Producing and processing technique for terylene low-elasticity wire

A processing technology, technology of fine denier polyester, applied in the direction of fabric elongation, feeding solution to spinneret, single-component polyester rayon filament, etc., can solve the impact of the high price of sea-island yarn on the scope of use and popularity and other problems, to achieve the effect of stable product quality and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] Embodiment, this example is the technological process of ultra-fine denier polyester filament:

[0011] Polymerization melt→melt conveying→spinning box→metering pump→component→inner ring blowing cooling→cluster oiling→column→pre-network→first godet→main network→second godet→winding→ Inspection→Balance→Transfer false twist

[0012] POY→raw frame→cutter→first roller→twist stopper→first hot box→cooling plate→false twister→second roller→networker→auxiliary roller→second hot box→third roller→explorer Filament→oiling roller→winding→inspection→packing

[0013] The processing method is completed by two processes of spinning and texturing. The spinning adopts the inner ring air blowing cooling technology, and the texturing adopts the combination technology of 1-3-1 polyurethane friction sheet.

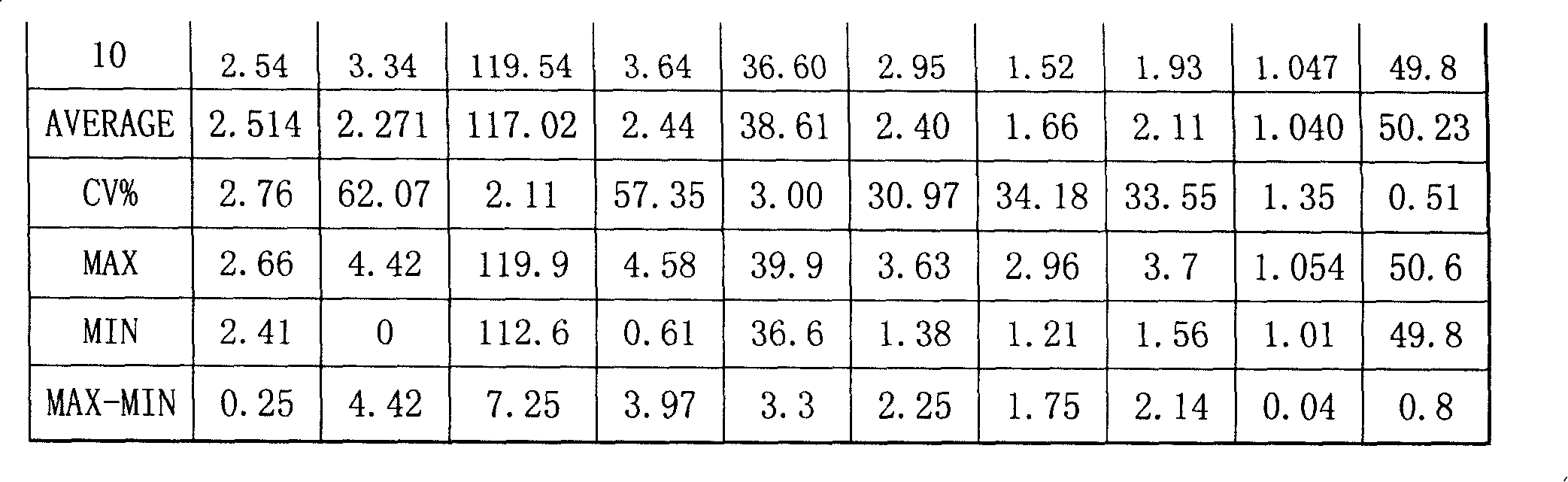

[0014] The following table shows the physical properties of POY:

[0015]

[0016]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap