Hydraulic water, oil squeezing apparatus

A hydraulic and capping technology, used in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problem of low strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

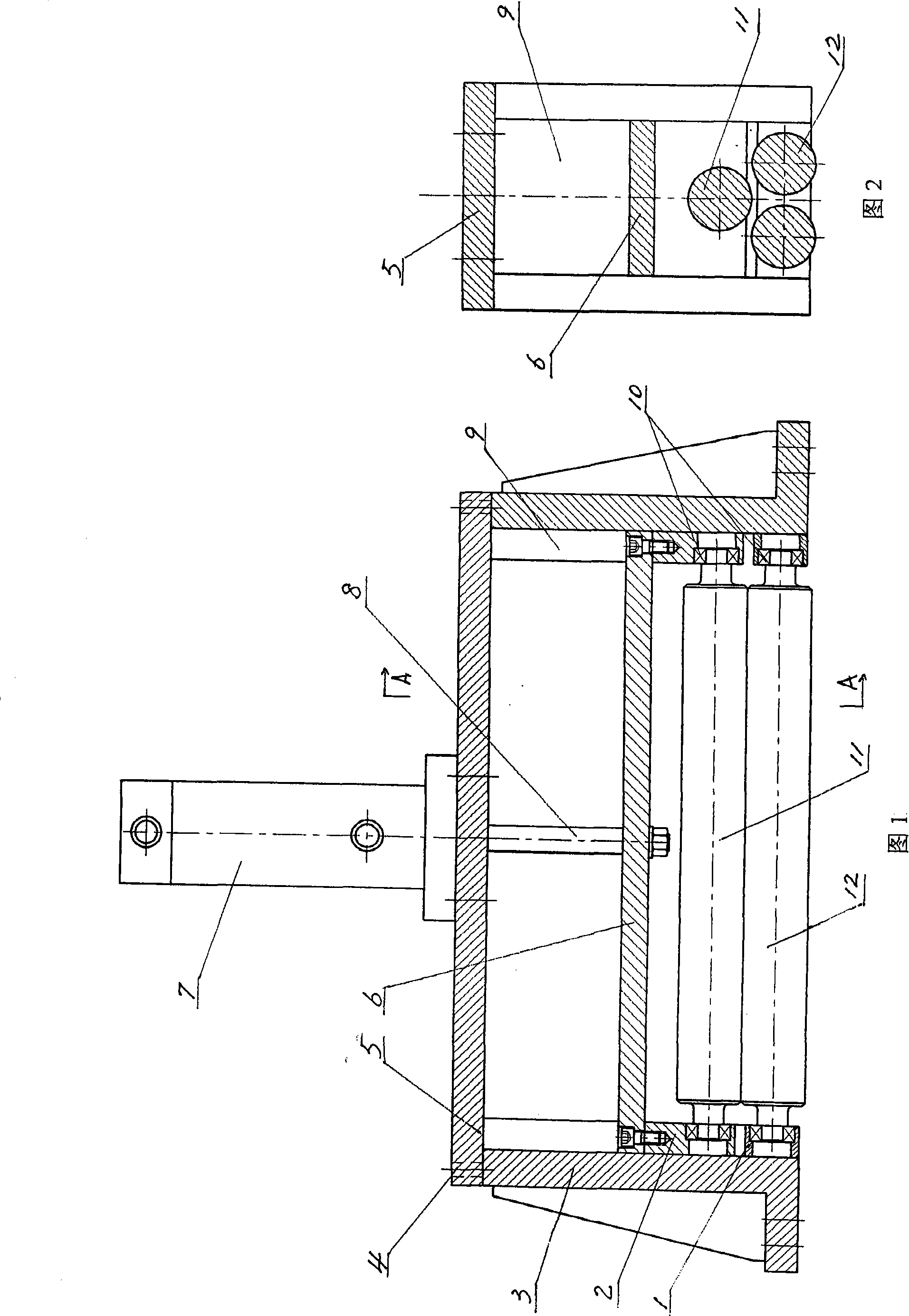

[0011] As shown in Figures 1 and 2, the hydraulic water and oil squeezing device of the present invention includes two plate-shaped supports 3, which are arranged in parallel and opposite to each other, and a gland 5 is arranged between their top ends. Both ends of the gland 5 are respectively fixed on the top ends of the two plate-shaped supports 3 by means of screws 4 . Vertical chute 9 is processed in the middle of the inner surfaces of the two plate-shaped supports 3, and upper bearing seat 2 and lower bearing seat 1 are installed in the two vertical chute, and upper bearing seat 2 can be moved along the vertical chute 9. Swipe up and down. An upper roller 11 is arranged between the two upper bearing seats 2, and the two ends of the upper roller 11 extend into the two upper bearing seats 2 by means of bearings 10 respectively. A lower roller 12 is arranged between the two lower bearing seats 1, and the two ends of the lower roller 12 extend into the two lower bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com