Method and device for recycling anhydrous sodium sulfate from desulfurization lead plaster filter liquor

A technology of anhydrous sodium sulfate and desulfurization lead paste, which is applied in the field of resource recovery and utilization technology, and can solve the problems of different recovery methods of anhydrous sodium sulfate and different sources of waste liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

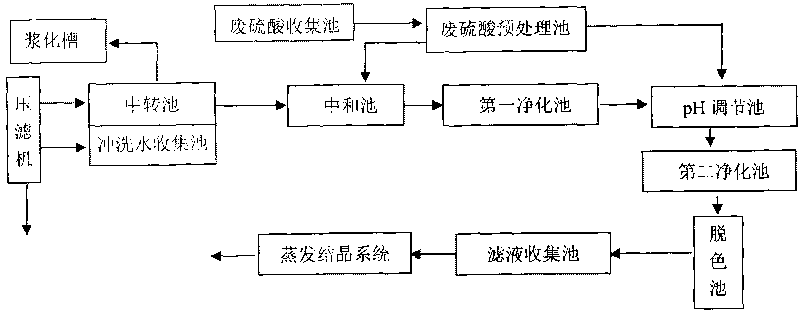

[0024] Such as figure 1 As shown, the device of the present invention includes a transfer tank, a flushing water collection tank, a waste sulfuric acid collection tank, a waste sulfuric acid pretreatment tank, a neutralization tank, a first-level purification tank, a pH adjustment tank, a second-level purification tank, a decolorization tank, Filtrate collection tank and evaporation crystallization system.

[0025] When the specific gravity of the filtrate collected in the intermediate tank is less than 1.200, the filtrate will be sent back to the slurry tank for recycling; when the specific gravity of the filtrate is ≥ 1.200, the filtrate will be sent to the neutralization tank; After the battery electrolyte is sulfuric acid, it is sent to the waste sulfuric acid pretreatment tank for pretreatment. The pretreatment is to remove oil and suspended matter by air flotation, and remove insoluble substances through a microporous filter; the pretreated waste sulfuric acid is put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com