Pre-combustion chamber utilizing low-concentration gas

A low-concentration gas, pre-combustion chamber technology, used in fuel systems, combustion engines, internal combustion piston engines, etc., can solve problems such as low utilization efficiency, environmental pollution, and difficulty in gas ignition, and achieve the effect of preventing the influence of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

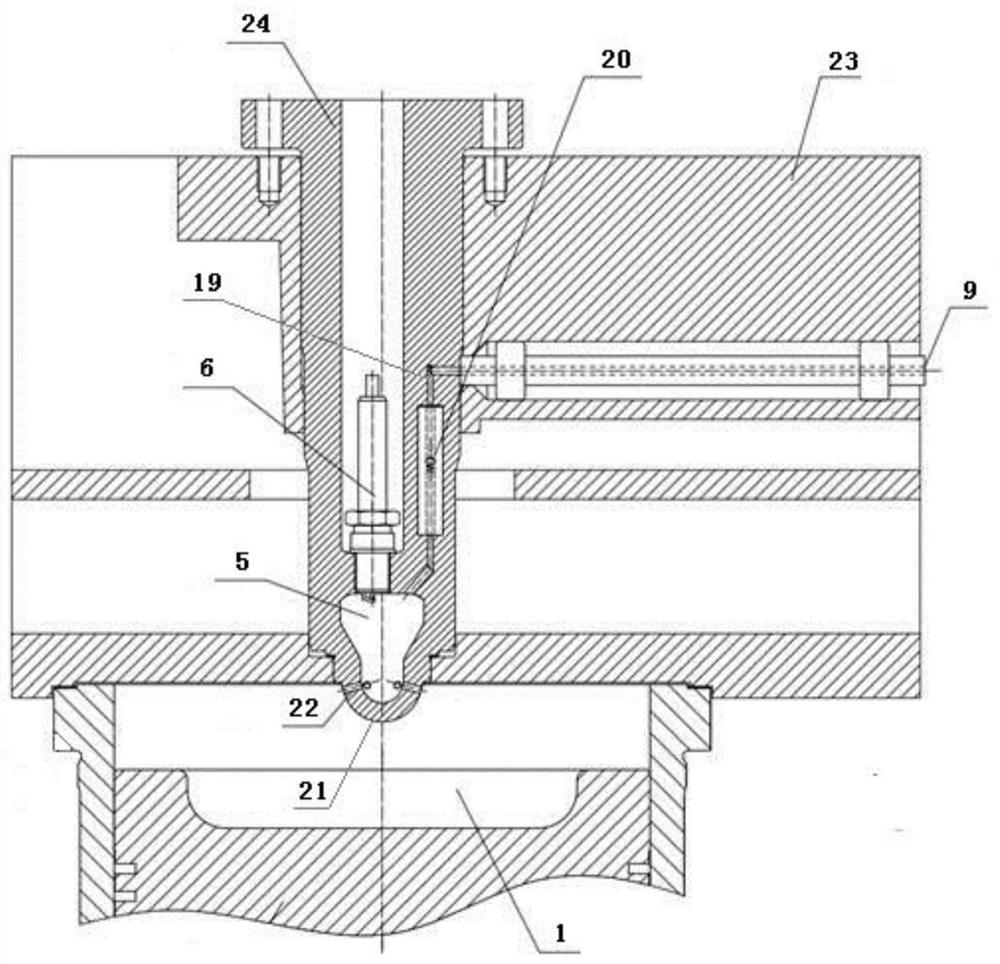

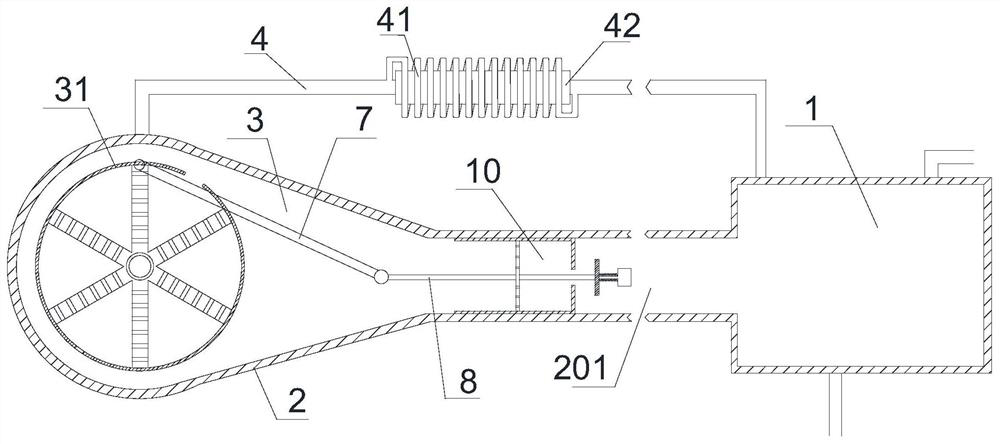

[0046] Example: such as Figure 1 to Figure 7 As shown, a pre-chamber utilizing low-concentration gas includes a pre-chamber combustion chamber 5 and a spark plug, and also includes an intake passage 19 and a one-way control valve 20;

[0047] The intake passage 19 communicates with the pre-chamber combustion chamber 5 through the one-way control valve 20 , and the spark plug is used to ignite the gas inside the pre-chamber combustion chamber 5 .

[0048] In this embodiment, in order to ignite the low-concentration gas in the main combustion chamber 1, an intake passage 19 is provided on the cylinder liner and the spark plug sheath 24, and a pre-combustion chamber intake port 9 is provided outside the intake passage 19. The high-concentration liquefied natural gas is gasified and adjusted to a certain pressure, and then enters the pre-combustion chamber inlet 9, and enters the air intake passage 19, and finally enters the pre-chamber combustion chamber 5 along the air intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com