Method for correcting laser carving machine mechanism relative position

A laser engraving machine, relative position technology, applied in engraving, laser welding equipment, decorative art, etc., can solve the problems of mechanism work difference, vibration, shaking, cumbersome procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

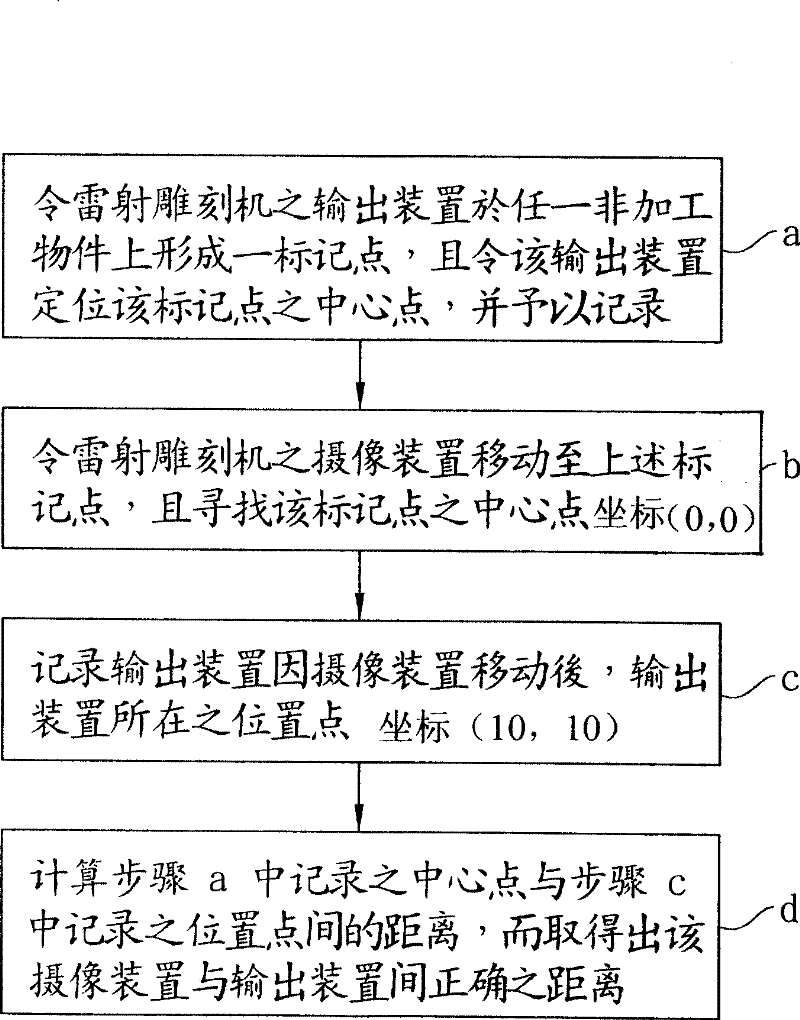

[0013] see figure 1 , the content of the accompanying drawing is a flow chart of an embodiment of the method for correcting the relative position of the mechanism in the laser engraving machine according to the present invention, which includes the following steps:

[0014] a. Let the output device of the laser engraving machine form a marking point on any non-processing object, and make the output device locate the center point of the marking point and record it;

[0015] b. Make the camera sensor device (CCD) of the laser engraving machine move to the above-mentioned marking point, and find the center point of the marking point;

[0016] c. Record the position of the output device after the camera sensor device moves; and

[0017] d. Calculate the distance between the center point recorded in step a and the position point recorded in step c, so as to obtain the correct distance between the camera sensing device and the output device.

[0018] Among them, the recording and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com