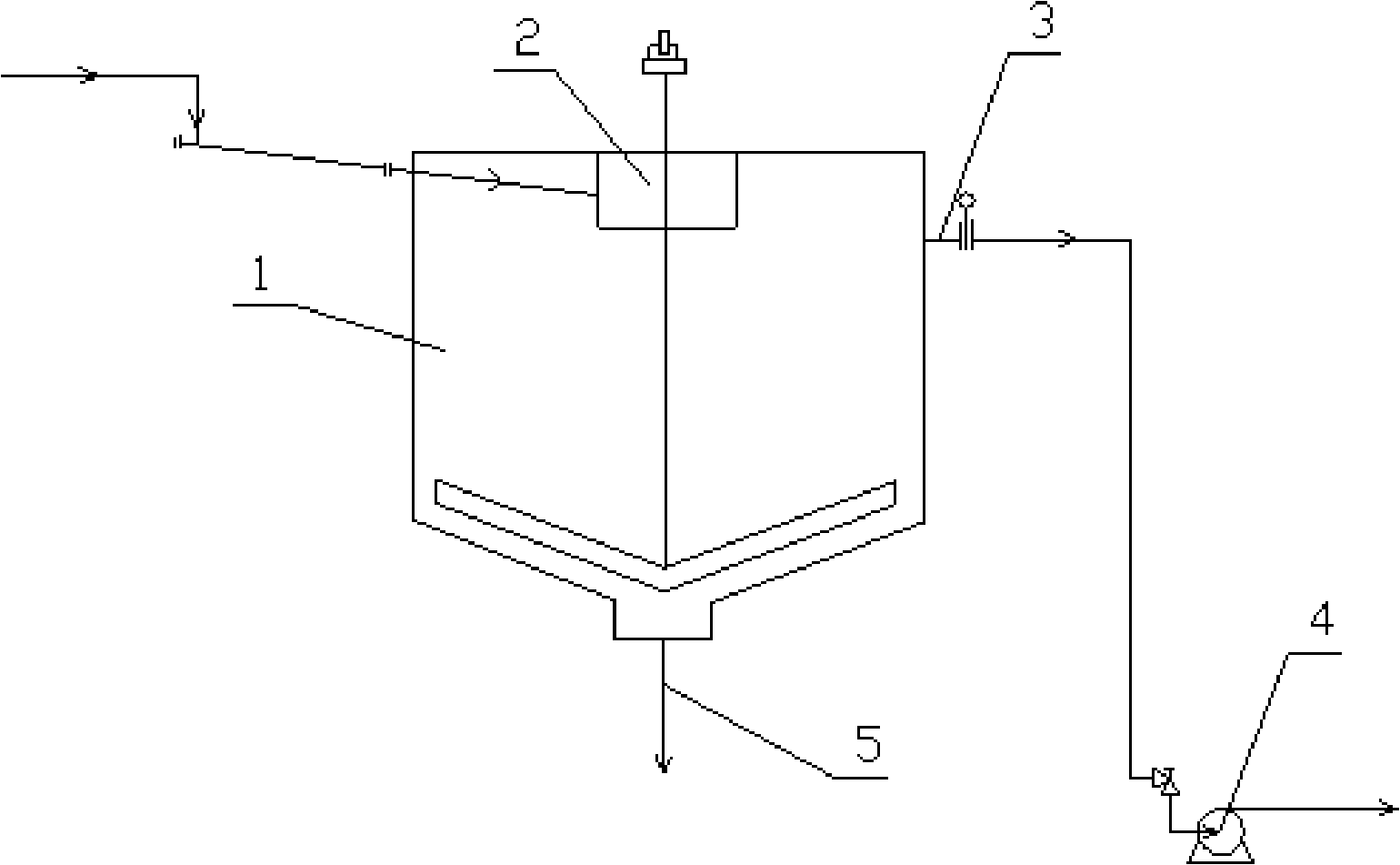

Method for reducing slip solid content of setting tank

A solid content, settling tank technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of high solid content of slurry entering the settling tank, poor liquid-solid separation effect, poor settling performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

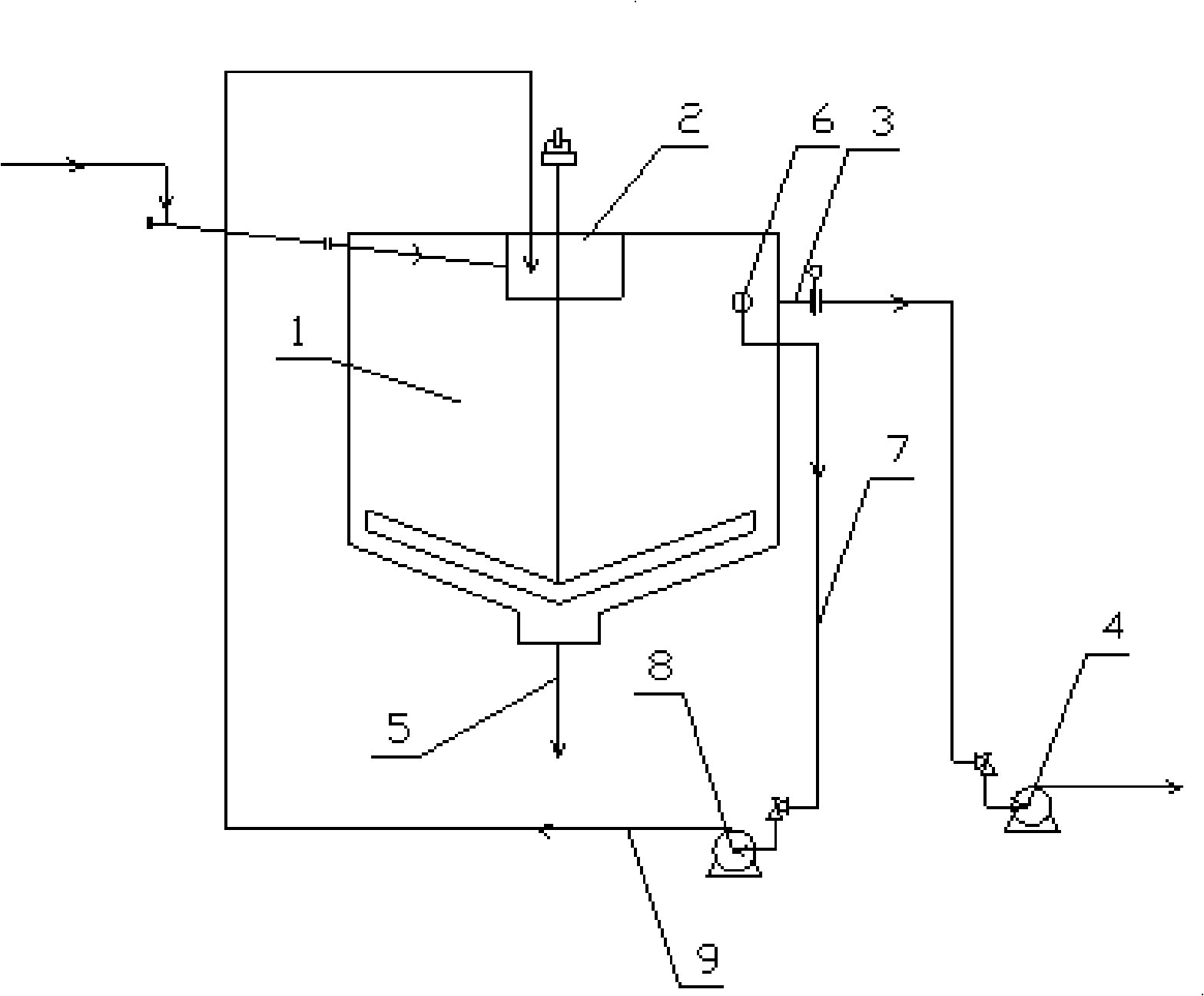

[0009] Embodiment of the present invention: on the settling tank 1 of the prior art, an overflow port, namely the second overflow port 6 is added, the circulation pipe 7 is connected on the second overflow port 6, and the circulation pipe 7 is connected with the circulation pump 8 , the outlet of the circulating pump 8 is connected to the pipeline 9, and the pipeline 9 is connected to the slurry feeding well 2.

[0010] Circulation pump 8 adopts frequency conversion speed regulation, in order to timely adjust the addition of crude liquid according to the change of the solid content of the feed slurry.

[0011] During work, the high-pressure dissolved ore pulp (red mud) from the previous section enters the settling tank 1 through the slurry feed well 2 for liquid-solid separation, and its overflow is sent to the In the next process, the underflow flows out from the underflow outlet 5 at the lower part of the settling tank 1; at the same time, part of the crude liquid enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com