Solid phase extraction column with multi-wall carbon nano-tube matrix and preparation thereof

A multi-walled carbon nanotube and solid-phase extraction column technology, which is applied in the preparation of test samples, chemical instruments and methods, and other chemical processes, etc., can solve the problem of poor fluid passing ability, inability to pass solvent, and improper selection of carbon nanotubes. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Column material and specification

[0034]The specifications of the existing solid-phase extraction cartridges range from 50mg / 1mL to 10g / 60mL. The column tube material is polypropylene, and there are polyethylene sieve plates with 20 μm pore size on the upper and lower sides of the small column. All the above-mentioned column tubes can be used in the present invention. In the following examples, the present invention uses 0.25g-0.30g / 6mL.

[0035] 2. Granularity (length) of MWNTs

[0036] The packing particle size of the solid-phase extraction column is generally 20-60 μm, and the pore size of the polyethylene sieve plate is 20 μm. In order to prevent the filler from flowing out of the sieve plate, we choose MWNTs with a length of 5 μm-50 μm as the SPE filler.

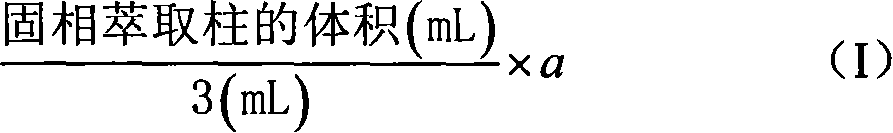

[0037] 3. Selection of filling volume and filling height

[0038] The flow rate of the SPE column is related to the analysis speed. Generally, the flow rate is required to be 0.5-1mL / min. If the rate is t...

experiment example 1

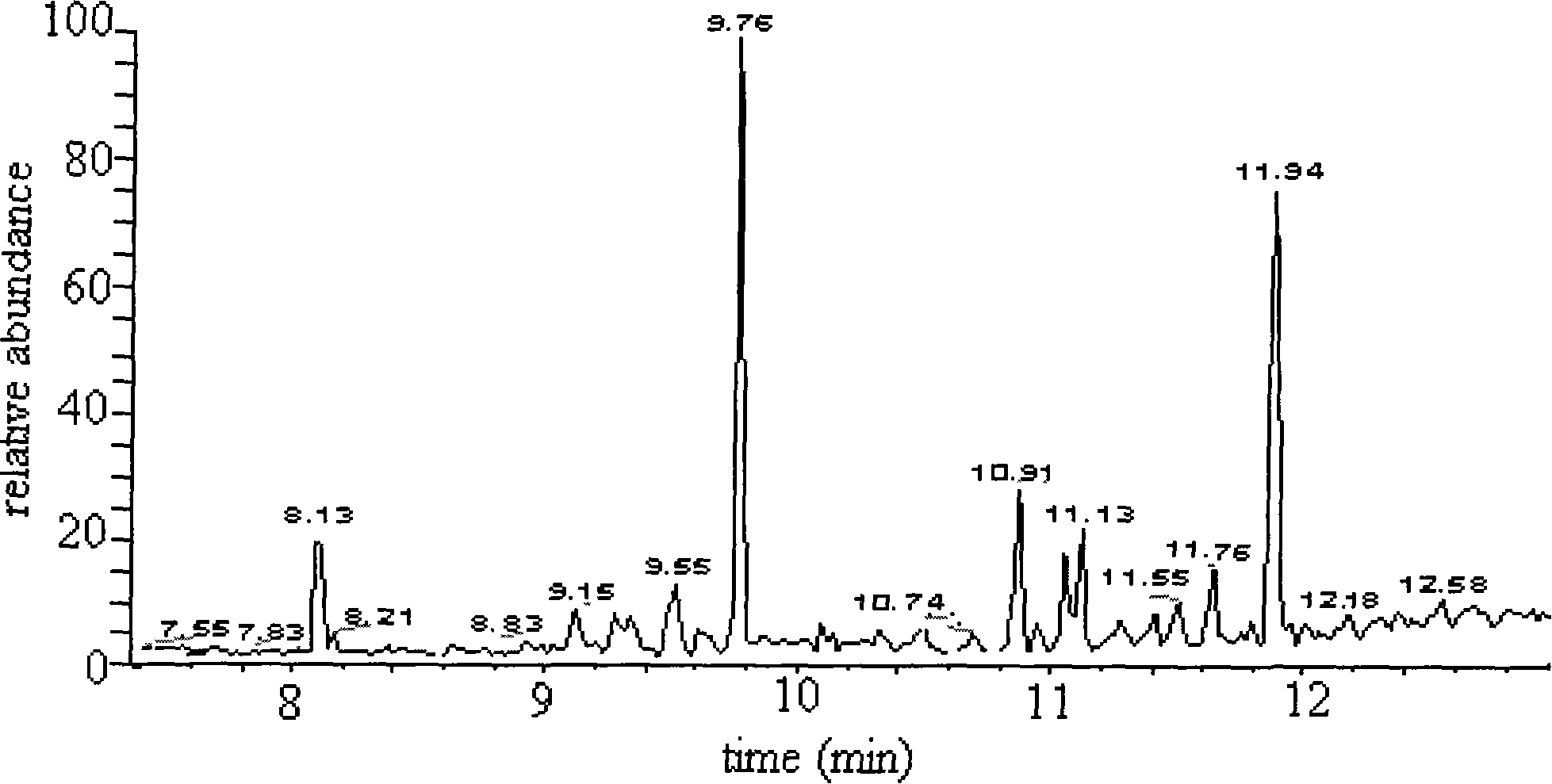

[0044] The pork sample was purified with a 6 mL SPE column packed in Example 1 and a commercially available C18 column.

[0045] MWCNTs SPE columns need to be pretreated with ethyl acetate, acetone or methanol before use.

[0046] The specific process is as follows: the sample was extracted with acetonitrile, dried by rotary evaporation, 5mL K2HPO4 (pH 7.4) buffer solution and 2mL NaAc (pH 7.0) buffer solution were added to the residue, vortexed to dissolve, and then loaded on the solid phase extraction column. The C18 SPE column was sequentially activated with 5 mL of n-hexane-ethyl acetate (7:3, v / v), 5 mL of methanol and 5 mL of NaAc (pH 7.0) buffer solution, and the flow rate was controlled at 1-1.5 mL / min to buffer the above samples. The solution was directly passed through the C18 SPE column or MWCNTs SPE column, and the column was equilibrated with 5mL NaAc buffer solution, and the water was removed under reduced pressure for 5min, followed by rinsing with 5mL n-hexane ...

Embodiment 2

[0049] The same method as in Example 1 was used to fill a 3mL solid-phase extraction column, the filling height was 0.8-1.1cm, and the filling volume was 0.12g-0.15g / 3mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com