Recovery of energy in a hybrid vehicle comprising a hydraulic or pneumatic braking system

一种混合动力汽车、制动压力的技术,应用在混合动力车辆、通用动力装置的多个不同原动机的布置、制动传动装置等方向,能够解决最大电功率不能充分利用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

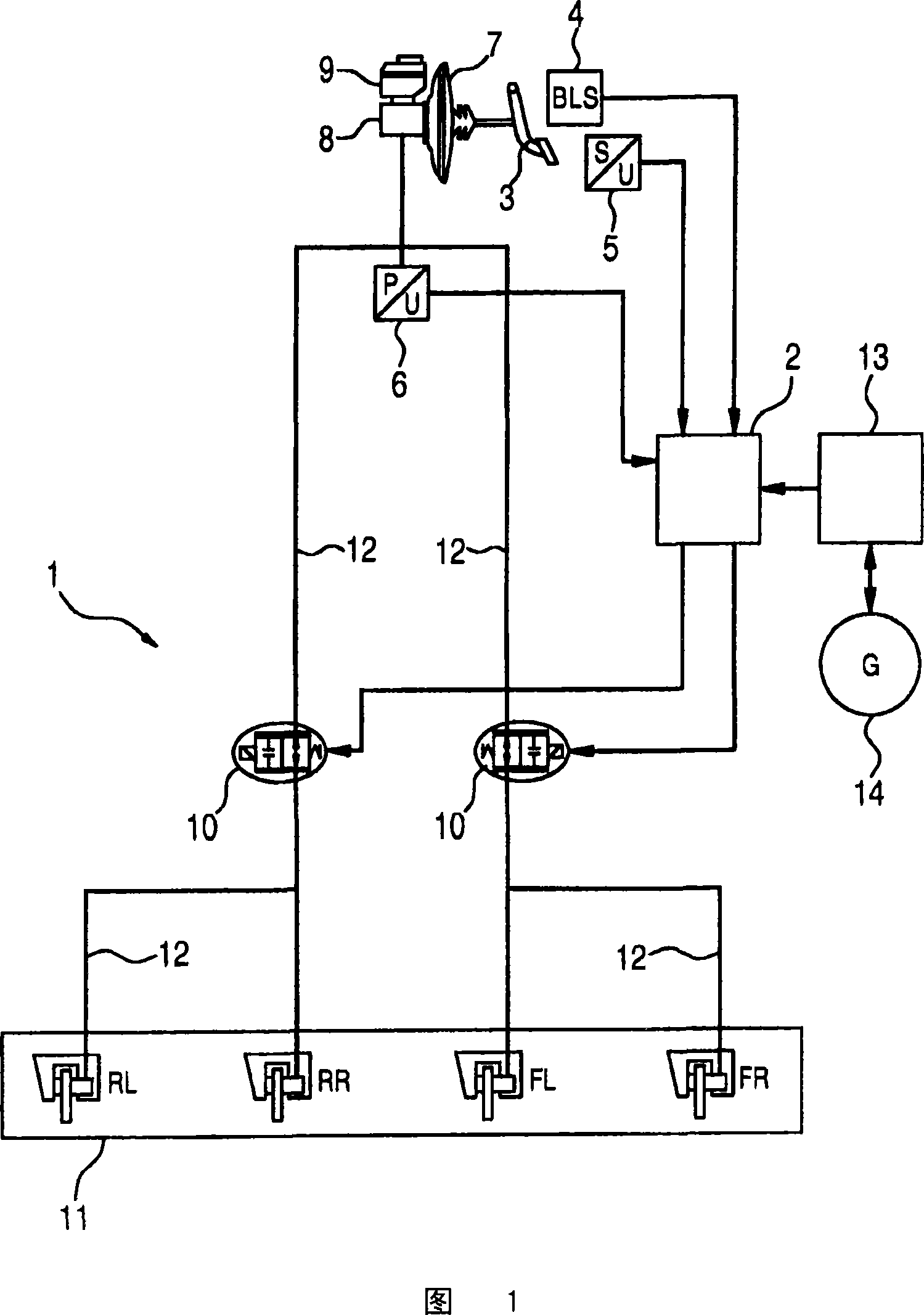

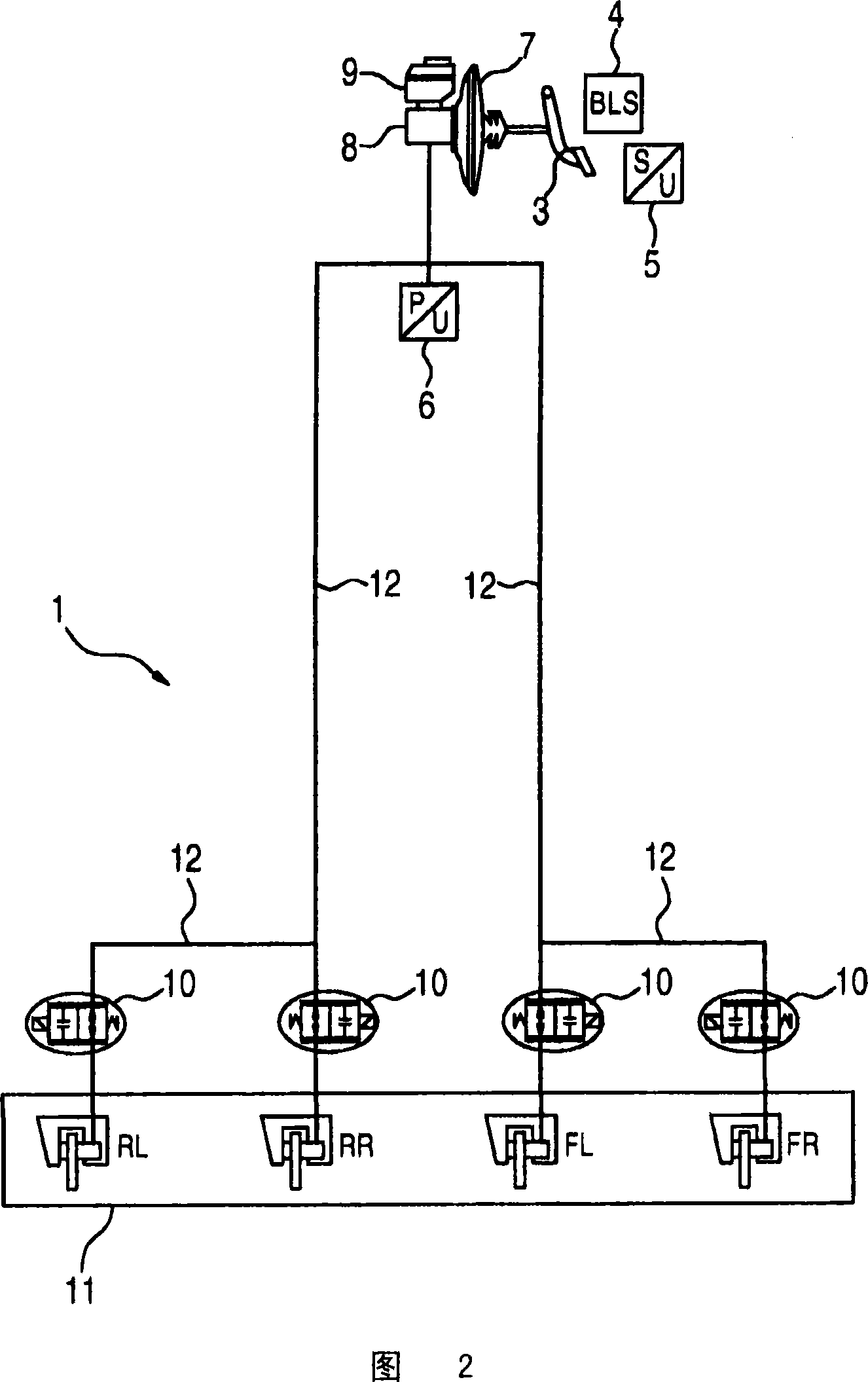

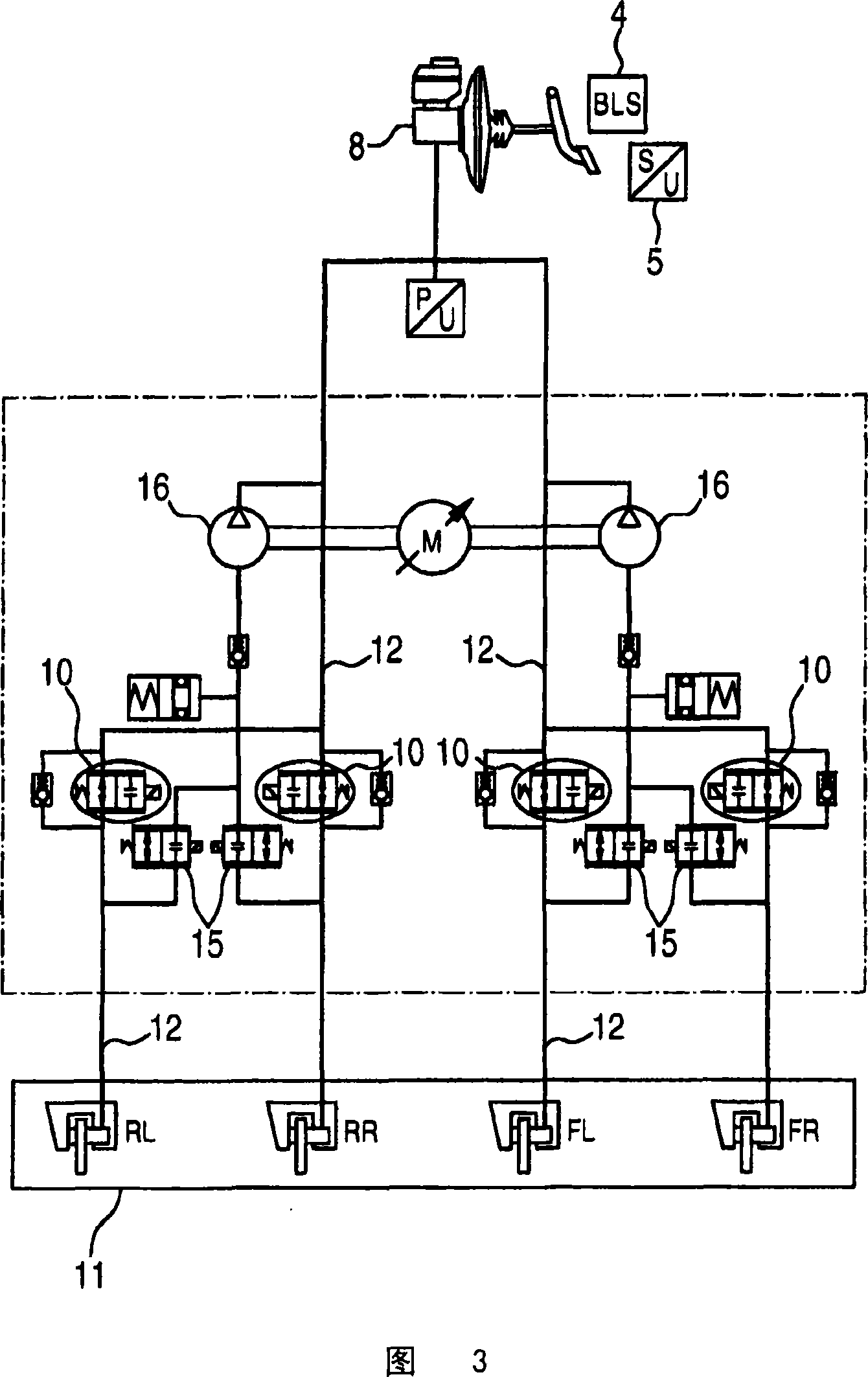

[0021] FIG. 1 shows a hydraulic vehicle brake system with a type II circuit distribution, the configuration of which is basically known from the prior art. As is known, the braking device 1 comprises a foot brake pedal 3, a brake booster 7 with a master brake cylinder 8 on which a brake fluid container 9 is arranged. . The brake booster 7 increases the braking force exerted by the driver on the foot brake pedal 3 and generates a brake pressure which is directed via the brake line 12 to the wheel brakes 11 .

[0022] Unlike known braking devices, this brake device includes an additional valve 10, which is arranged in the main-brake line 12 of the driven axle and whose function is to reduce the force applied by the driver. brake pressure. Two valves 10 are shown here, of which only the left valve is installed in the case of rear-wheel drive, only the right valve is installed in the case of front-wheel drive, and both valves 10 are installed in the case of all-wheel drive. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com