Sulfuric acid refining preprocessing method of life refuse burning flying ash

A technology for incineration and pretreatment of domestic waste, applied in the field of environmental engineering, can solve problems such as hindering cement hydration and clogging of cement kilns, achieve the effects of harmless landfill resource utilization, and reduce leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

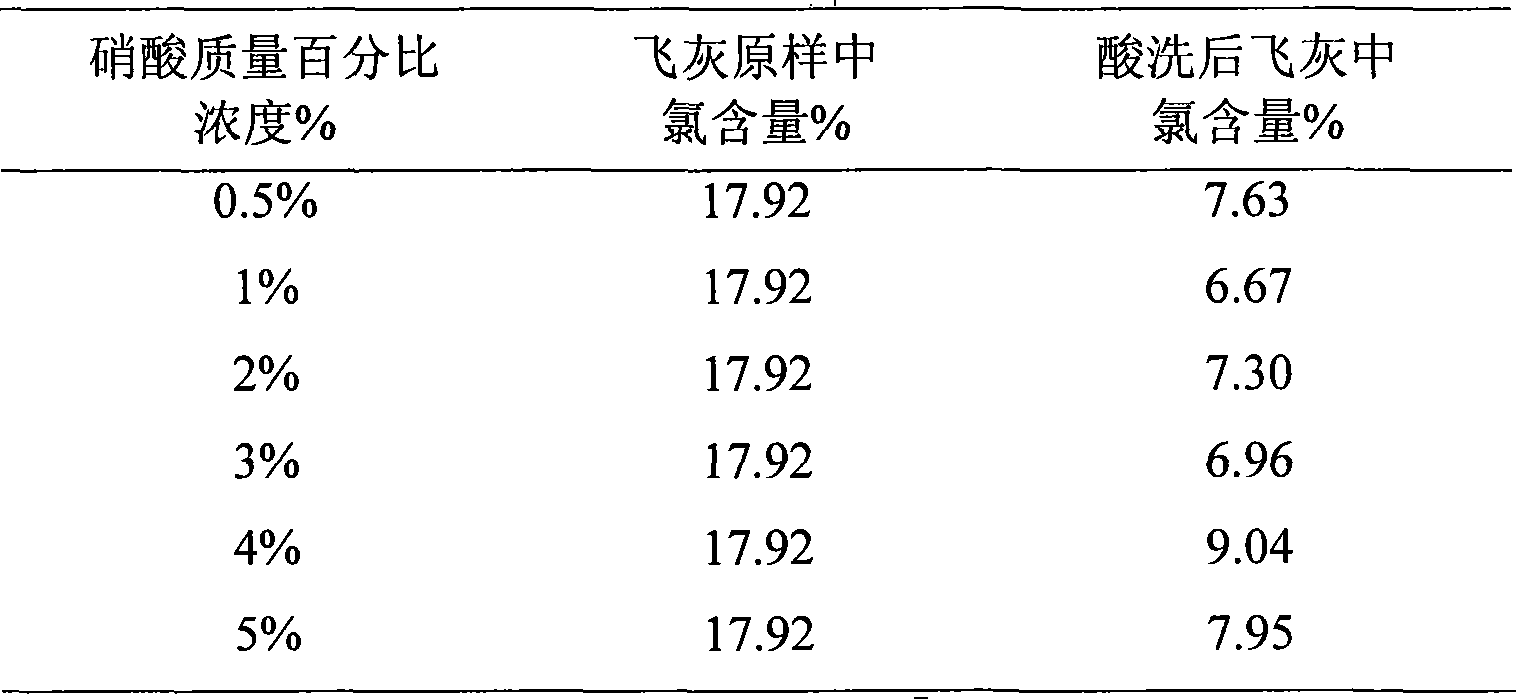

[0013] Under normal temperature and pressure conditions, add 100g of domestic waste incineration fly ash dried at 105°C for 24 hours into a beaker, add 1000mL of nitric acid solution with a concentration of 0.5% by mass, and start the stirrer to fully mix the two. Stir for 20-60 minutes, stand still for 10-20 minutes, separate the upper layer of acid solution and fly ash, analyze the concentration of heavy metals in the acid solution, and analyze the residual chlorine content in the fly ash. Then pickle the pretreated fly ash with nitric acid with a concentration of 1%, 2%, 3%, 4%, and 5% by mass percentage respectively, and repeat the above operation steps. The experimental results are shown in Tables 1 and 2.

[0014] Table 1 Effect of nitric acid pickling fly ash

[0015]

[0016] Table 2 Concentration of heavy metals in nitric acid solution after pretreatment of fly ash (mg / L)

[0017]

Embodiment 2

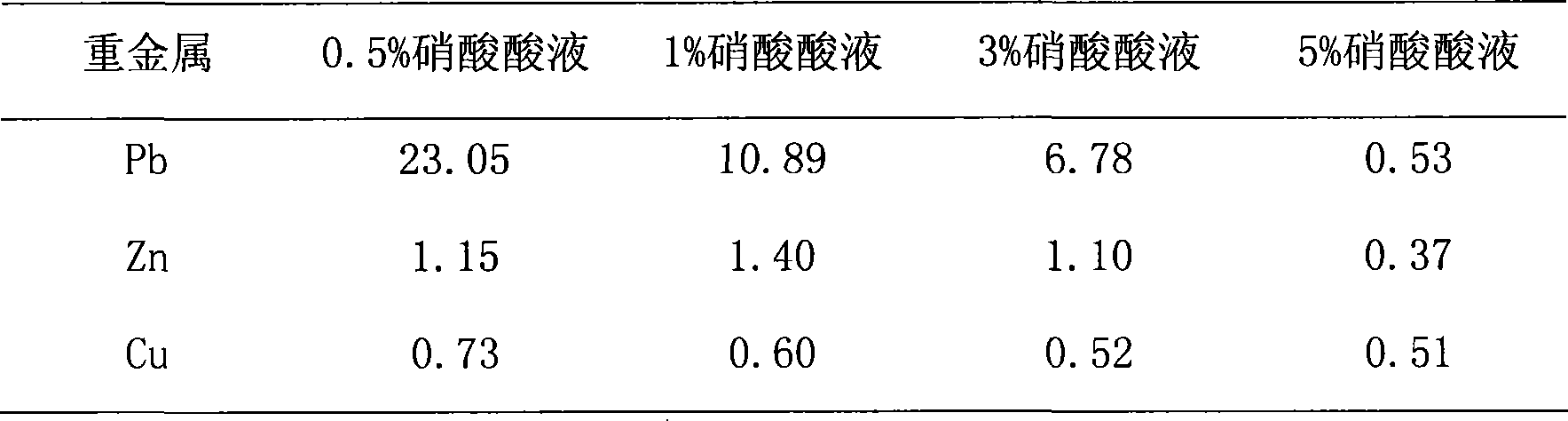

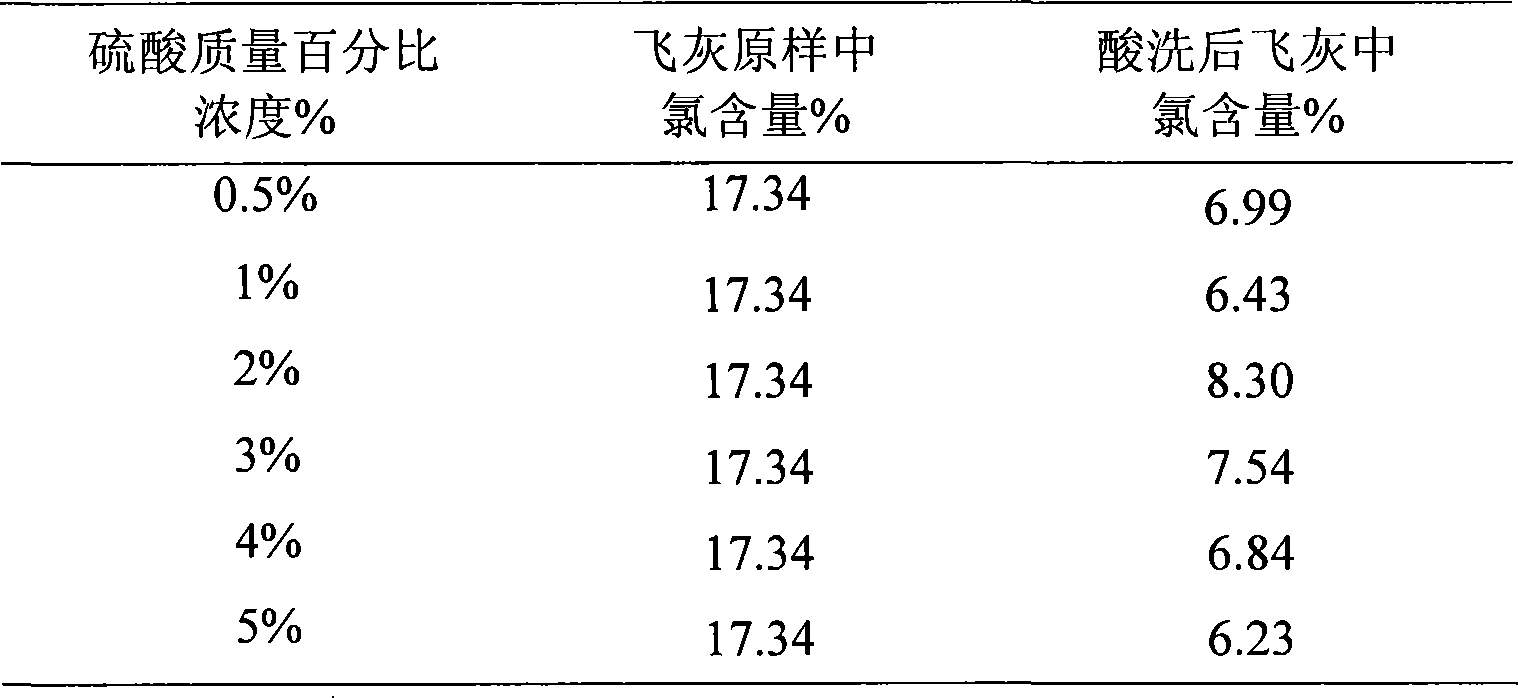

[0019] Under normal temperature and pressure conditions, add 100g of domestic waste incineration fly ash dried at 105°C for 24 hours into a beaker, add 1000mL of sulfuric acid solution with a concentration of 0.5% by mass, and start the stirrer to fully mix the two. Stir for 20-60 minutes, stand still for 10-20 minutes, separate the upper layer of acid solution and fly ash, analyze the concentration of heavy metals in the acid solution, and analyze the residual chlorine content in the fly ash. Then pickle the pretreated fly ash with sulfuric acid with a mass percent concentration of 1%, 2%, 3%, 4%, and 5%, respectively, and repeat the above operation steps. The experimental results are shown in Tables 3 and 4.

[0020] Table 3 Effect of sulfuric acid pickling fly ash

[0021]

[0022] Table 4 Concentration of heavy metals in sulfuric acid solution after pretreatment of fly ash (mg / L)

[0023]

Embodiment 3

[0025] Under normal temperature and pressure conditions, add 100g of domestic waste incineration fly ash dried at 105°C for 24 hours into a beaker, add 1000mL of acetic acid solution with a concentration of 0.5% by mass, and start the stirrer to fully mix the two. Stir for 20-60 minutes, stand still for 10-20 minutes, separate the upper layer of acid solution and fly ash, analyze the concentration of heavy metals in the acid solution, and analyze the residual chlorine content in the fly ash. Then pickling the pretreated fly ash with 1%, 2%, 3%, 4% and 5% acetic acid in concentration by mass percentage respectively, and repeating the above operation steps. The experimental results are shown in Tables 5 and 6. See Tables 7, 8, 9 and 10 for the test results of citric acid and phosphoric acid pickling fly ash.

[0026] Table 5 Effect of acetic acid pickling fly ash

[0027]

[0028] Table 6 Concentration of heavy metals in acetic acid solution after pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com