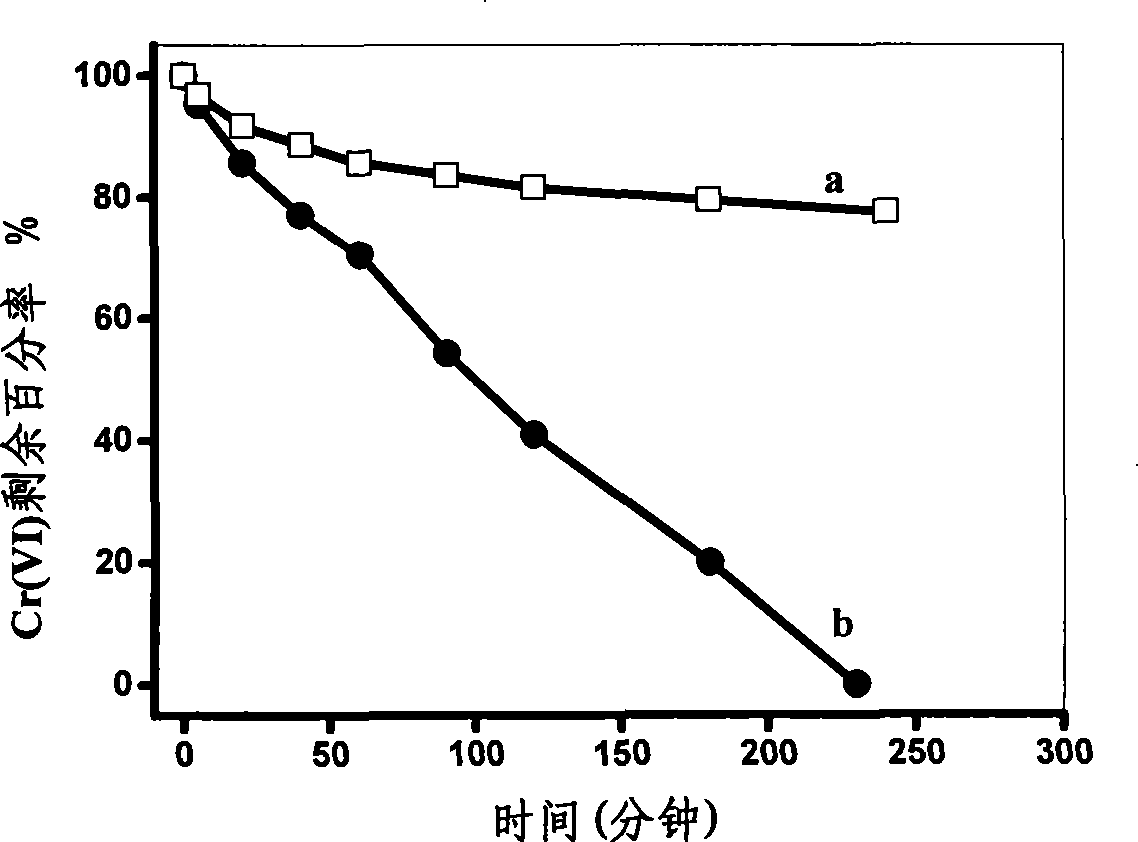

Embodiment 1

[0021] Prepare the electrolyte containing 0.1mol / L ferrous sulfate, 0.3mol / L boric acid, 0.4mol / L ammonium sulfate, 0.003mol / L ascorbic acid, 0.003mol / L saccharin, 0.002mol / L sodium lauryl sulfate, The pretreated titanium sheet was used as the working electrode, using 10mA / cm 2 current electrodeposition for 60 min. Add 20 mg of the zero-valent iron obtained into a solution with a Cr(VI) concentration of 10 mg / L, adjust the pH of the solution to 7.0, analyze the catalytic reduction activity of the zero-valent iron, and do not add ascorbic acid, saccharin and lauryl sulfate with other conditions the same The zero-valent iron obtained by electrodeposition in the electrolyte of sodium was used for comparison, and the results are shown in figure 1 .

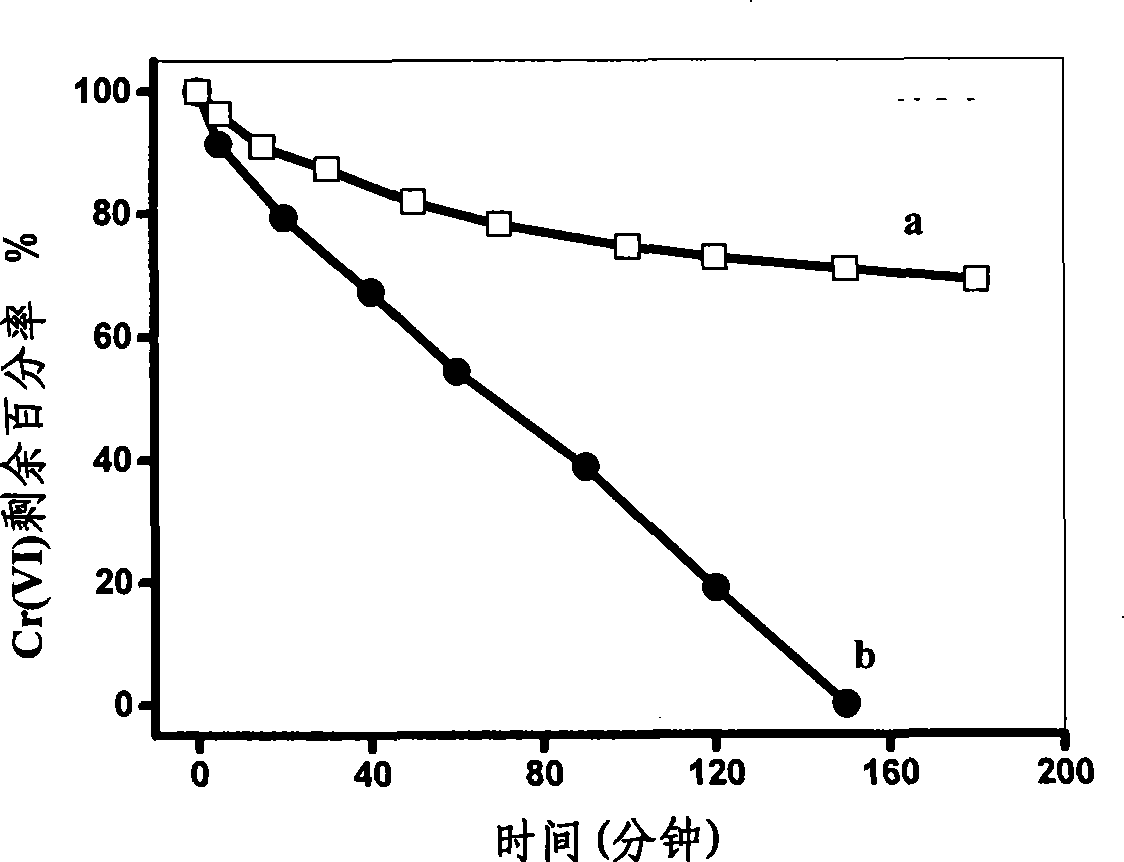

Embodiment 2

[0023] Prepare the electrolyte containing 0.1mol / L ferrous sulfate, 0.3mol / L boric acid, 0.4mol / L ammonium sulfate, 0.003mol / L ascorbic acid, 0.003mol / L saccharin, 0.002mol / L sodium lauryl sulfate, The pretreated titanium sheet was used as the working electrode, using 20mA / cm 2 current electrodeposition for 30 min. Add 20 mg of the obtained zero-valent iron into a solution with a Cr(VI) concentration of 5 mg / L, adjust the pH of the solution to 8.0, analyze the catalytic reduction activity of the zero-valent iron, and do not add ascorbic acid, saccharin and lauryl sulfate with other conditions the same The zero-valent iron obtained by electrodeposition in the electrolyte of sodium was used for comparison, and the results are shown in figure 2 .

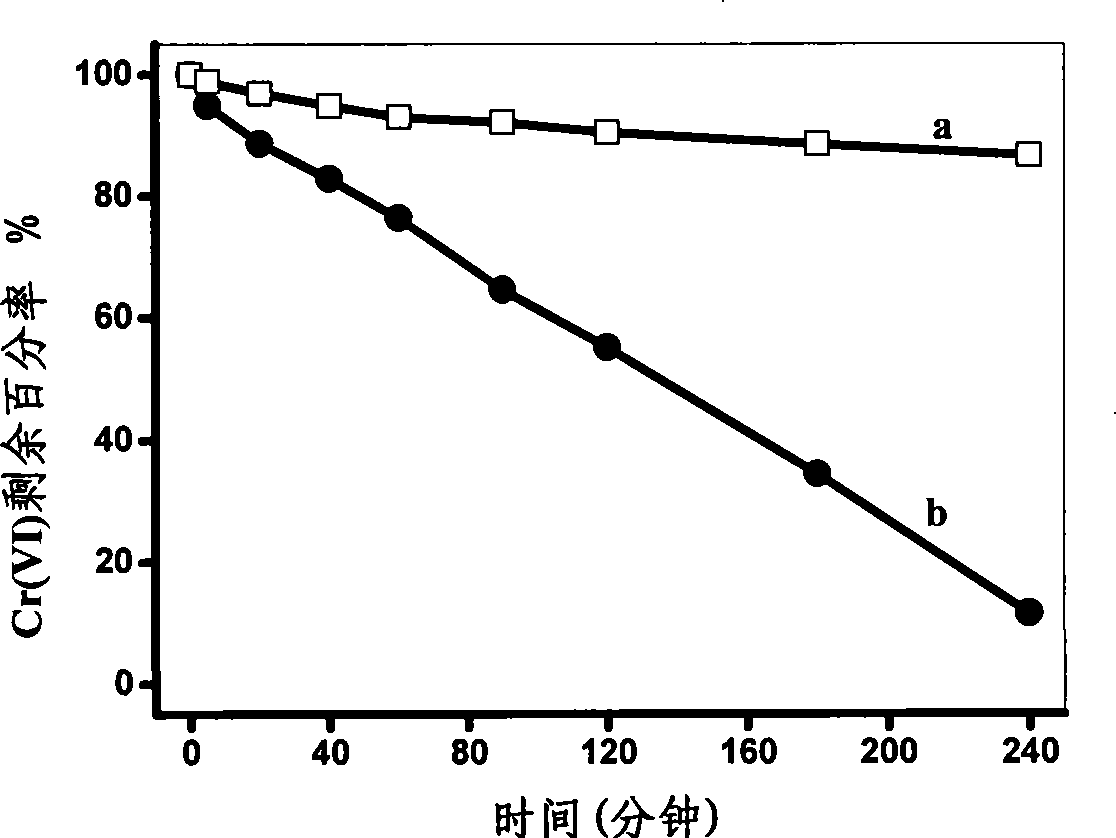

Embodiment 3

[0025] Prepare an electrolyte containing 0.2mol / L ferrous sulfate, 0.4mol / L boric acid, 0.5mol / L ammonium sulfate, 0.004mol / L ascorbic acid, 0.004mo / L saccharin, and 0.003mol / L sodium lauryl sulfate , with the pretreated titanium sheet as the working electrode, using 10mA / cm 2 current electrodeposition for 60 min. Add 30 mg of zero-valent iron obtained into a solution with a Cr(VI) concentration of 20 mg / L, adjust the pH of the solution to 6.5, analyze the catalytic reduction activity of zero-valent iron, and do not add ascorbic acid, saccharin and dodecylsulfuric acid with other conditions the same The zero-valent iron obtained by electrodeposition in the electrolyte of sodium was used for comparison, and the results are shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com