Eight-frequency ultrasonic wave apocynum degumming device

An ultrasonic and frequency technology, applied in the direction of ultrasonic/sonic fiber processing, textile and paper making, mechanical processing, etc., can solve the problem of cleaning the small colloids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

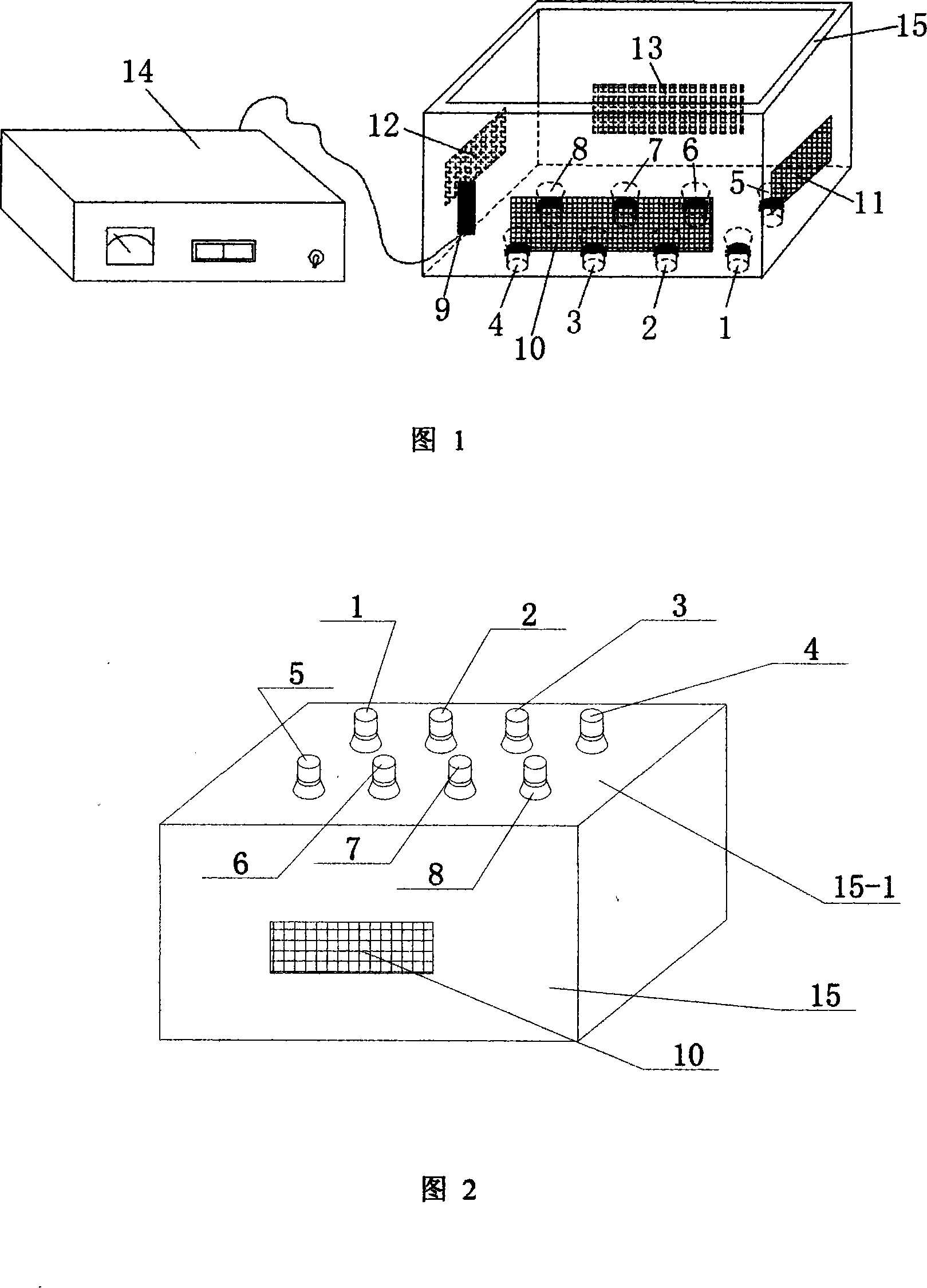

[0006] Referring to Fig. 1~2, present embodiment is made up of eight transducers 1~8, thermistor 9, four PTC heating plates 10~13, ultrasonic generator 14, bath 15, four PTC heating plates 10, 11, 12, and 13 are respectively installed on the four outer surfaces of the bath 15 and connected in parallel to the heater load end of the ultrasonic generator 14. The thermistor 9 is also installed on the outer surface of the bath 15, and its signal output terminal is connected to the ultrasonic wave The temperature test input terminals of the generator 14 are connected, and eight transducers 1, 2, 3, 4, 5, 6, 7, and 8 are respectively arranged on the bottom surface 15-1 of the bath 15.

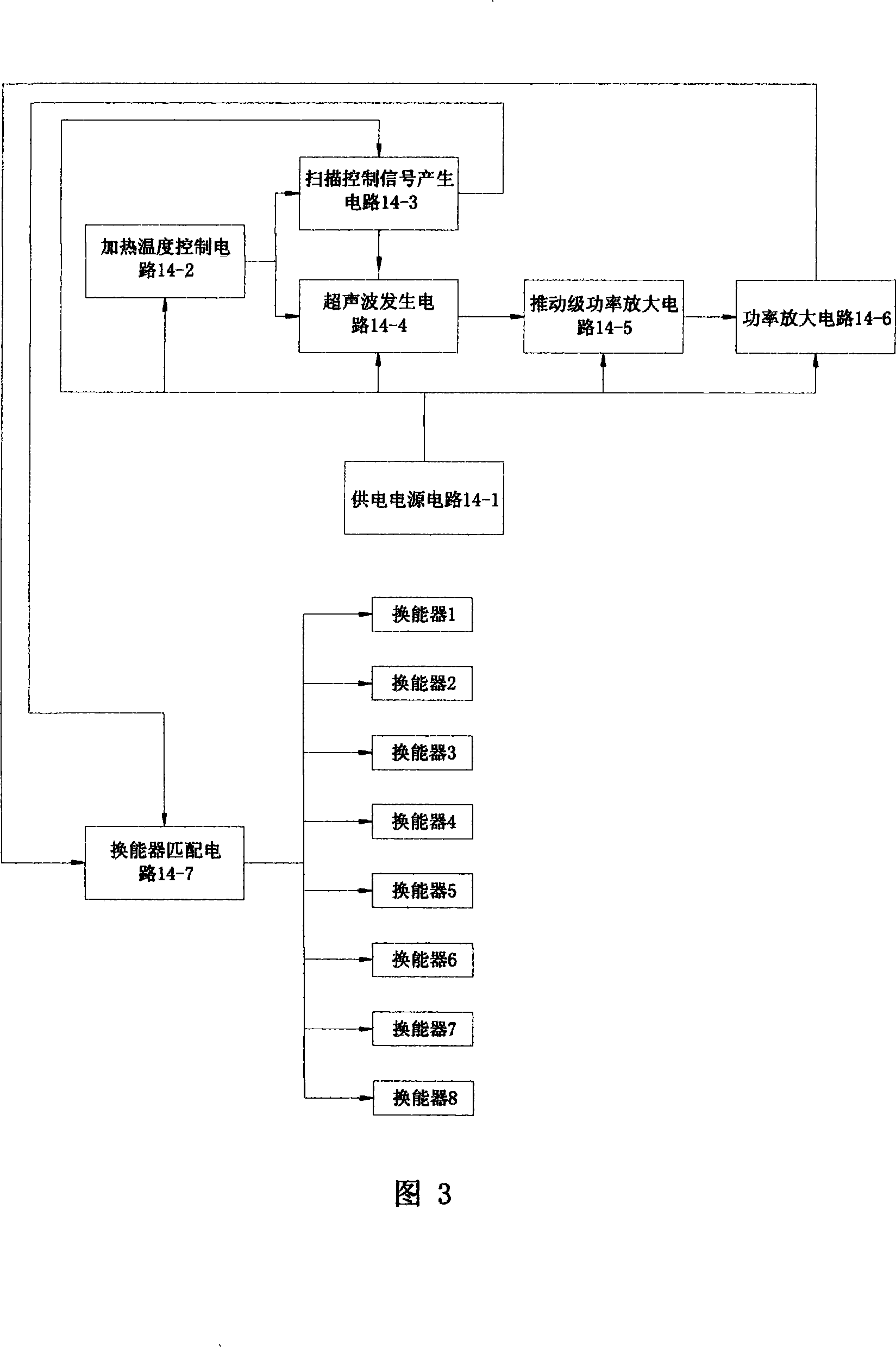

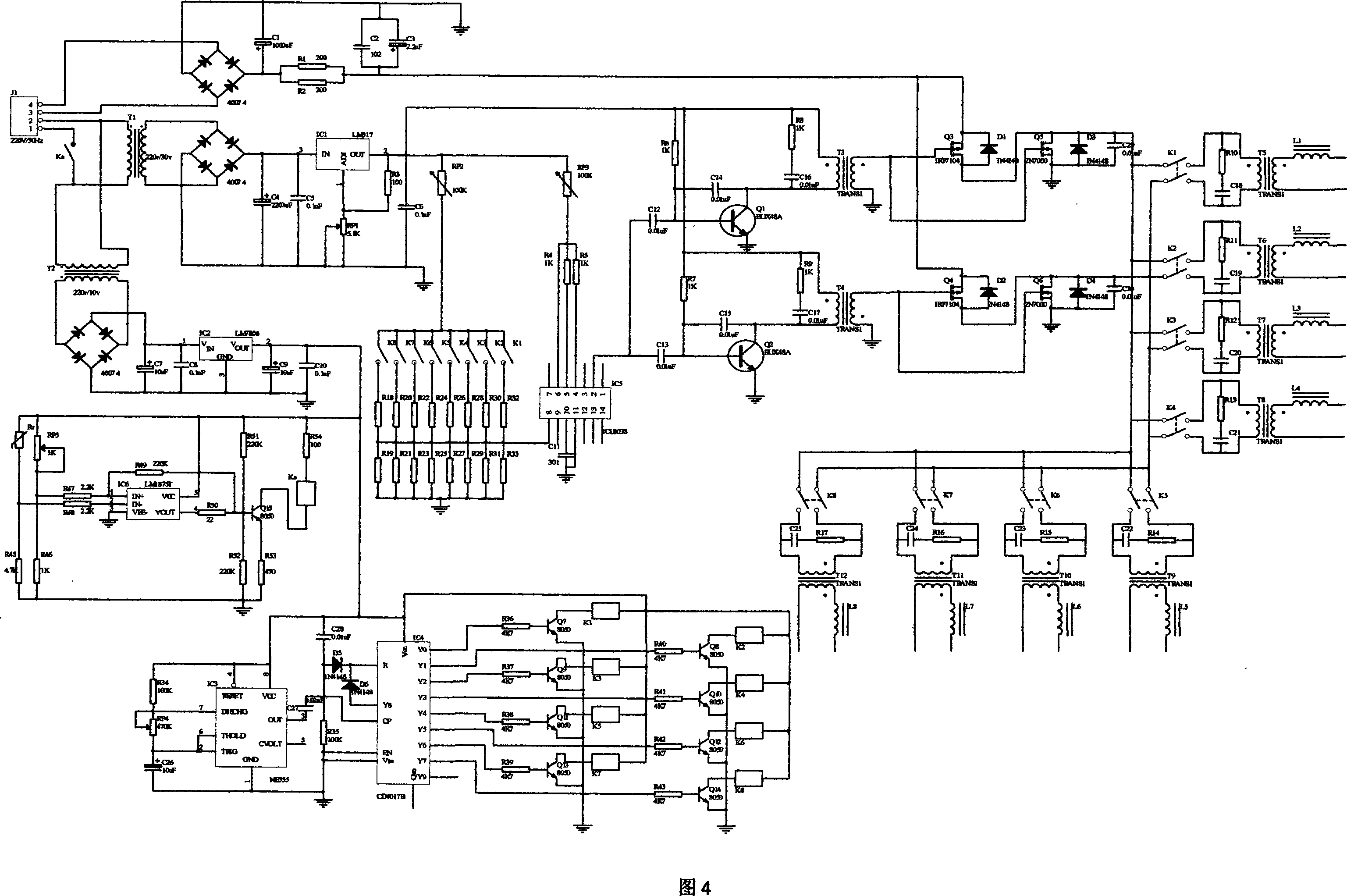

[0007] Referring to Fig. 3, the circuit of described ultrasonic generator 14 is by power supply circuit 14-1, heating temperature control circuit 14-2, scan control signal generation circuit 14-3, ultrasonic signal generation circuit 14~4, push stage power amplification Circuit 14-5, power amplifying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com