Instant edible mushroom and preparation thereof

A technology of edible fungi and chicken fungus, which is applied in the field of preparation of instant edible fungi, can solve the problems of edible fungus flavor damage and cumbersome process, and achieve the effects of reducing greasy feeling, simple process flow and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

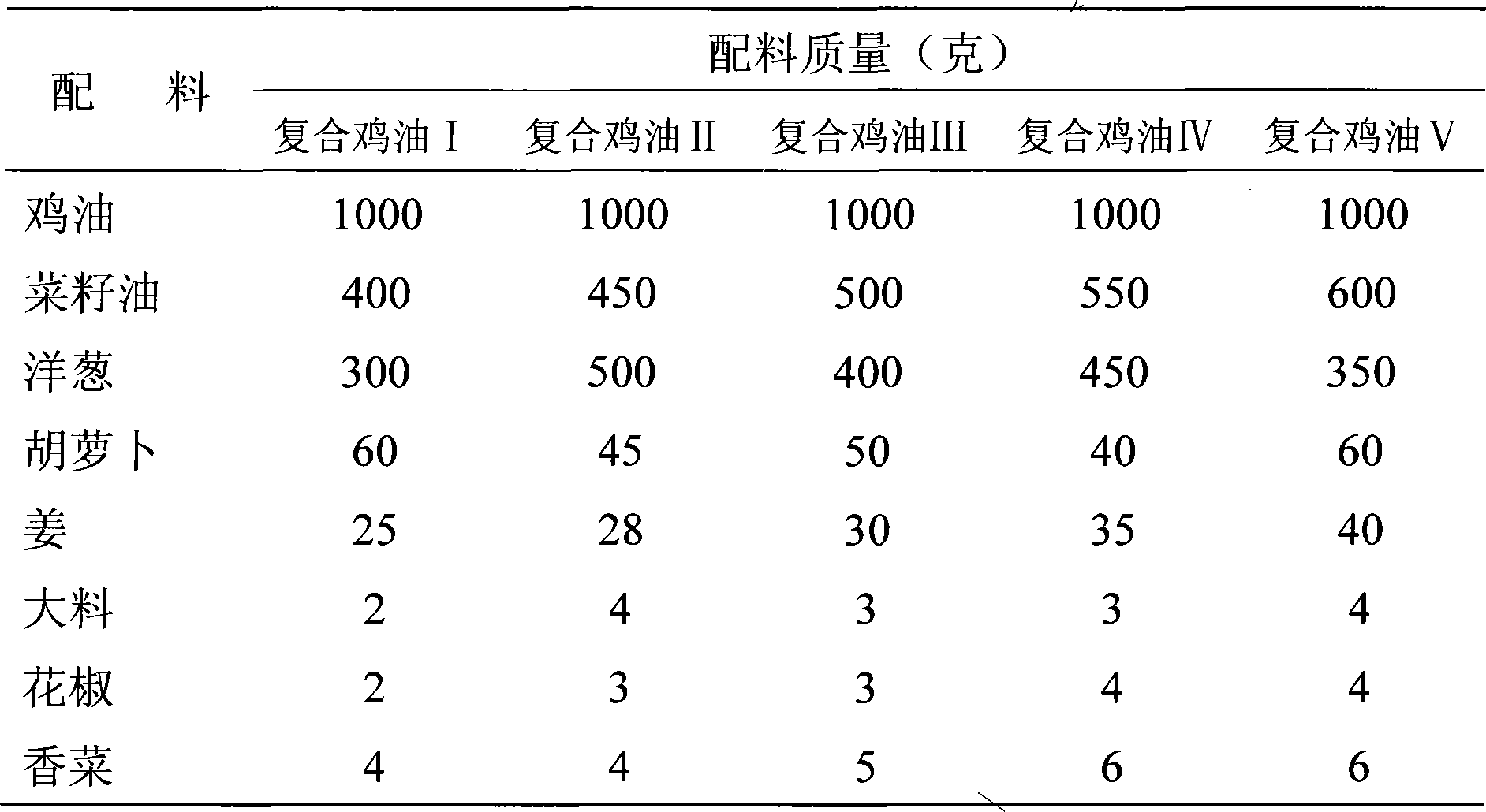

[0038] One, the preparation embodiment of mushroom powder and compound chicken oil

[0039] The two ingredients used in the preparation method of the instant edible fungus of the present invention: mushroom powder and compound chicken oil are prepared separately and stored for later use.

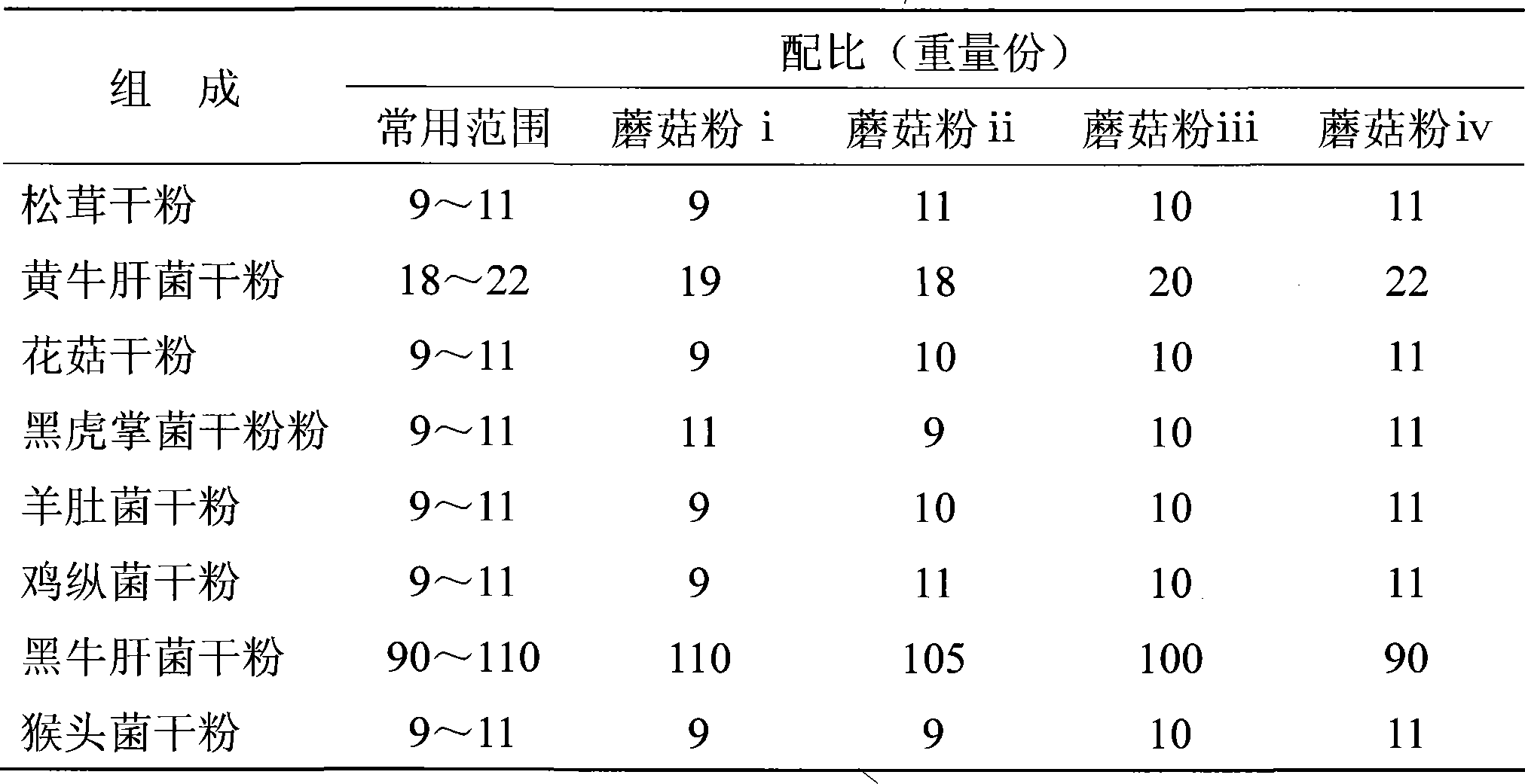

[0040] The preparation method of mushroom powder is: select the first-class fresh mushrooms of the desired species, pick and clean them, air-dry them naturally until the water content is lower than 12%, and then grind them. The particle size is 40-120 mesh. In actual production, the more commonly used 60-90 mesh; then take various dried mushroom powders according to a specific ratio, mix them evenly and store them in airtight, and take them as needed when you use them. The composition and proportioning (parts by weight) of mushroom powder are as shown in table 1,

[0041] Table 1

[0042]

[0043] In the above table, mushroom powder I, II, III, and IV are several mushroom powder formula...

Embodiment

[0048] Embodiment: the preparation method of original taste instant matsutake

[0049] Preparation method of single seasoning ready-to-eat mushroom

[0050] ① Select fresh and high-quality matsutake mushrooms, clean and shape them;

[0051]② After blanching in boiling water for 3-5 minutes, remove and control the water for about 45 minutes until no more water drips out;

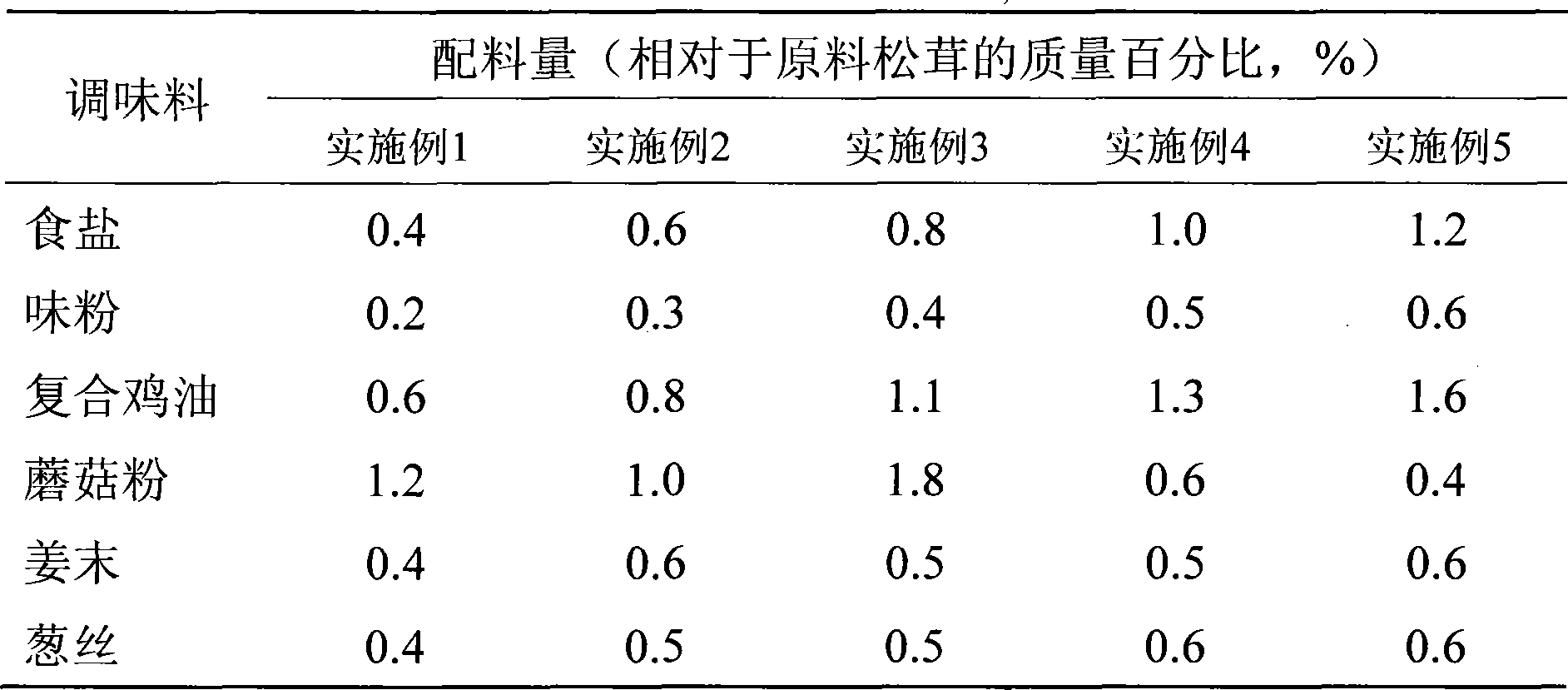

[0052] ③Seasoning: According to the quality of matsutake raw material, add seasoning according to the ratio in Table 3, seal and marinate for 20-30 minutes,

[0053] table 3

[0054]

[0055] ④Put the marinated edible mushroom raw materials into the pressure vessel, and heat at 110-120°C for 30-40 minutes;

[0056] ⑤ Product packaging.

[0057] The mushroom powder and compound chanterelle described in the preparation method embodiment of the above-mentioned original taste ready-to-eat matsutake can be mentioned in four kinds of mushroom powder (i, ii, iii, iv) and five in the first part table 1, 2 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com